Hello everyone, this time we will analyze such a useful homemadelike a tumbling machine. With it, you can easily and quickly clean rust from various parts, whether nuts, coins, spare parts, and so on. Processed materials can also be very diverse, from metals to wood and plastics. You can experiment with abrasives to achieve the desired effect.

The homemade product that the author made also works like a mill, it easily grinds steel shavings into dust, which can be used for various projects, for example, as a dye. The machine also grinds glass with ease, and steel balls are used here as “crushing elements”. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- gas cylinder or old fire extinguisher;

- gear motor (to rotate the cylinder);

- revolutions controller, switch, wiring;

- two bearings with housings;

- profile pipes for the frame;

- Sheet steel;

- a round log for manufacturing axles;

- bolts, nuts, washers;

- paint.

Tool List:

- lathe;

- drilling machine;

- tape cutting saw;

- grinder;

- welding machine;

- press;

- roulette, marker and more.

Homemade manufacturing process:

Step one. Prepare the balloon

First of all, we will prepare the cylinder, if it is an old fire extinguisher, then there will be no problems with it, just turn off the tap and pour out the contents. If a gas cylinder is used, then one must be extremely careful and carry out all the necessary operations to clean the gas cylinder. Otherwise, an explosion is inevitable when cutting with all the consequences!

Cylinders are usually filled with water and then cut, then there will simply be nothing to explode.

Turning off the tap, clearly in the center of the bottom you need to outline a point for drilling holes.

Step Two We make a frame

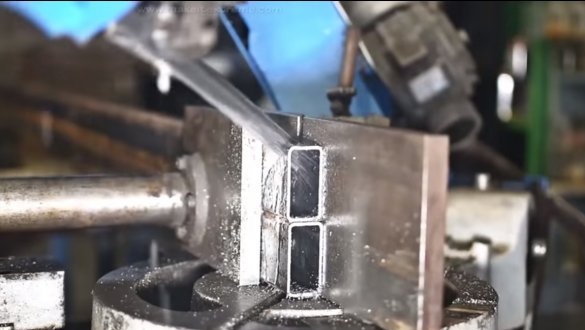

We assemble the frame for the machine, the author uses rectangular shaped pipes as materials. Conveniently, quickly and accurately they can be cut with a band saw or a miter saw. The resulting parts are well welded and we get an excellent frame.

Step Three Installation of the cylinder on the frame

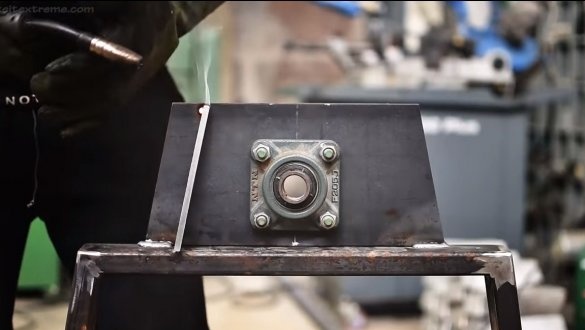

To begin with, we will manufacture two brackets and weld them to the frame, we fasten the bearings to these brackets with bolts. Brackets are made of thick sheet steel.

