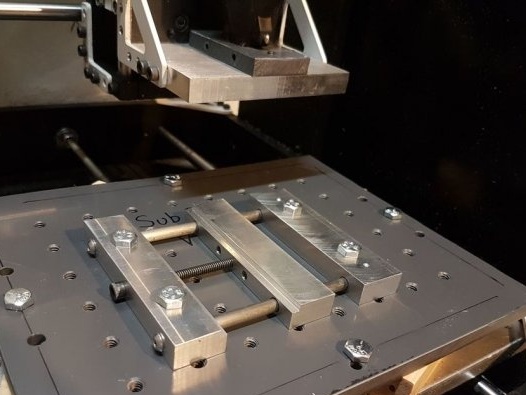

The master has a small CNC milling machine. He made the machine himself. During its operation, there was a need to install a vise on the machine to hold the workpiece. All vices on the market are not suitable for size. Then the master decided to make a vise on his own.

Tools and materials:

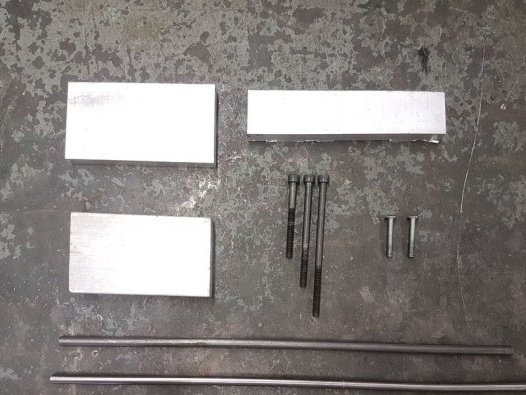

- Aluminum flat bar;

-Aluminum rod;

- Drill rod - Ø0,250 "(different lengths)

- Screws with a cylindrical head;

-Manual milling machine;

-Bandsaw machine;

-Drill;

-Scan;

-Drilling machine;

Cutters;

- Files;

-Tapers;

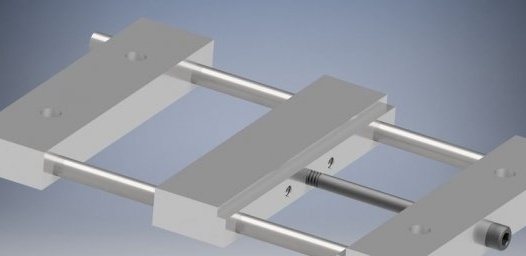

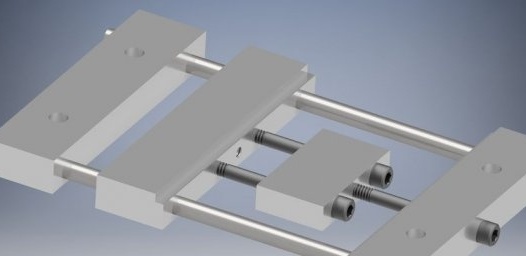

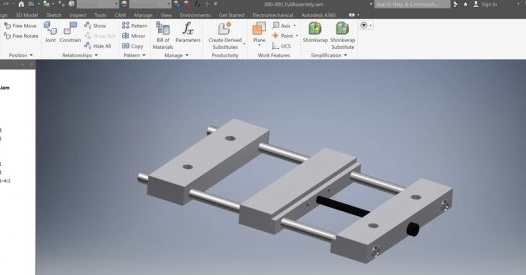

Step One: Project

First, the master, using a special program, made a vise project. The task was to make a low-profile vise with the possibility of mounting a milling machine on the table. As you can see, the vice consists of: a movable and fixed sponge, a fixed part and an additional clamp.

You can download the drawing file from the link below.

Step Two: Workpiece Processing

Cuts workpieces.

Grinds to the desired size.

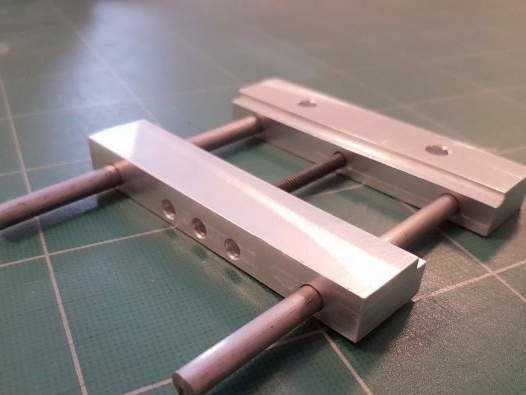

Step three: movable and fixed jaws

Next, the master processes the sponges. Marks and drills holes.

Cuts the thread.

Step Four: Milling

It processes workpieces with a milling cutter.

Step Five: Fixed Part

Now you need to process the part, which will be fixed motionless to the table. It also needs to drill holes for the rods.

Step Six: Extra Clamp

Makes an extra clip.

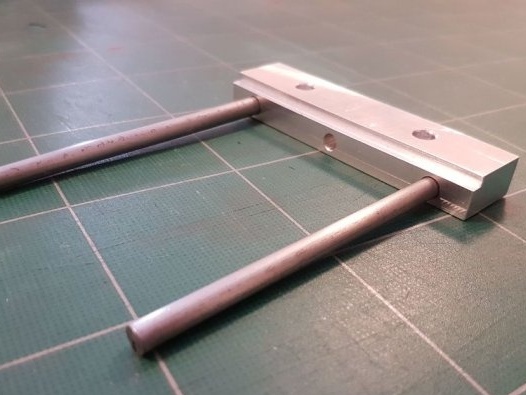

Seventh step: guide rods

At the ends of the rods, drills holes and cuts the thread.

Step Eight: Build

Now it remains to collect the vise.

And install on your desktop.