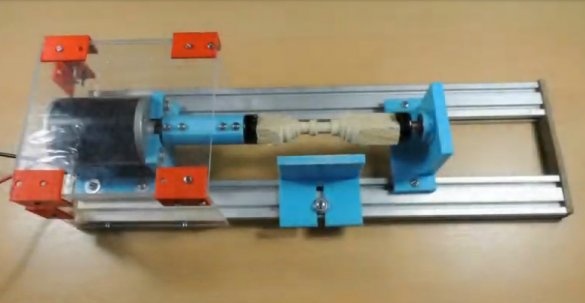

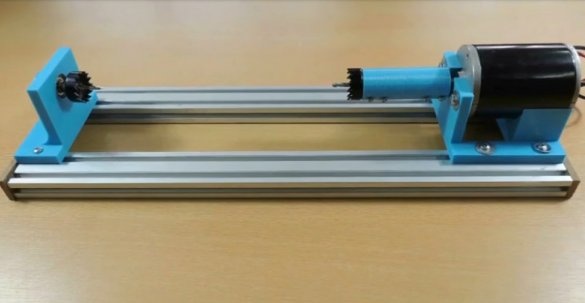

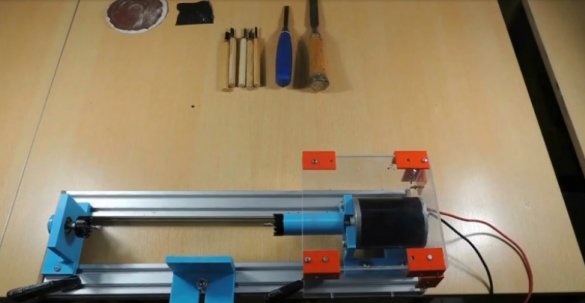

The lathe made by the master has the following features: power quietness, small size, high torque, low noise. Machine size: length 50 cm, width 15 cm, height 12 cm.

For the manufacture of the machine, the master used the following

Materials and tools:

- 12 V engine;

-Aluminum profile length 48 cm -2 pcs;

- Orgsteklo;

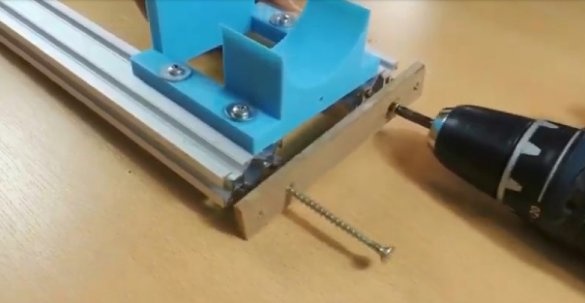

Screwdriver;

-A screwdriver;

3D Printed Parts

-Front grandmother - 1 pc;

-Tailstock - 1 pc;

-Handler - 1 pc;

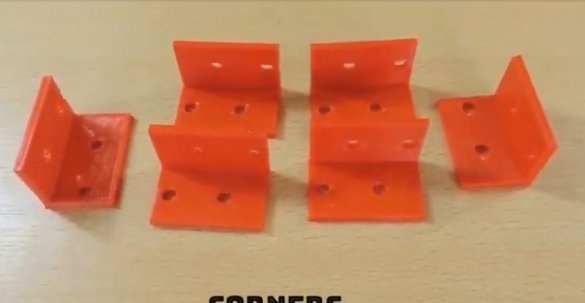

- Corners - 6 pcs;

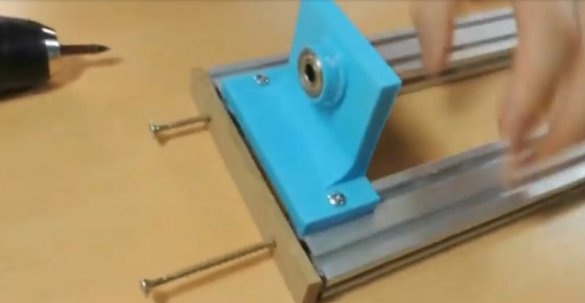

- Coupling -1 pc;

