Using this motorized machine, you can wind and tie a large number of wires, cables or similar materials.

Materials:

- plywood;

- bar;

- metal plate;

- metal corner;

- bolts and nuts;

- water pipe;

- knitting wire;

- walk-behind tractor;

Instruments:

- Circular Saw;

- wrench;

- set of wrenches;

The secret of the master coil:

He made this machine in order to wind a large number of hard galvanized wires with a diameter of 47 mm from an old neighboring vineyard. Some wires have a length of 300 m. The wires retained their “curl” from the moment they were first manufactured and installed on the transport reel, so that if they are released, they will curl up and become tangled. A tractor was used to pull several wires from a vineyard in an open field. In these photographs, the wires were untangled and the remains of the vine were removed.

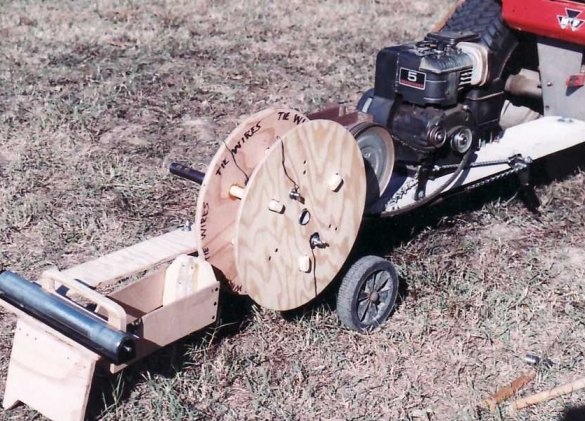

Step One: Coil Winder

The coil is made of two plywood discs with a diameter of 40 cm with three spokes. The hub is an iron water pipe. A small hole in it is intended for a bolt that fixes the winding coil in the transmission of the motoblock. The hub of this assembly carries plywood disks at a distance of 10 cm from each other.

Step Two: Removable side of the reel

Removing two nuts - lamb and washers allows you to remove one side of the coil. This function is designed to free the coil from wound wire. The ends of the spokes attached to each side of the coil correspond to holes in the other.

Step Three: The internal structure of the screw coil

The drum itself is an iron water pipe that has a piece of flat steel welded near one end and the other welded a few centimeters from the opposite end, which has a small through hole. One side of the coil remains screwed to the hub, the other side is removable. The edges of the spokes that touch the wire taper towards the center of the coil.The cone makes it easy to remove the removable side of the coil and remove the coil with a wound wire or cable from a fixed half of the coil.

Before winding a new wire onto a coil, two ties are cut into a coil, cut off from a coil of soft iron knitting wire (sold in hardware stores for knitting fittings), and their ends are secured by winding around the heads of the bolts of the sides of the coil and the wing nuts. When the coil is full and winding is stopped, the ends of the ties are loosened and used to secure the bundle of wound wire before it opens.

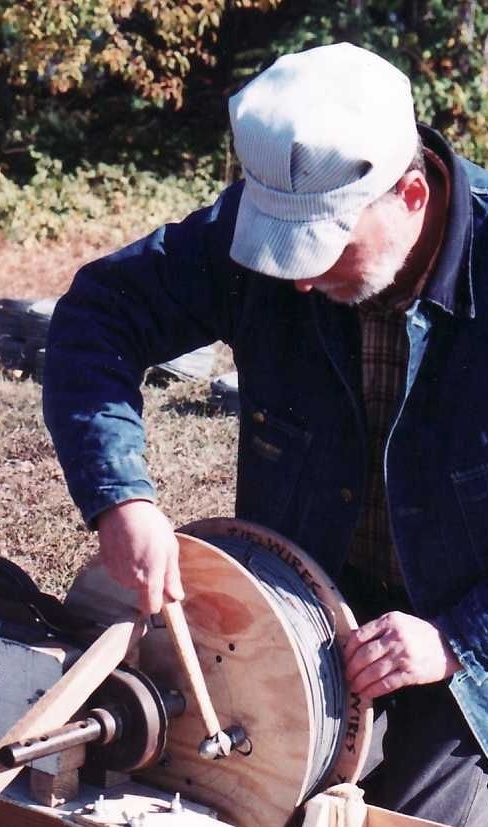

Step Four: Opening the Drum

The first step is to unscrew the nuts - the lamb. By hammering the protruding ends of the wooden knitting needles, the drum itself opens.

