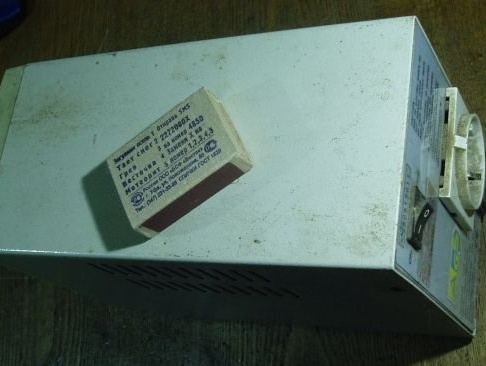

Once I got an old uninterruptible from a computer for parts. But I did not disassemble and dispose of it. I decided to make him a charger for car batteries, especially since the power of his transformer for this purpose was quite enough.

I made chargers from old uninterruptible power units several times, but it was completely ugly crafts whipped up, assembled on a plank, without adjustment and even without a fuse. The site even published one of them

Of course, somewhere in the forest, in the village 100 km from the city, a dead battery, if absolutely necessary, you can try to charge from anything, but for constant use you need a good and safe design.

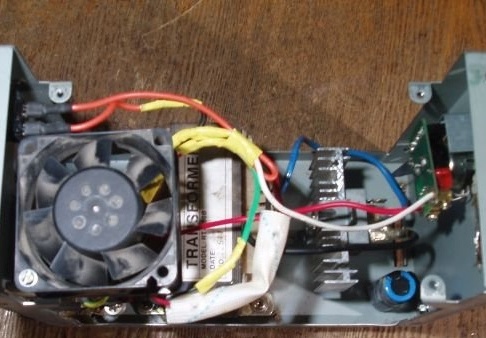

We disassemble the uninterruptible system and remove everything unnecessary. We leave the network connector with a fuse, an output socket (still useful), a transformer, a switch.

You will also need a powerful diode bridge with a radiator, a 4700 uF 35V capacitor, a cooler from a computer (but this is not necessary), a microammeter (I got from an old cassette), a shunt of about 0.3 Ohm and a dimmer. A dimmer is the most common, used to adjust the light in the rooms, at 300 watts.

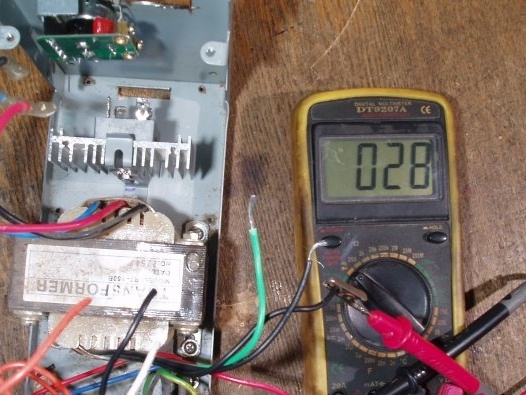

First you need to check the transformer. We find in it the winding with the greatest resistance. This, most likely, was an output winding, with a voltage of 220V.

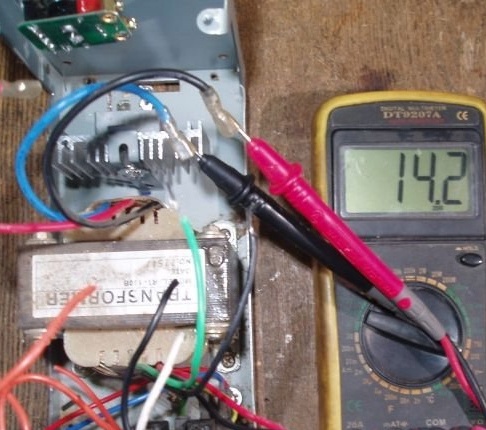

Now it will be the entrance. We apply voltage to it from the outlet and measure how much it will be at the output.

It turned out 14.2V. alternating current. After rectification on the filter capacitor, you get about 19V.

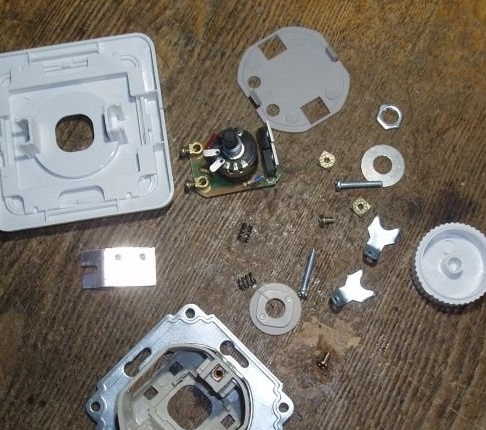

We are taking apart the dimer, we only need it electronic filling with regulator.

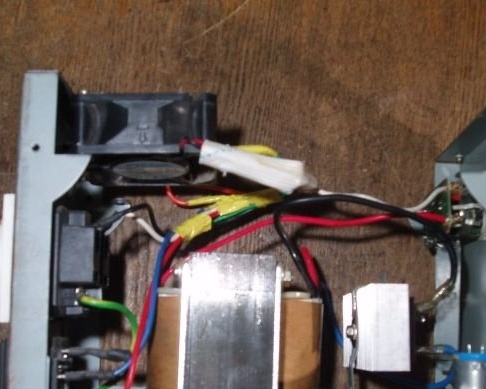

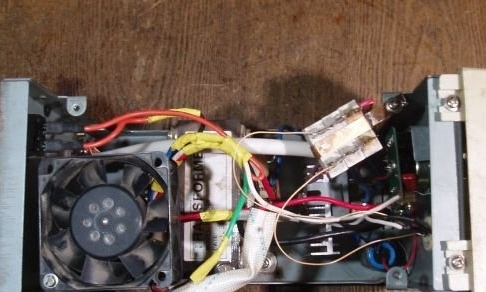

Well, then everything is simple. By corners and screws with nuts we fix all these spare parts in the housing and connect all the above spare parts.

It makes no sense to give a connection diagram, because there is nothing complicated in it.

The socket, which used to be an uninterruptible power outlet, is soldered directly to the network connector, and now simply acts as an extension cord.

The dimer is included in the gap of the network wire, in series with the network switch, and regulates the voltage at the input of the transformer.

The transformer output is connected with its terminals to a diode bridge, on which there is a corresponding marking: ~, +, and -.

The filter capacitor is soldered directly to the terminals of the diode bridge, according to its polarity. The wires from the fan are soldered here, red plus, black minus. From the diode bridge, the blue “minus” wire goes directly to the “minus” of the battery.

A positive brown wire from a diode motor is soldered to a shunt assembled from three parallel-connected ceramic resistors with a resistance of 1 (one) Ohm. The result is 0.33 ohms. Power resistors 5 watts. From the output of the shunt, the brown wire goes to the "plus" of the battery.

The microammeter wires are soldered directly to the terminals of the shunt. The microammeter itself is fixed to the plastic front panel using hot melt adhesive. The holes in the plastic panel for the microammeter and the dimmer knob are made with an ordinary knife. The regulator knob is fastened with the same hot glue.

The battery is connected with special collet terminals purchased at the car shop on occasion.

Before turning on the charger, connect the battery (strictly observing the polarity!), And turn on the device.

By adjusting the input voltage, the battery charge current is selected at the level of 5..5.5 A. This corresponds to the charging current of a 12-volt car battery for 55 ampere-hours. With the indicated shunt resistance (0.33 Ohms), the needle of the microammeter (current of its deviation according to the passport is 1 mA) will just be in the middle position of the scale.