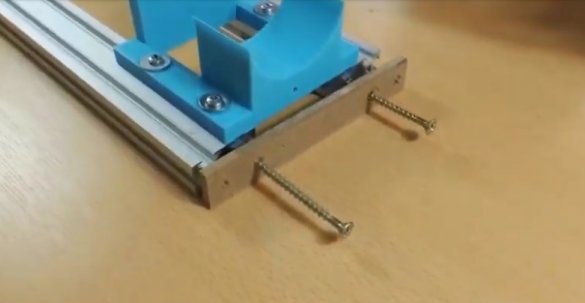

- Screws 7 cm - R: 5 mm - 4 pcs;

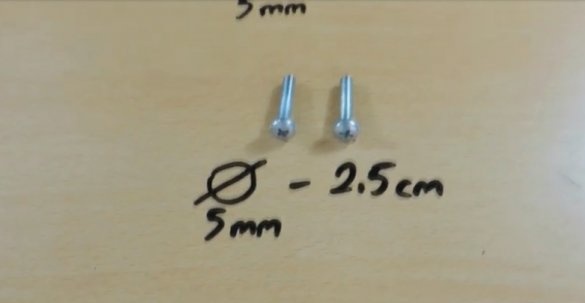

- Screws 2.5 cm - R: 5 mm -2 pcs;

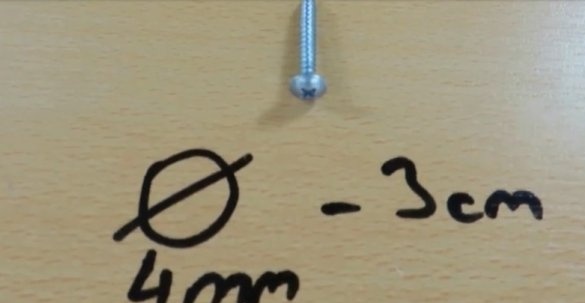

- Screw 3 cm - R: 4 mm -1 pc;

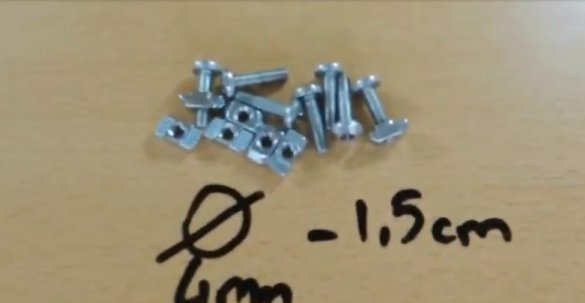

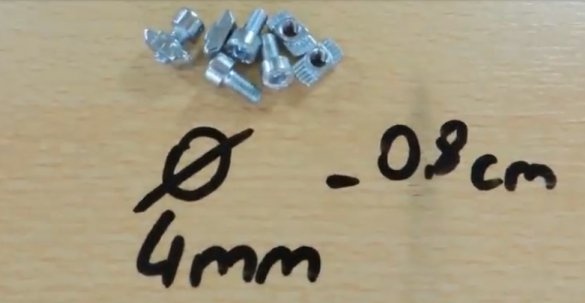

- Screws with T-nut 4 mm 1.5 cm - 8 pcs;

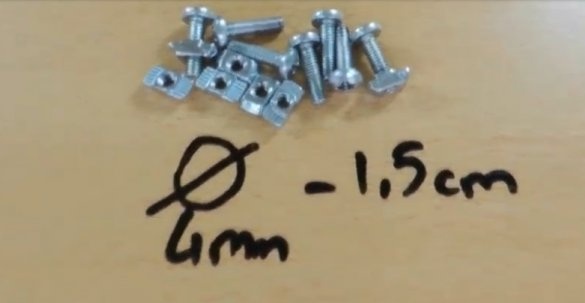

- Screws with T-nut 4 mm 0, 8 cm -4 pcs;

-Washers;

-Crowns on wood - 2 pcs;