The long handle on the photo allows the operator to stand on one side while the machine is wrapping the wire and push the pads to pull the wire from side to side to ensure uniform filling of the coil.

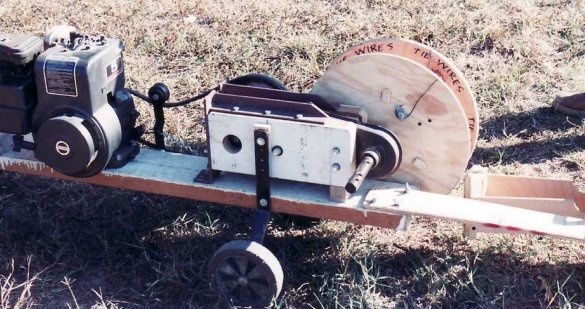

Step Five: Machine with the drum side off

View of the machine, ready to remove the coiled bay.

The wire ties securing the bay can be seen at 10 and 5 o’clock. Belt tension pulley and its working lever in neutral position.

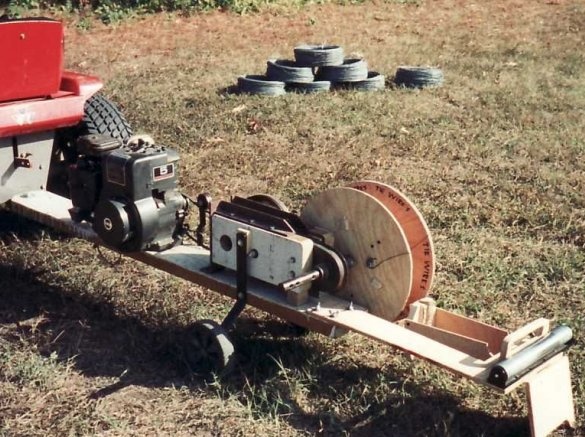

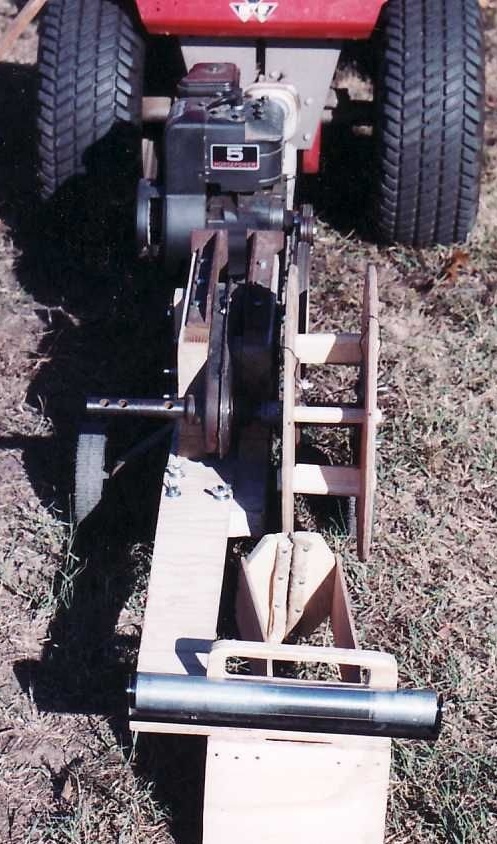

Step Six: Winder Machine

Note that the ends of the couplers are attached and ready to be wound. The coil slides along one end of the gear shaft of the transmission. The motor, wheels, spacers, as well as a belt pulley with a control lever - all this was taken from the walk-behind tractor. These parts of the winding motor vehicle were mounted on a board for the manufacture of a trailer. The coil rotates slowly at high torque. Three bolts and wing nuts attach a narrow piece of plywood to the rear of the trailer, which has a leg that supports the assembly of guides and tension pads.

Seventh step: Rear view of the winder

A shaft resting on a hinged foot is a metal roller borrowed from a conveyor belt from a rack in a store. The wire passes through long slots in the plywood to prevent it from getting off the right track as a result of excesses or twisting. Spokes of the coil and spring-loaded pads help compactly wind the cable or wire onto the coil. The pad supports are flexible enough for the operator to push the tension unit from side to side as the wire is wound using a long stick from a safe distance.

Step Eight: A Different Look at the Car

The belt pulley turns the transmission on and off. Also, the engine turns off each time the drum is opened. Many dozens of bays with cables were wound and connected for several weeks.