Do you often lose knives? Then this instruction for making a buckle-knife is just for you. Such a knife can only be lost with your pants. By the way, from the outside, it is impossible to guess that this is not an ordinary buckle, and if necessary, you can cut sausages or open a bottle of beer with such a product. So, to make a buckle-knife, you need the following

Tools and materials:

- Procurement of 420 stainless steel;

-Belt;

-Magnets;

-Paper template;

-Kern;

-USHM;

-Tape grinding machine;

-File;

-Dremel;

-Vise;

-Burner;

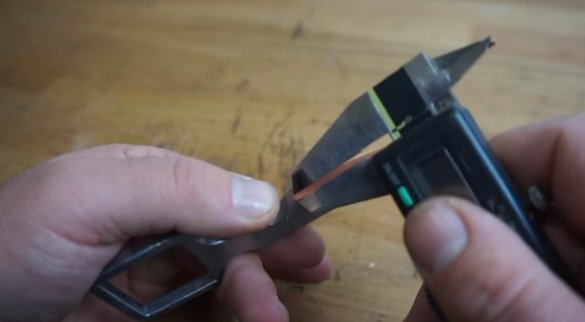

-Calipers;

-Scriber;

-Rule;

-Drilling machine;

-Gon;

-Nadfiles;

- Hacksaw for metal;

-A screwdriver;

-Device for sharpening knives;

-Bar;

-Kiln for hardening;

-Oil;

-Gas oven;

-Nail;

-Lathe;

-Hammer;

-Pliers;

-Knife;

- Clamps;

-Bandsaw machine;

-Clips;

-Kaydeks (Kydex);

-Hair dryer;

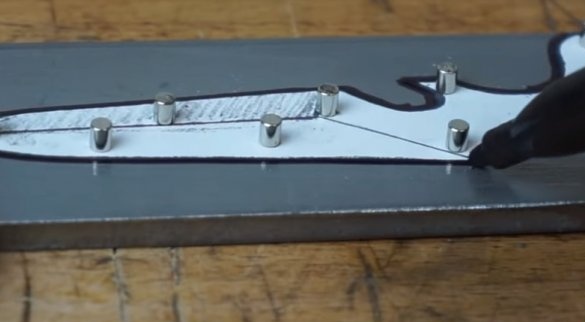

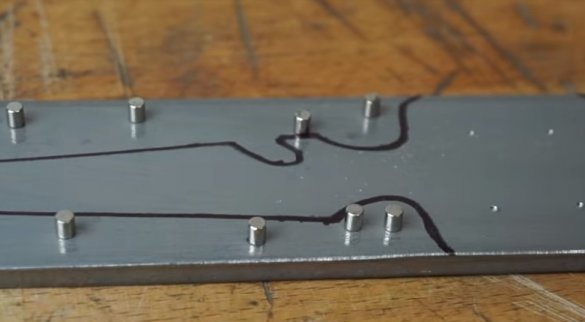

Step One: Markup

Places a template on the blank. Fixes it with magnets. Draws around the contour. Kernit by tags.

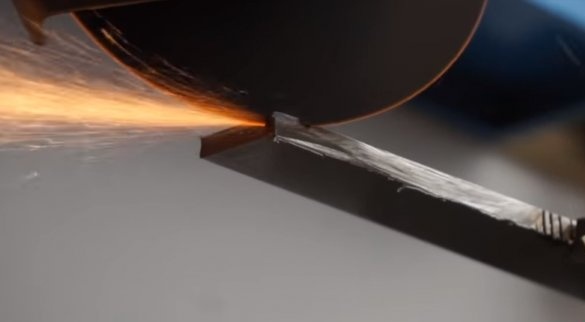

Step Two: Cropping

USHMkoy cuts the workpiece of the buckle.

Turns around the contour.

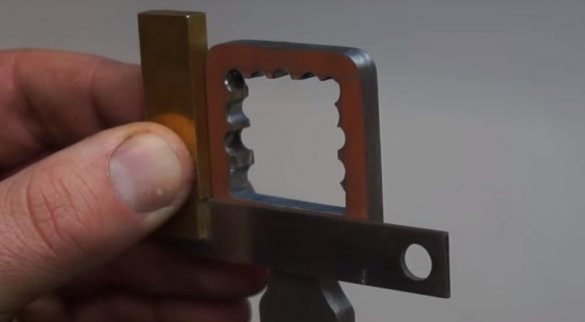

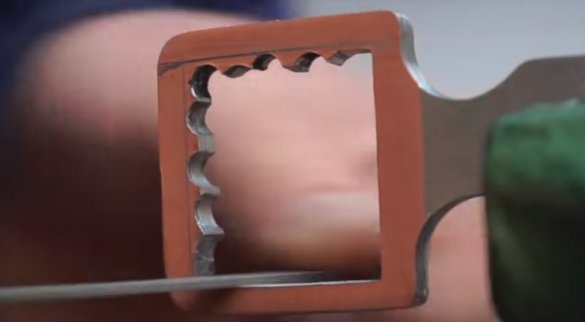

Step Three: The Eye

Now you need to make an eye in the buckle. It paints the surface and draws a caliper with a caliper.