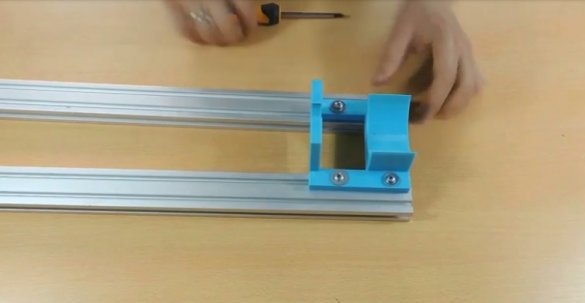

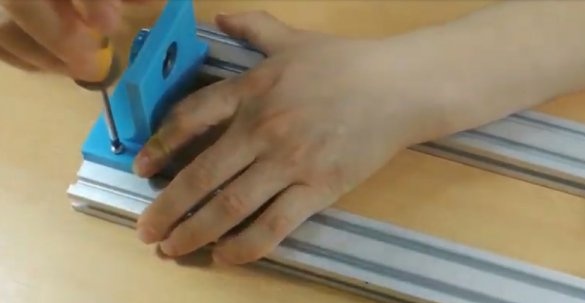

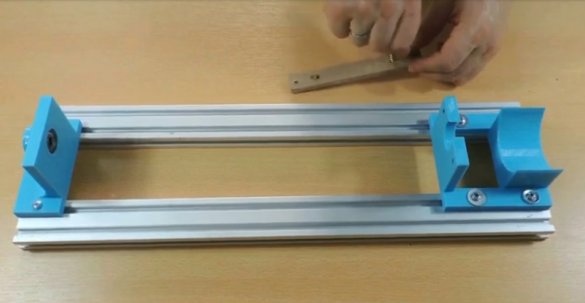

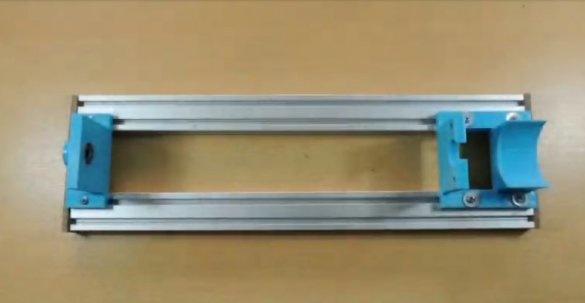

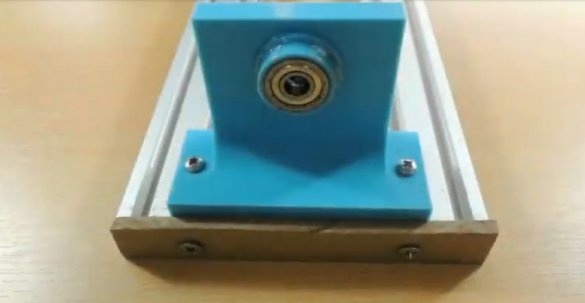

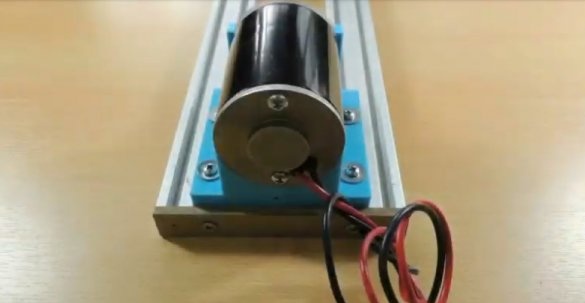

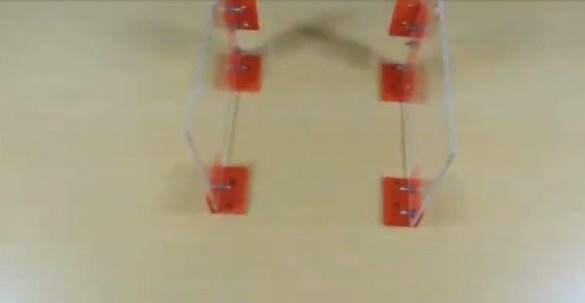

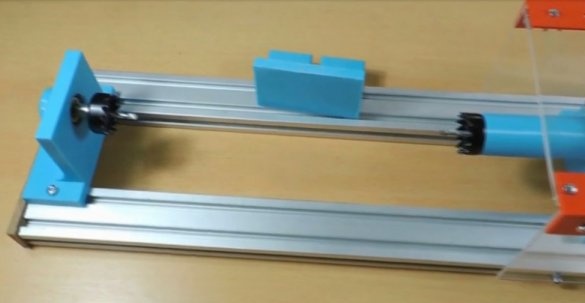

Step One: Headstock

As you probably already understood, some of the parts for the lathe are printed on a 3D printer. You can download files for 3D printing.

