When working on an article "Soldering technology for copper water pipes" found the author JulioC150, a number of articles with tricks and tips plumbing and not only focus, and decided to share with you. Part of this material, of course, is known to visitors, part will be new, but I think everyone will be able to take note that it may be useful. Most likely, you will have to break the article into several parts. There is a lot of material, and in large blocks it will be poorly perceived.

So, let's begin.

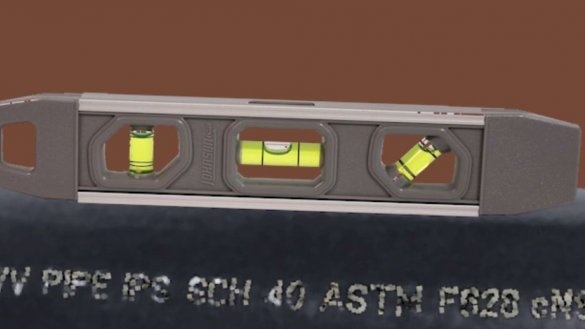

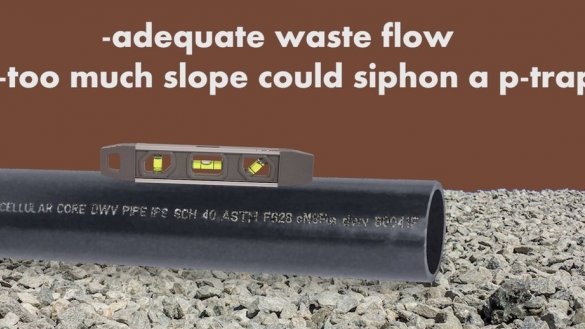

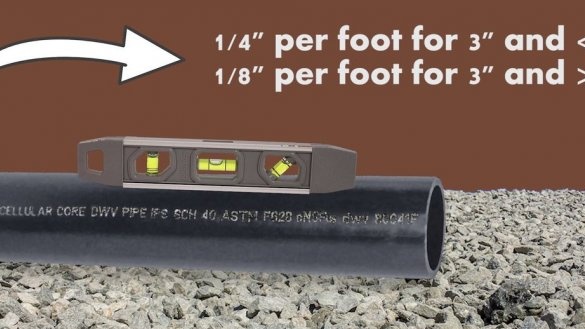

The correct bias.

When installing the sewage system, it is very important to observe the correct slope of the pipes. Ignoring this rule leads to several problems:

1. If there is insufficient slope, the sewage will stagnate in the pipes and a plug will form over time.

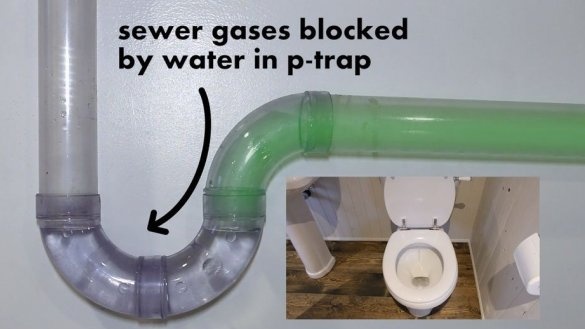

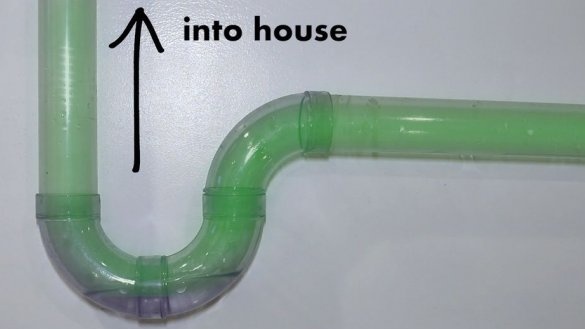

2. If the slope is excessive, run-off drains will entrain water to the blocking pipe and odors from the sewer, through the drain hole they will penetrate into the room.

3. With a large slope, the liquid effluents will merge too quickly, and the solid fractions will remain.

P.S. The correct slope of the drain pipe in Russia is regulated by SNiP and is calculated based on the pipe diameter, length, etc. You can use special online calculators to calculate.

Water hammer.

To eliminate water hammer, the master used to make deaf vertical bends in water pipes. As the pipeline filled with water, an air plug remained in these branches to compensate for water hammer. The problem was that over time, these branches were inevitably filled with water and the protection stopped working.

The master advises the use of special devices, such as, for protection against water hammer.

Solder.

If you have copper water, do not use lead solder. Lead is unhealthy. On the packaging of solder with lead there is a marking 50/50, on a safe solder marking 95/5.