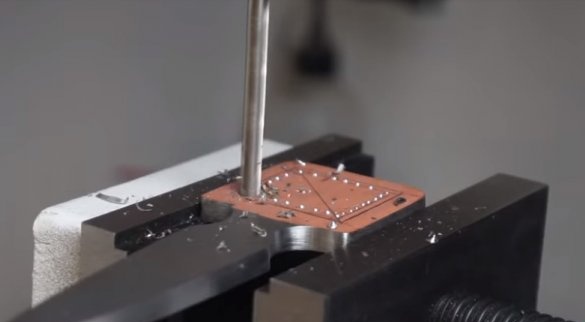

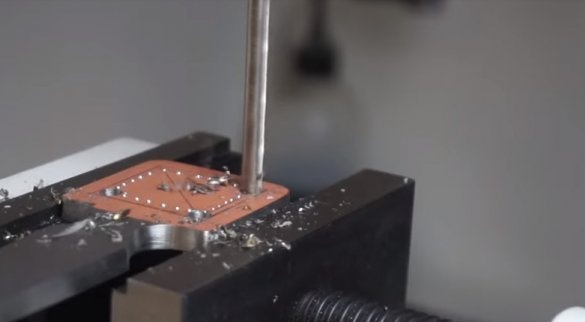

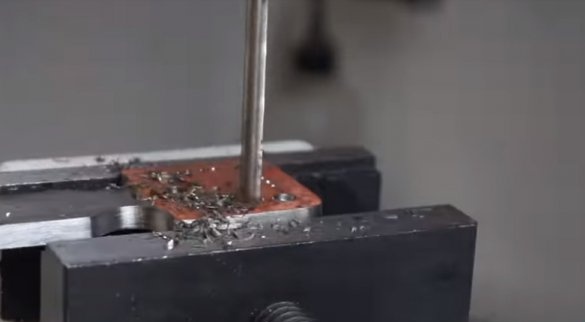

Drills along the contour.

Cuts out.

Grinds.

Step Four: Holes and Cutout

Marks and drills two holes. One hole for the nail, the other for the pin.

The neckline will play the role of a bottle opener.

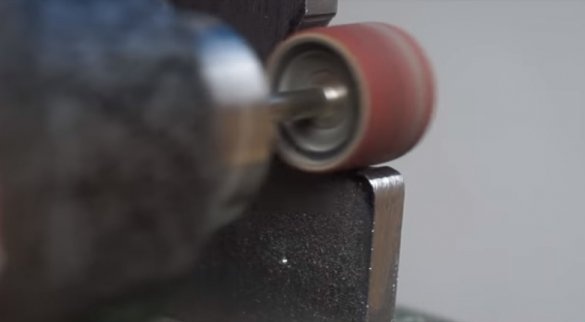

Step Five: Downhill Grinding

On the grinding machine displays descents.

Removes a step.

Sharpen the blade.

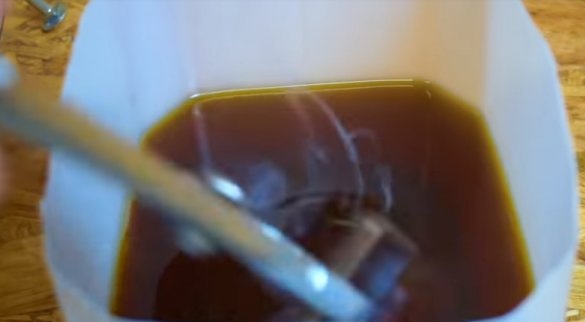

Step Six: Hardening

Further, the master hardens the product by heating it to 980 ºС-1030 ºС and cooling in oil.

After cooling, it produces a vacation. Puts the buckle in the oven for an hour at a temperature of 200 ºС. After vacation, the part cools naturally.

After hardening, the surface of the buckle acquired a matte color. The master removes it with soapy water and sandpaper.

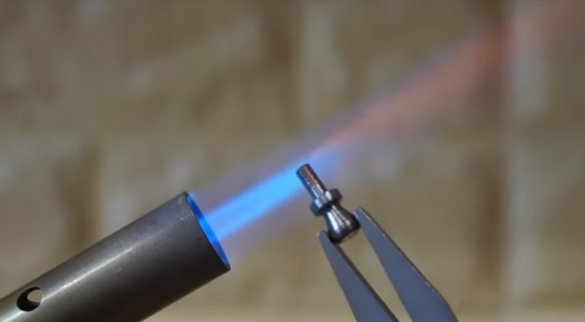

Seventh step: stopper and pin

The master makes a stopper out of a nail. Sews off a hat. Bends one end. Inserts it into the hole in the buckle and loops.

The master grinds the pin on a lathe.

Heats the end of the pin and installs it in the buckle hole.

Step Eight: Belt and Kidex

The old belt buckle must be cut off. Next, you need to punch holes along the diameter of the pin.

Now about what is Kydex. Kaydeks is a material from an American company of the same name, which, when heated, pressed on an object and then cooled, takes the form of an object. It is convenient to make knife covers from such material. The material is similar to plastic, but it has flexibility and ductility, strength and moisture resistance.

The buckle is placed on the table. A kaidex sheet is placed on the blades and heated with a hairdryer. Next you need to put a sponge on top, then a board and press it with clamps.

After a couple of minutes, the kaydeks will cool, harden and take the form of a knife. Now you need to trim the excess material and stick the cover to the belt.

Everything is ready, this interesting buckle-knife turned out.

The whole process of making a buckle-knife can be seen in the video.