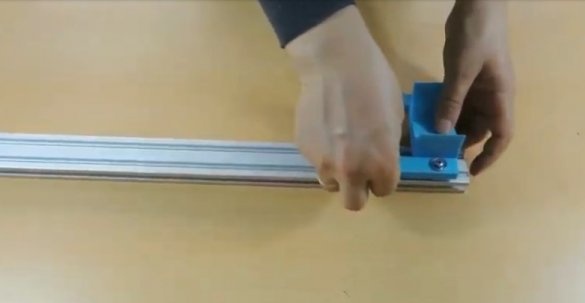

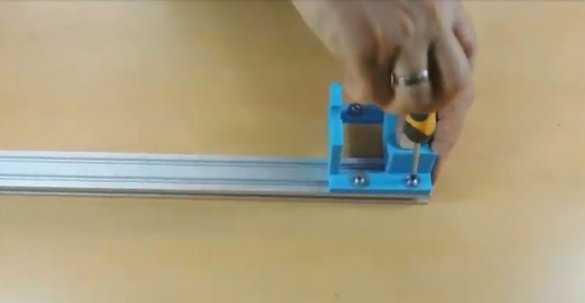

The master begins assembling, from the front headstock, the engine will be mounted on it. Installs screws with T-nuts into the mounting holes. T-nuts are installed in the guides of the aluminum profile.

