Hello dear readers and the inhabitants of our site.

Do you like the taste and smell of smoked products? And if these products do not contain harmful flavors? And if they were prepared by you personally? I am sure that your answer will be positive.

In this article, I propose to consider the manufacturing process of smoke-cured smokehouse with a water seal. The author of this homemade product will make a smokehouse from a freon cylinder.

Necessary tools and materials.

Manufacturing process.

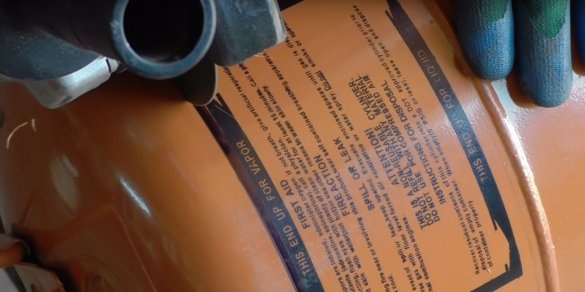

At the very beginning, you need to cut off the upper part from the cylinder. Needless to say, before starting work with the grinder, you need to make sure that there is no residual pressure in the cylinder, and also check if the gas in the cylinder was explosive. So, the author constructs a simple structure from an ordinary square and a marker attached to it.

With this peculiar tool, the author draws a line at the top of the balloon. Just placing the container on a flat surface, pressing the marker to it and rotating the container around its axis.

A flat, horizontal line is drawn, now you can cut the balloon. The edges of the cut halves are cleaned from burrs and bumps using a grinder with a petal circle.

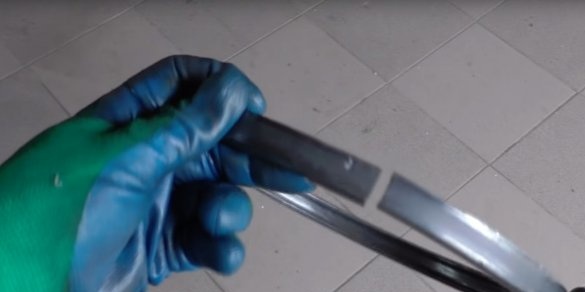

Now you can begin to manufacture a water seal. The author will make a water lock from a profile pipe 15kh15mm. The cylinder circumference is 800mm, the author cuts the profile with a small margin of 900mm.

The resulting segment must be turned into a ring, for this the author uses a homemade mini rolling machine, based on a bench vise. After suffering a little torment and sweating, the author gets a pretty decent ring from the profile. The diameter of the ring (from the center to the center of the profile) must match the diameter of the cylinder.

One side of this ring must be cut off. With the help of a petal circle, the author cleans the cut surface of the ring, getting rid of all irregularities and burrs.

With the help of a carpenter's vise, the author squeezes the ring and welds its edges. Before this procedure, make sure that the ring is put on the top of the container.

If everything is in order, you can safely cook the edges and grind the seam.

The resulting ring should be welded to the bottom of the container, with the groove pointing up. A smokehouse cover will be inserted into the groove and water will be poured.

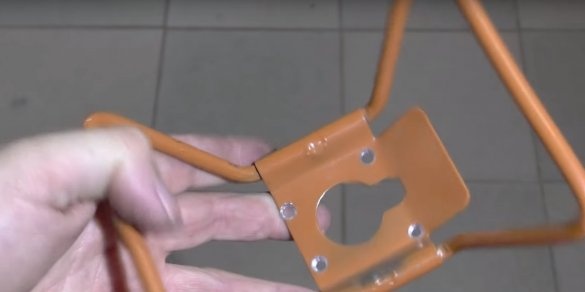

Next, you need to make handles for carrying the smokehouse, the author will use the handles from the same cylinder that remained from the previous homemade.By the way, have you already read article about her?

The author cuts the pen in half, gets rid of all that is superfluous and gets two wonderful handles.

Having cleaned the paint in the places where the pens are attached, the author grabs them with welding.

Now let's cover. On the lid there is a valve in which plastic is present. Therefore, the valve will have to get rid of. The author cuts it with a metal blade from a hacksaw, because the grinder cannot be reached for this valve due to interfering handles. The author processes the slice with a file.

Also, the author decided to increase the diameter of the hole and drilled it with a drill with a diameter of 8mm.

The author found in his stocks an aluminum pan that was no longer needed by anyone and it just fits perfectly in the diameter of the container (it should fit inside the container). This pan will serve as a pan for collecting fat.

But first you need to save her pen, which the author does.

In the center of the pan, the author drills a hole and fastens a hairpin with a ring, this will be the handle for removing the pallet.

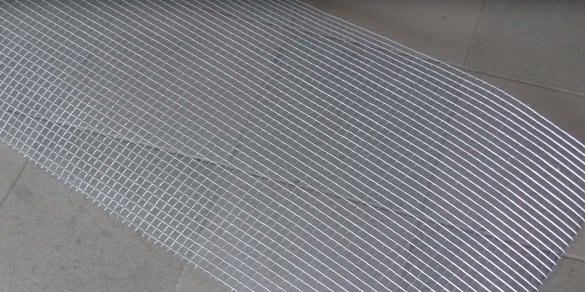

In the construction market, the author acquired a metal mesh with a mesh size of 10x10 mm. This mesh will make a wonderful grill for placing smoking products.

The author marks and cuts a circle from a grid with a diameter slightly smaller than the inside diameter of the smokehouse.

Also, having found in his stocks a piece of stainless wire with a diameter of 5 mm, the author bends it into a ring and grabs a grid to it with a semi-automatic machine. After polishing the edges of the mesh and welding, the output received an excellent lattice.

From the same wire, the author made a stand for the pallet so that the pan does not lie on the chips that will lie at the bottom of the smokehouse. The author again made a ring with a diameter of about 20 mm and welded small legs to it. The total height of the stand is not large, about 50mm.

Let's go back to the tank. In its center (along the seam) from the inside, the author welded three M8 nuts. The size of the nuts is not very important, a lattice with products will subsequently be laid on these nuts.

The smokehouse is almost ready, but before firing, you need to check whether everything is in order and whether all the details fall into place. The author makes a trial assembly. Everything is wonderful, all components of the smokehouse are well in place, you can burn the product from old paint.

The author burns the smokehouse on a lighted fire. You should wait until the old paint burns out completely.

After the product is rid of old paint, it must of course be ennobled. For this, the author uses heat-resistant paint in a spray can. Before the painting procedure, the smokehouse must of course be prepared for this, cleaned of soot, sanded if necessary and degreased.

Now the smokehouse has acquired a completely different, finished look and is ready to prepare the first portion of products.

Well, what about testing?

The author will smoke on the chips of the apple tree. We fill in a small portion at the bottom of the smokehouse, then put the support ring, on it we put the tray for collecting fat. Put the grate on the nuts.

And now the most important thing is the smoking product itself. The author will smoke pieces of fat with a meat layer. We cover with a piece of foil and cover with a lid, do not forget to pour a little water into the groove of the hydraulic seal.

We install the assembled smokehouse on hot coals and wait, we look forward to it.

In the case of the author, it took 1 hour to prepare the bacon.

It looks very appetizing, but it smells, according to the author, simply awesome, not, not so, AWESOME !!!

On the palate, I think the lard also did not disappoint.

So having few tools in the garage as well as the desire to make something and direct hands, you can make a very high-quality and attractive product in the form of a mini smokehouse. At the same time, without spending a lot of effort and finances on it, but just a little effort and time.

On this, I say goodbye to you, thanks for reading. See you soon, bye !!