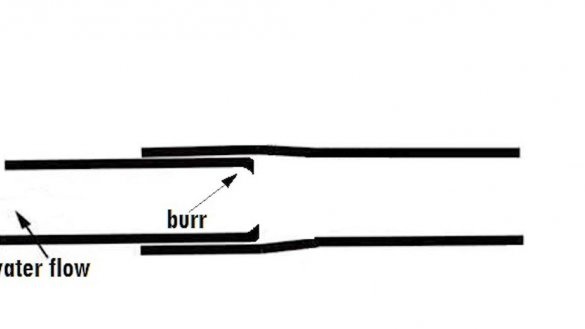

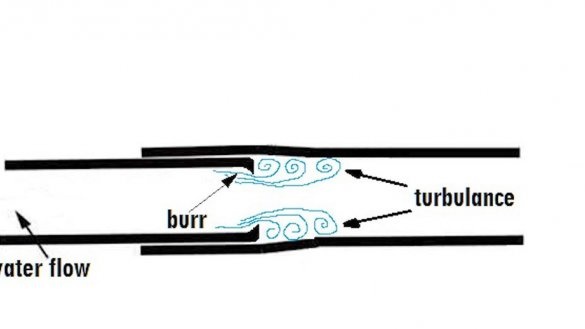

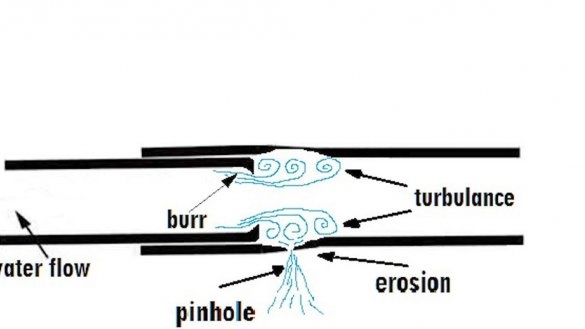

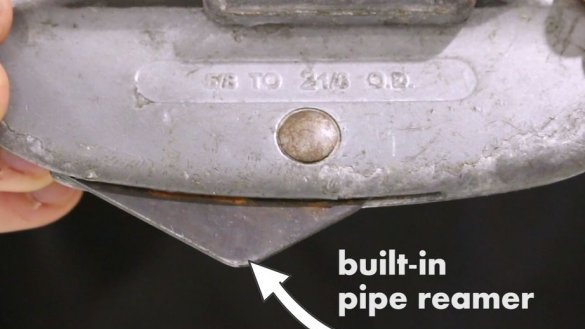

Barbs.

When trimming the pipe, the edge remains inside, which must be removed. If this is not done, then during the flow of water turbulence will form, which will eventually lead to leakage. This can be done using a special tool or a conventional knife.

Pipe cleaning before soldering.

Cleaning copper pipes (and not only pipes) before soldering is a prerequisite. During storage, the copper parts are oxidized and if the mating parts are prepared properly, the soldering will be of poor quality and over time this will lead to leaks. Another important factor for high-quality soldering is the use of solder without dirt and impurities.The master uses solder in a special bottle with a dispenser.

Suspensions.

Always fasten the pipes. If this is not done, then over time the pipes may simply break.

Fum tape or sealant?

The tightness of the connection can be provided with several materials. Some plumbers use fum tape and sealant at the same time. And here the question arises, what should be applied to the pipe first. The master advises to wrap the tape first, and only then apply sealant.

Preparing street water for the winter.

In our country, there is no need to explain that for the winter it is necessary to shut off the street water supply and drain the pipes.

But there is a special plumbing device that allows you not to worry about it. Installing a special valve will remove the problem of accidental defrosting and damage to the pipe (we will consider the operation and proper installation of such a valve in a separate article).

Winding up.

Very often, winding FUM - tapes is problematic due to the minimum distance between the pipe and the wall. The master advises rewinding part of the tape on a pencil, and then it will not be difficult to rewind on the connection.

Small hole.

Suppose that when you cut a hole in the wall, you made a mistake and cut out (a crown) a small hole. When drilling, the crown is centered with a drill. If the hole has already been cut, then the drill will not help. You can solve this problem by installing two crowns at the same time. A smaller diameter crown (which the hole was cut out) is installed inside the larger crown and with it the large crown will not slip.

Pipe alignment.

If the end of the copper pipe is flattened and does not fit into the fitting, you can align it using an adjustable wrench. Bring the key lips along the diameter of the pipe and wrap around the damaged area.

When repairing the water supply system, even if the water is shut off and drained, it continues to periodically drain. This interferes with repair, in particular soldering. To stop the flow of water, you need to roll a bread ball and shove it into the pipe. The leak will stop and this will allow to finish the job. You can’t worry about a cork. When water is supplied, it will be washed and, in extreme cases, it will be necessary to rinse the mesh on the aerator.

The first part is over, thanks for your attention.