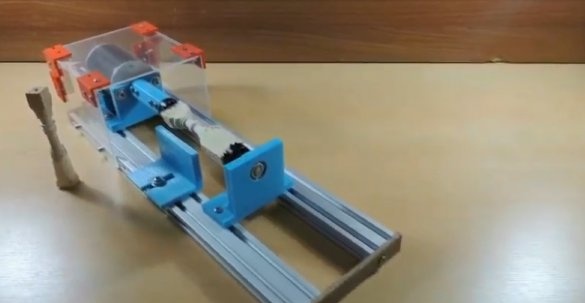

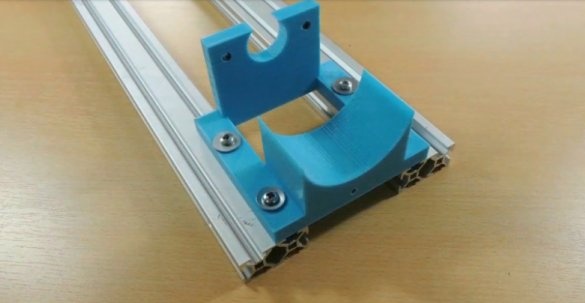

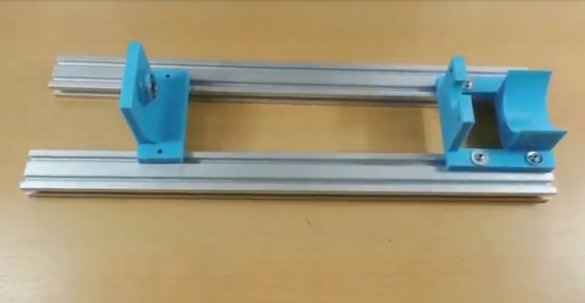

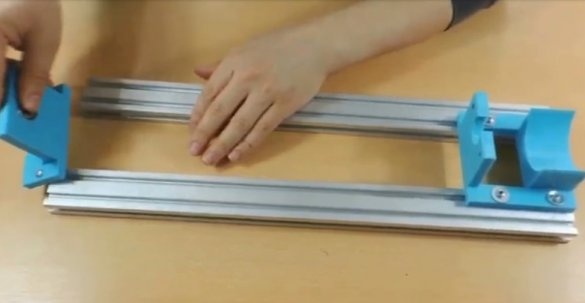

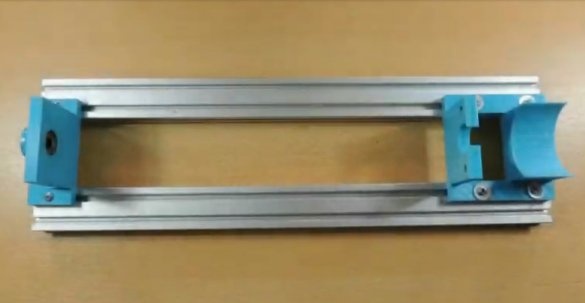

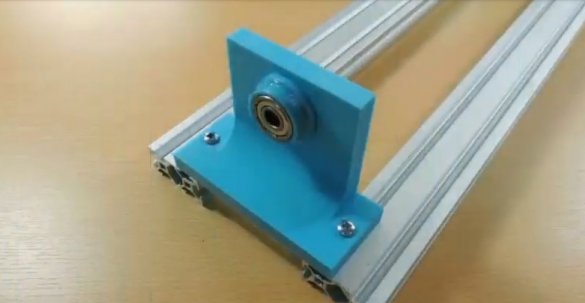

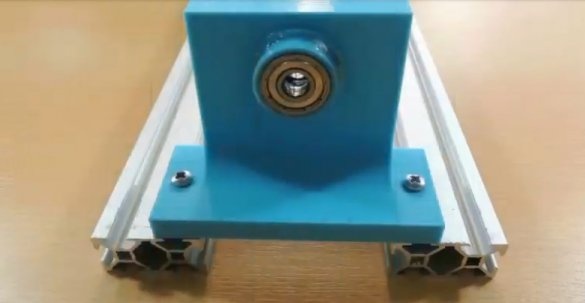

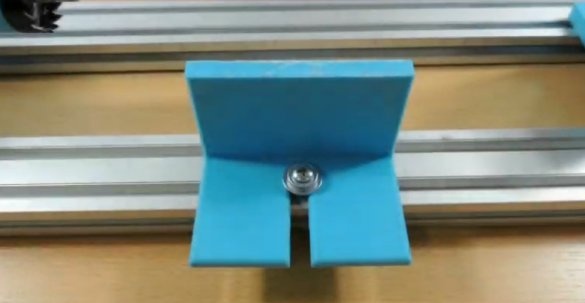

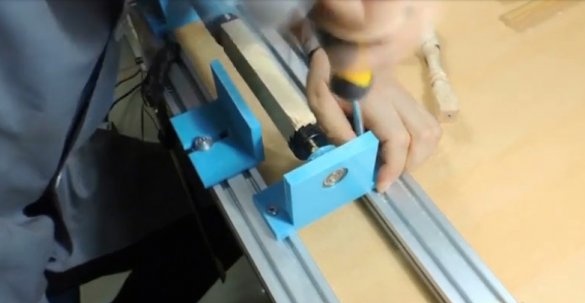

Step two: tailstock

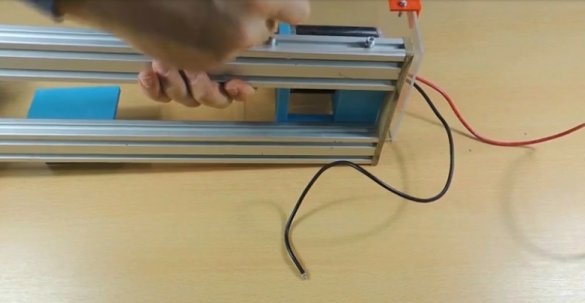

The tailstock is mounted on the chassis in the same way. The only difference is that the front headstock is screwed in motionlessly, and the back head should be able to move along the profiles.

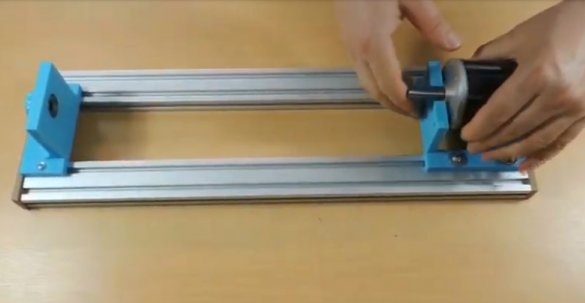

Step Three: Stubs

From the end of the profile are closed with wooden plugs.