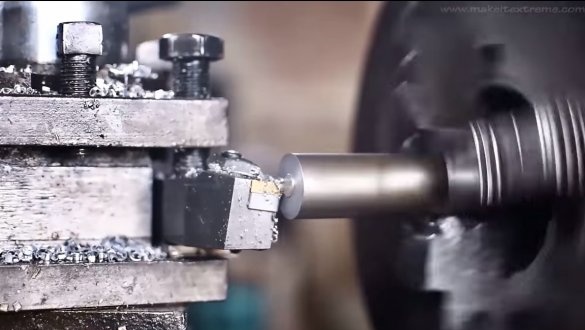

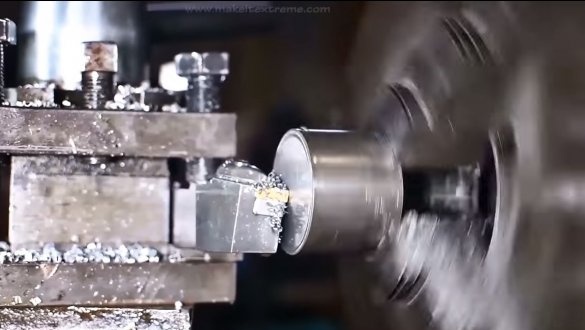

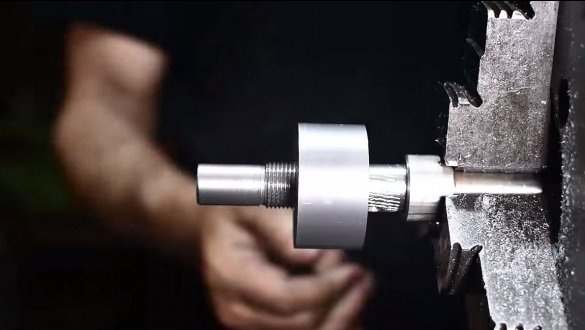

After that, you can proceed to the manufacture of axes on which the cylinder will rotate. In the bottom of the cylinder, we drill a hole with a crown and weld a nut. Next, under the nut, we make an axis on the lathe that will rotate on the bearing.

As for the second axis, it’s a little more complicated, for this axis the engine will rotate the cylinder. This axis is also made on a lathe, its design is such that it is pressed one part into the neck of the container and then welded. It turns out smoothly and firmly.

At the same step in the cylinder we cut out the window with the grinder where the door will be installed.

Step Four Engine installation

The author’s engine has a gearbox with a power of 1.1 kW, the gear ratio of the gearbox is 1 to 20, that is, the gearbox makes a revolution when the motor shaft rotates 20 times.

Under the engine we make a bracket of sheet steel and fasten it to the frame with screws so that you can remove the motor in case of something.

Step Five Refine the balloon

Small blades need to be welded inside the container so that all contents can be mixed.

Next, we will deal with the door, weld a frame of steel plates for it, drill holes and cut the thread. The author’s door is fastened with bolts, when using a screwdriver, this is all done quite quickly. The door is made of sheet steel, we attach a handle to it, it is highly desirable that there is a gasket between the door and the cylinder so that dust does not come out when the machine is running.

That's all, now we paint the whole car, it looks beautiful, and now it will not rust.

Step Six Test

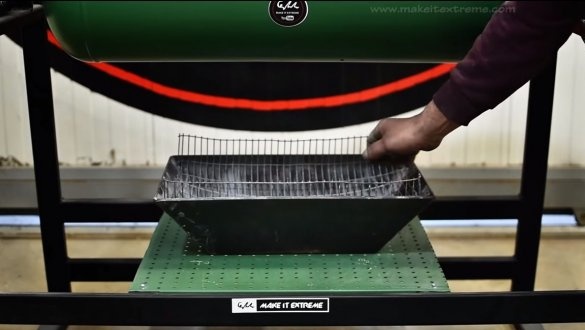

Pour steel balls into the balloon, they will work like small “mallets” when the balloon rotates. As an experiment, the author decided to grind metal shavings. Moreover, the author fell asleep not only clean balls, but also rusty, they then perfectly cleaned to shine.

We start the car, set the desired speed by the regulator and wait, here everything, of course, is achieved through experimentation. Next, we substitute a container under the container and pour out the contents, after sifting we get a metal “flour”, larger chips, as well as shiny balls.

The author also loaded glass into the container, but the result was not shown.

The device can work like a tumbling machine, as an abrasive, you can fill up small pebbles, sand and so on. The capacity of the machine is quite large, so that at a time you can polish a bunch of spare parts and other parts to shine.

That's all, the project is over, I hope you liked the home-made. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!