Hello everyone, in this instruction we will discuss how to make a simple jigsaw machine from the engine from the refrigerator. Of course, it is intended for rough cutting, as it uses a hacksaw blade from a hacksaw for metal, and the beats are quite strong. But in general, for the economy, the machine turned out to be quite necessary, you can cut boards, plastic pipes and more.

On the basis of the engine from the refrigerator, you can assemble a jigsaw machine for finer work, if you show a little imagination and effort. On such engines there is a crank mechanism, which is just perfect for such machines. And if you also provide a lubrication system, such a machine will also be durable. If you are interested in the project, I propose to study it in more detail.

Materials and tools used by the author:

Material List:

- compressor from the refrigerator;

- profile pipes;

- Sheet steel;

- corner;

- bolts with nuts;

- steel bar;

- hacksaw blade;

- paint.

Tool List:

- ;

- drill;

- welding machine;

- wrenches, screwdrivers, etc .;

- tape measure, marker.

The manufacturing process of a jigsaw machine:

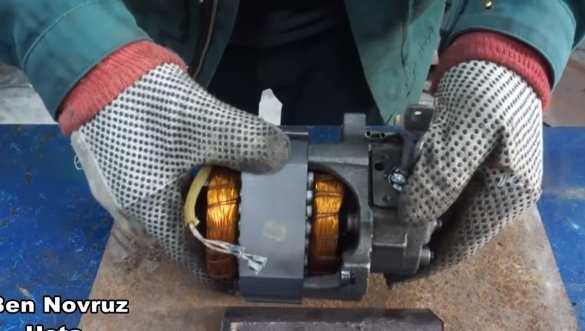

Step one. We prepare the engine

First of all, we will get the motor out of the compressor, cut the case with a grinder. When cutting, do not forget that there is oil inside, it is recommended to drain it first. We cut the tubes and get the engine.

First of all, we disassemble the assembly with the piston system, remove the valve. We need to get a steel piston, we need to weld a steel bar with an ear to it. After that, everything is going back. That's all, now we have a device with a rod, which, when the engine is running, forms a reciprocating motion.

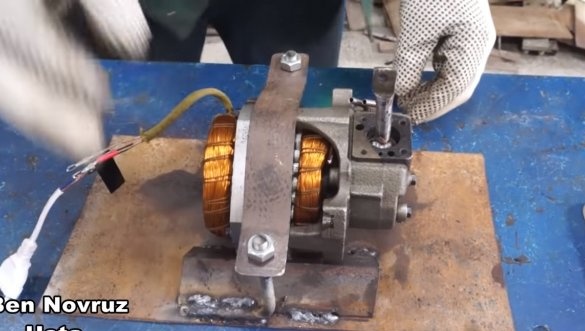

Step Two Engine mount frame

We assemble the frame for installing the engine, its design is very simple. We need two corners of the same length and a piece of steel plate, we weld corners to it with maintaining the desired distance so that the engine lies between the corners.Next, we weld two threaded rods to the base and make a steel plate, which we then press the engine to the base with nuts. That's all, after such an engine will be reliably fixed to the base.

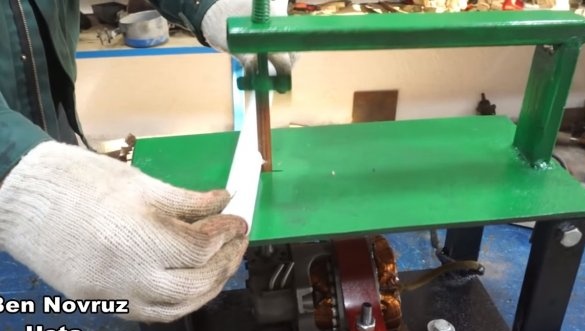

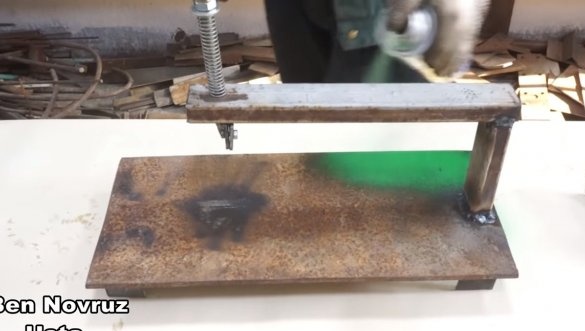

Step Three Little table

We weld 4 legs from the profile pipes of the desired length to the base. Next, on top of these legs we fix the "countertop" made of sheet steel. The author’s "countertop" is removable, it is attached with the help of corners and bolts, the corners are welded to the "countertop".

As a result, it remains to make a slit hole so that a hacksaw blade can pass. On a table for a hacksaw blade, it will be useful to emphasize to reduce the load from the piston system of the engine.

Step Four Rack

We weld a stand to the table and weld a horizontal piece of pipe to the stand, in which we drill a hole. This will be the upper support for the hacksaw blade. The hacksaw blade itself is attached to the shaft at the bottom with a bolt and nut, and at the top using a special clamp to which the stud is welded. This pin goes into the hole in the upper stop and this is the design of the machine.

The machine is ready, you can start and test. The web travel is small, so half the web is enough for installation or even less, which is quite economical. The machine easily cuts the board, as required.

Step Five Painting

We disassemble the machine and paint well. Now the car looks beautiful and will not rust. For the engine, it is recommended to make a dust cover and lubricate the friction units with grease so that they last longer.

Homemade ready, the machine is working fine, although the productivity, of course, is not very high, but for domestic needs it will be enough. That's all, the project is over, good luck and creative inspiration, if you decide to repeat this. Do not forget to share with us your ideas and homemade products.