Hello everyone, in this article we will discuss how to make a powerful portable water pump. With it you can wash car near a lake or river, pump water from somewhere, draw water from a shallow well, and so on. The power source for the pump can be a car battery, as the engine used is powered by 12-24V.

The design of the pump is very simple, everything is made of plumbing parts that can be found in any hardware store. As for the engine, then the world famous masters are used, which is easiest to order from China. If homemade Interested in you, I propose to study it in more detail.

Materials and tools used by the author:

Material List:

- ;

- switch;

- wires;

- power supply or battery (12-24V);

- a piece of rubber from a bicycle chamber;

- conical detail made of PVC 63x32 mm;

- plug 63 mm;

- a piece of pipe 32 mm and another 25 mm;

- plug 50 mm;

- ;

- corners for pipes;

- epoxy adhesive;

- Super glue;

- screws with nuts.

Tool List:

- a hacksaw for metal or a small miter saw;

- sandpaper;

- drill;

- drill;

- screwdrivers;

- scissors;

- marker;

- drawing instruments.

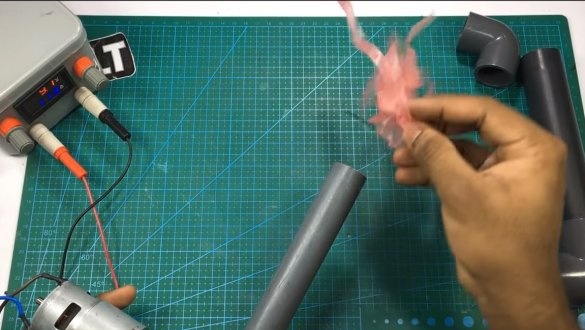

Pump manufacturing process:

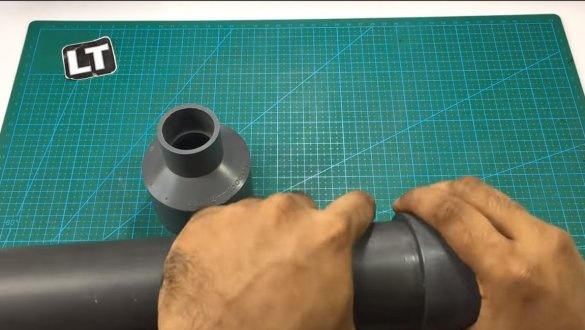

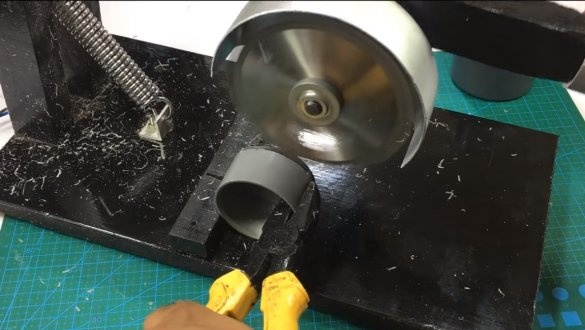

Step one. Housing

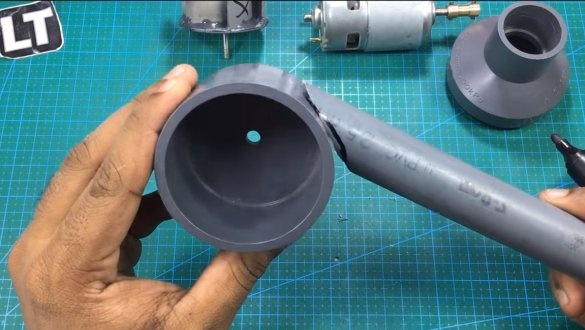

First of all, we will make a pump housing, the impeller will rotate in it. For the manufacture of the body you will need a cone-shaped part, as well as a plug for pipes. A piece must be cut from the cone-shaped part to get the body of the desired length. Next, the plug and the manufactured part must be connected, for these purposes we need a piece of plumbing pipe of suitable diameter.

