I welcome you dear readers and the inhabitants of our site.

This homemade product is suitable for those who use an air compressor, namely a sandblasting machine.

The author of this homemade product ran into some problem. The thing is that during the operation of the compressor, the injected air is very hot, after which it enters the cold hoses. As a result, moisture condenses in the hoses, and then enters the sandblasting apparatus. After that, the sand sticks together and this makes it difficult to supply sand to the sandblasting apparatus. the master invented and made the so-called desiccant. Which will rid the injected air of moisture, and accordingly, this homemade product saved the author from the problem.

The manufacturing process is very simple, no complicated equipment and tools are required. I propose to consider the manufacture in this article, or by watching a video.

Necessary materials and tools.

-Pipe cutter or hacksaw for metal

Manufacturing process.

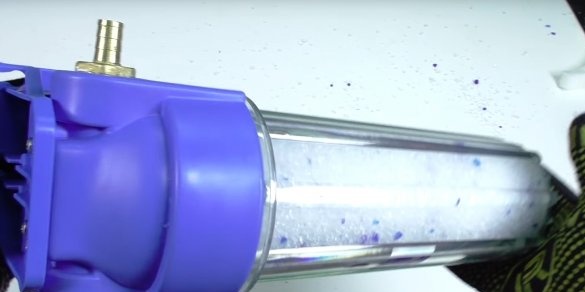

As a desiccant case, the author will use a water filter, namely his body, the filter element itself will not be needed. So if you can buy a case without a filter, you can save a lot. The housing must withstand pressure not less than 10 bar, such cases are called reinforced.

You will also need a small piece of polypropylene tube with a diameter of 20 mm. The author measures and cuts a piece of pipe, a length equal to the length of the filter element.

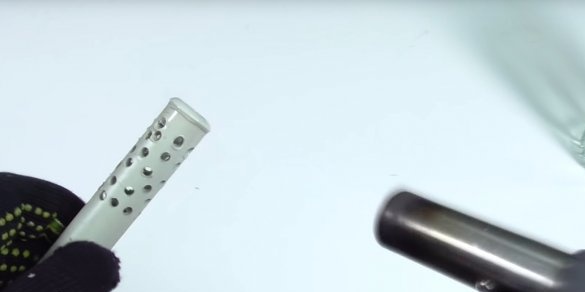

On one side of the tube, the author drills many small holes, about 3 mm in diameter. Holes need to be drilled in such a quantity that the total area of these holes is not less than the area of the inner hole of the tube itself. In general, with a margin. When drilling, you need to deviate from the edge of the tube for at least 2 cm, and leave this edge intact.

Then, using a gas burner, the author heats the edge of the tube in which the holes are made. It is necessary to heat up the very edge of the tube, and try to leave the drilled holes untouched.

Until the tube has cooled, the author quickly glues the tube into the filter housing.Inserting the tube with the heated side into the groove located inside the flask, it just fits in diameter.

Now the author will need a moisture-absorbing material, which he will place in the case. Silica gel is perfect for these purposes. Silica gel has a high absorbency (hydrophilicity), and therefore is very suitable for the author as a moisture absorber. Silica gel is able to absorb up to 50% of the water of its mass. And you can buy silica gel without difficulty, at any pet store, where it is sold as a filler, for the toilet of cats.

The author fills all the free space between the tube and the filter housing with silica gel. When pouring silica gel into a flask, dust rises from small particles of the gel, so it is better not to breathe this dust, it is not very useful for the lungs.

The author draws attention to the change in input and output in the filter cover. After altering the filter, everything will be the other way around, the input will be through the output. That is, air will first enter through the tube, then pass through silica gel granules, and then exit through the inlet. Here's a pun!))). In short, so as not to get confused, now the inlet will be labeled OUT, and the outlet with the inscription IN.

Now you need to make sure that the silica gel granules do not fly out of the flask and do not fall into the hose. To do this, the author used the usual foam rubber to seal doors and windows.

The author cut a small strip, about 20 cm, and simply fills the cavity in the lid with foam.

Now you can tighten the lid. The dehumidifier is almost ready; all that remains is to screw in the hose fittings. The author screwed them by pre-wrapping the FUM tape on the thread.

That's all, as a result, the author turned out to be a completely effective dehumidifier, or rather a moisture absorber, for a sandblasting machine.

Now it remains to attach it to the wall and boldly connect the hoses, but without forgetting about changing the destination of the entrance and exit.

On this I say goodbye to you, thanks to those who read. All good and positive. Till.