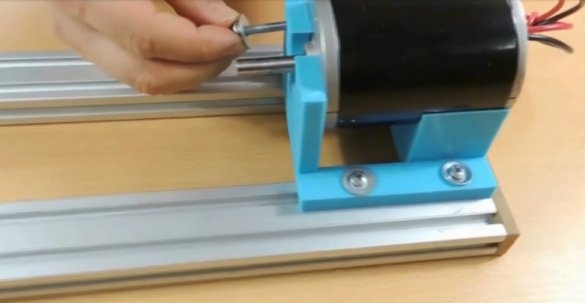

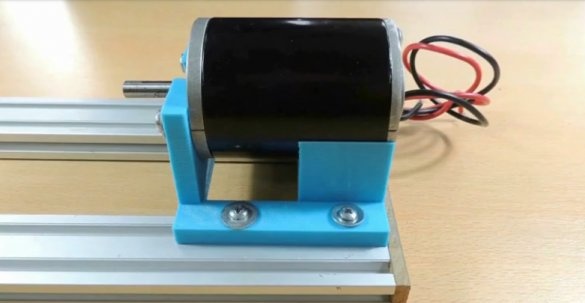

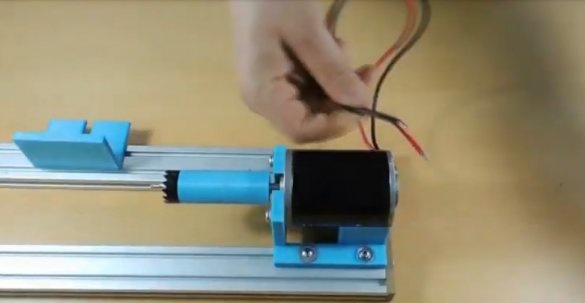

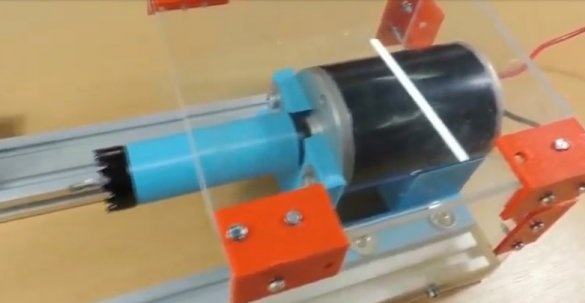

Step Four: Engine

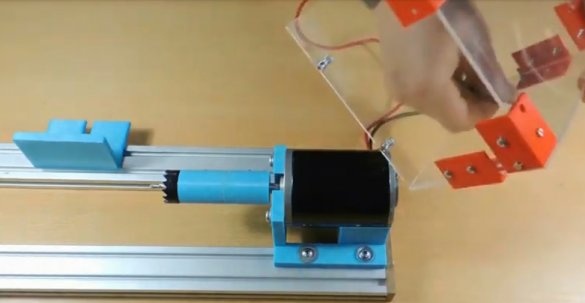

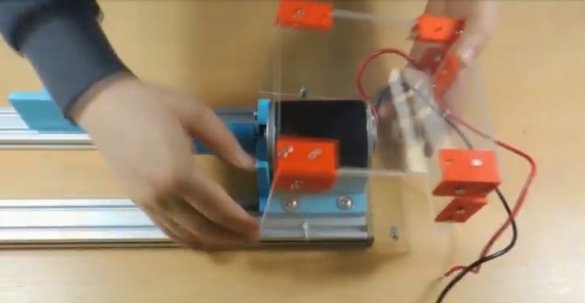

Installs and secures the engine.