We cut off a piece of the pipe and glue it onto the epoxy glue in a cone-shaped part, until we glue the plug, since we still have to make an impeller.

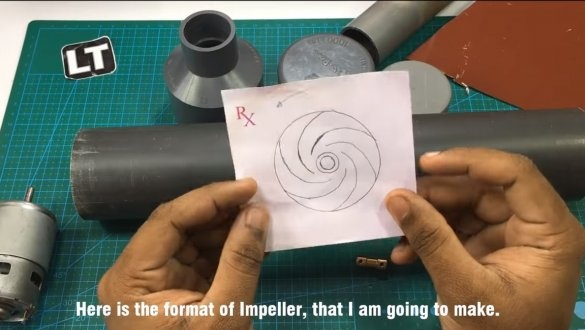

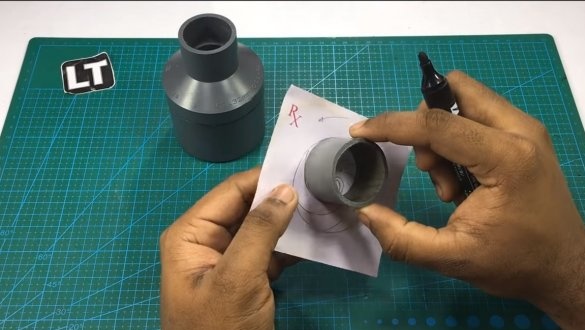

Step Two Impeller

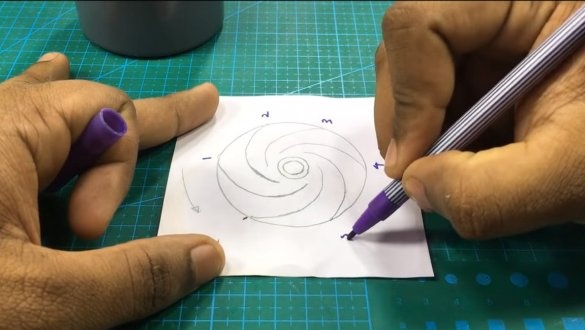

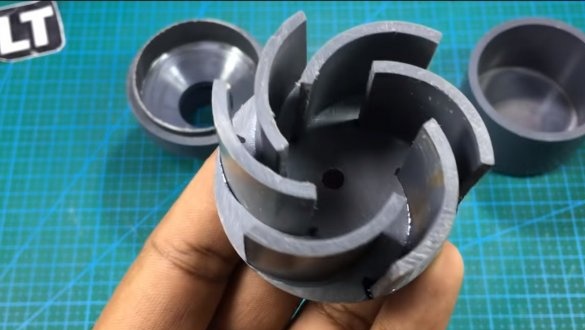

We will have a centrifugal pump, we will make an impeller for it. First you need to cut a circle of sheet metal, this will be the basis for the impeller, and thick sheet plastic will do.

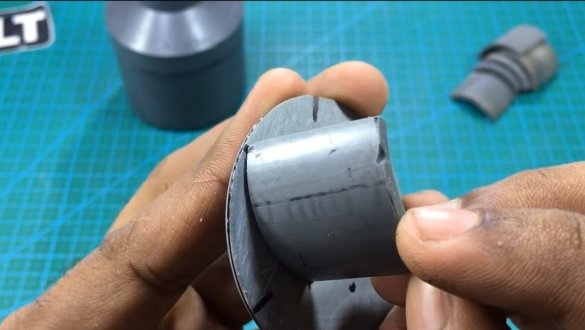

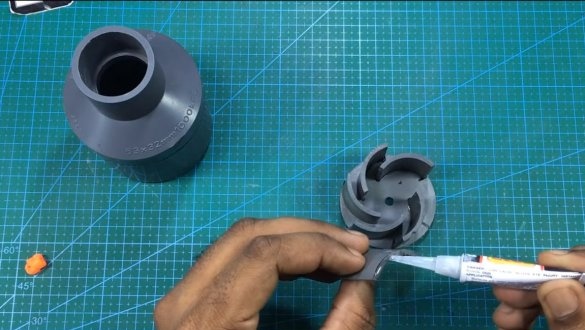

Next, you need to make the blades, their author cut from the plugs for pipes by 50 mm, you just need to mark everything up first. First we glue the blades to the base with superglue, and then finally fix everything with epoxy glue.

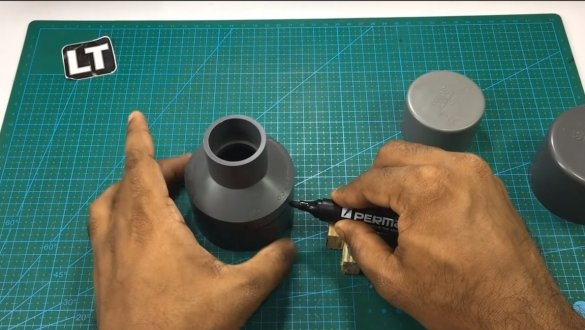

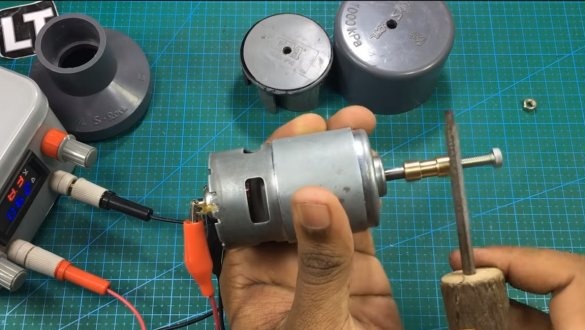

It remains to make an axis for the impeller, its author makes it from a screw, a part of the thread must be removed from it, this will be the part that will rotate in the gland.

Step Three Outgoing pipe

We prepare the outgoing pipe, it will need to be fixed at an angle. To install the pipe in the pump body, we make a hole of the desired shape and diameter, it is useful to have a drill here. Such a hole can be cut with a soldering iron, a drill, then modified with files. The author plans to stick the pipe with epoxy glue.

Step Four Stuffing box

For the pump, you need to make an oil seal, otherwise water will pour on the engine, which is unacceptable. For these purposes, the author adapted a piece of rubber from the bicycle’s camera, but it’s better to take gum thicker, for example, from a car camera.

We cut a round log and drill a hole for the axis of the pump, the hole should be smaller in diameter than the shaft to ensure good tightness.

We fasten the gland with the same screws that secure the engine. For additional fixation, glue the gum along the contour with epoxy or other glue.

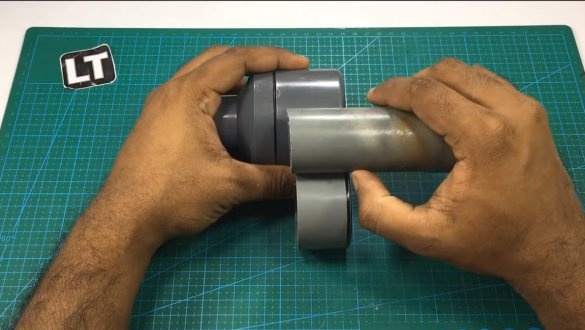

Step Five Pump assembly

We install the engine, it rests on two long screws that are screwed to the pump casing. The pump shaft and the motor shaft are connected through a special adapter, a switch is installed on the motor.

Glue the outlet pipe to the body with epoxy glue, and the inlet can be installed on the sealant. Set the desired bends using pipe angles and pipe pieces.

The pump is ready, we connect the power to 12-24V and try the device in practice, it is important not to confuse the direction of rotation of the impeller, otherwise the pump may work in the opposite direction. The device perfectly pumps air, homemade can be used as well as a blower. The water pump pumps perfectly, the pressure is quite strong, high performance.

I hope you liked the homemade product, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!