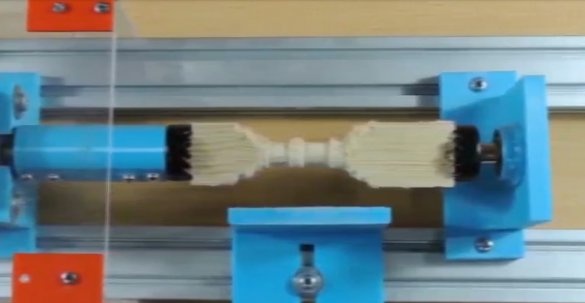

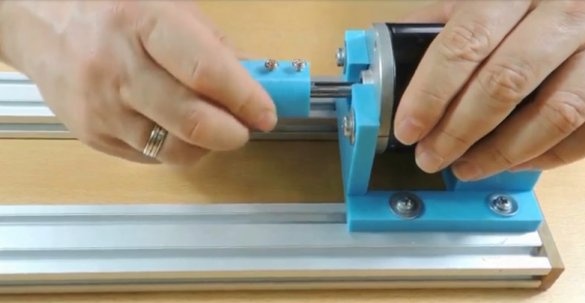

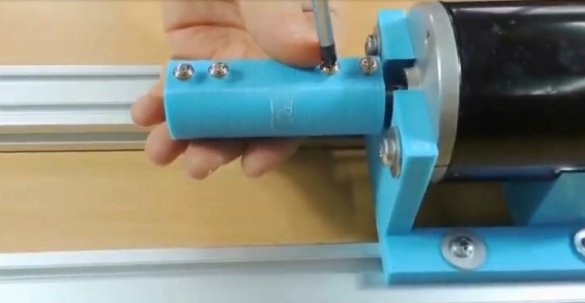

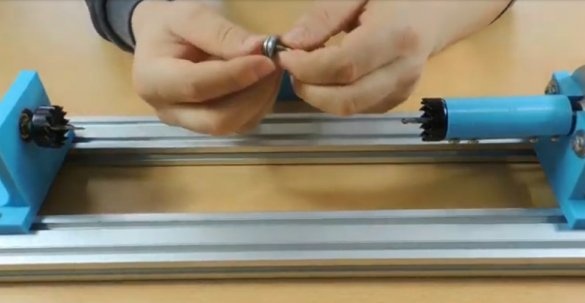

Step Five: Crowns

To fix the workpieces, the master uses wood crowns.

Fastens the coupling to the motor shaft.

Sets the crown.

Sets the rear crown.

Step Six: Handyman

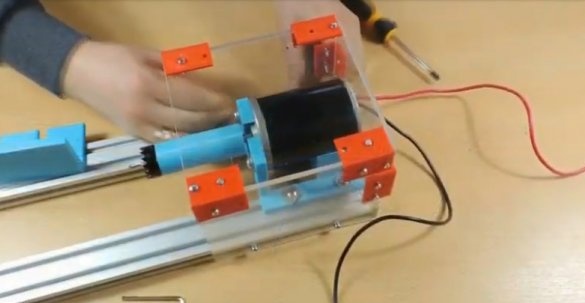

Sets the handyman.

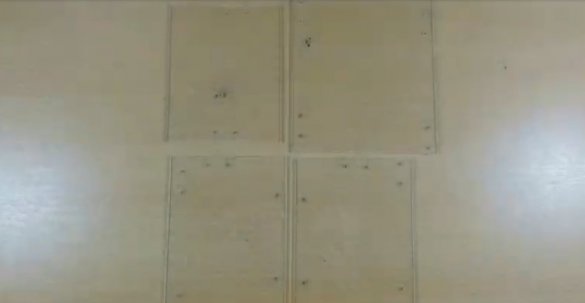

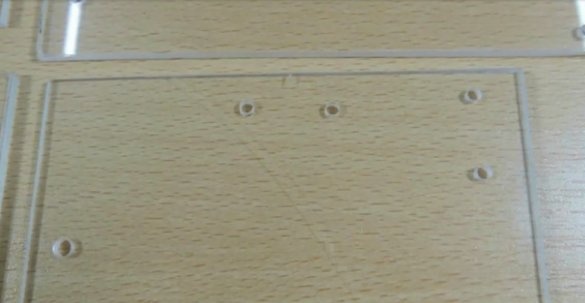

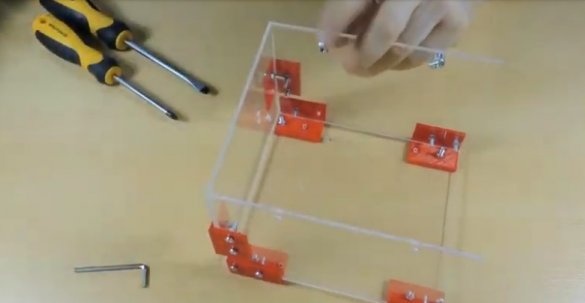

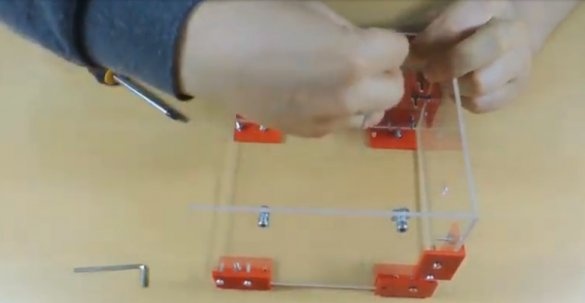

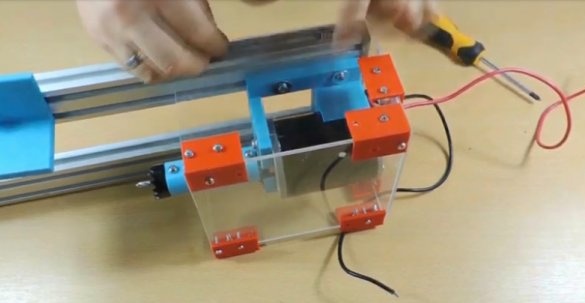

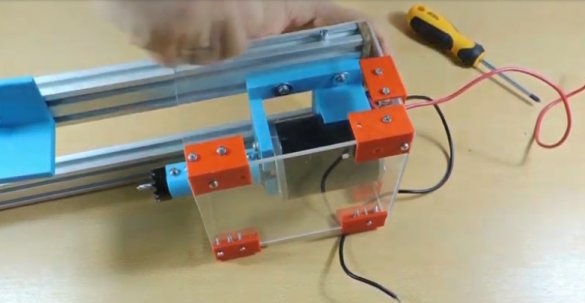

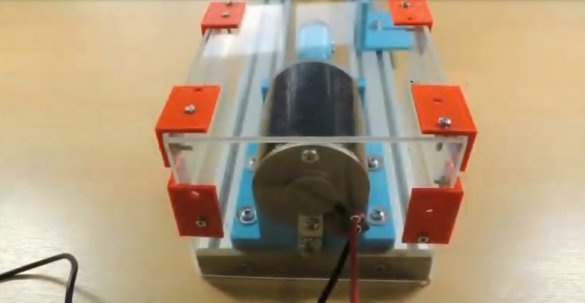

Seventh step: protective cover

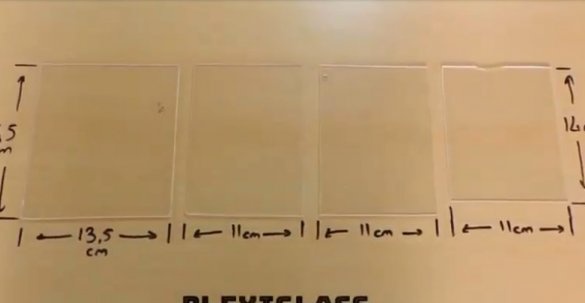

The master decided to make a protective casing on the engine from plexiglass. Cut to size:

-up (15.5 cm x 13.5 cm) -1 pc;

-sides (11 cm x 13.5 cm) - 2 pcs;

- back (11 cm x 14 cm) - 1 pc;

Drilled mounting holes.

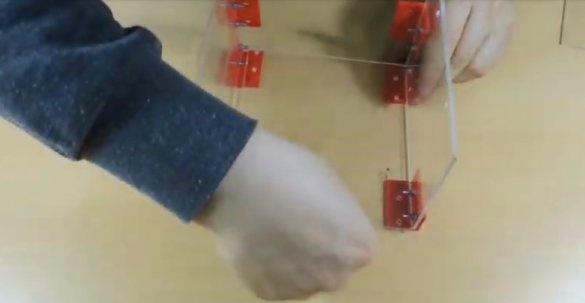

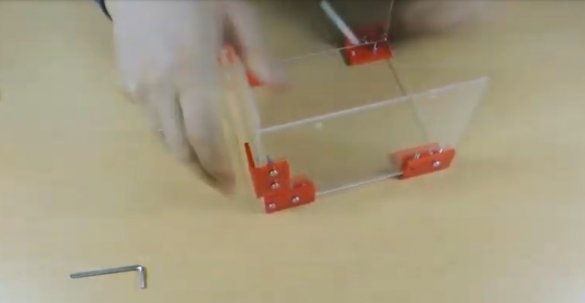

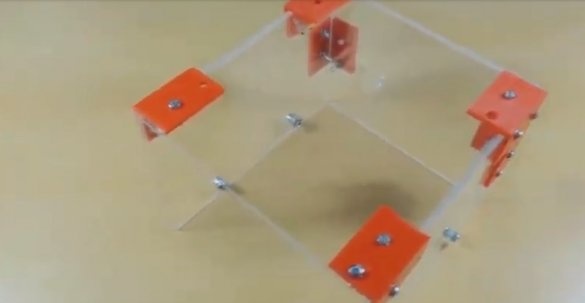

The casing is assembled using bolts and corners.

Installs and secures the cover.

It remains to connect the engine to the power supply and the machine is ready.

Now you can try to carve some detail on it. From the ends of the workpiece drills holes and clamps it between the headstock. Adjusts the position of the handpick.

Turns a part.