Tanto (短刀 短刀 tanto :, lit. “short sword”) - a dagger of a samurai. As Wikipedia tells us: the tanto has a one-sided, sometimes double-edged blade with a length of up to 30.3 cm and a total length of 30-50 cm with a handle. Tanto was used only as an auxiliary weapons (for finishing off, cutting off heads, hara-kiri, etc.) Tanto was used for the most part by samurai, but it was also worn by doctors and traders as self-defense weapons, women of high society. A tanto model with a wooden, plastic, and sometimes blunt metal blade is used for training in such martial arts as aikido, judo and karate.

It was such a knife that the Master decided to make.

Tools and materials:

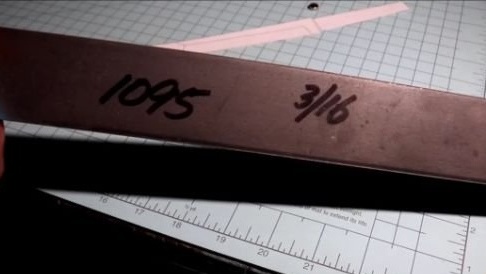

- Procurement of steel 1095;

- Brass billet;

-Bandsaw machine;

-Tape grinding machine;

-File;

-Vise;

-Sandpaper;

-Forge;

-Gas oven;

-Peanut butter;

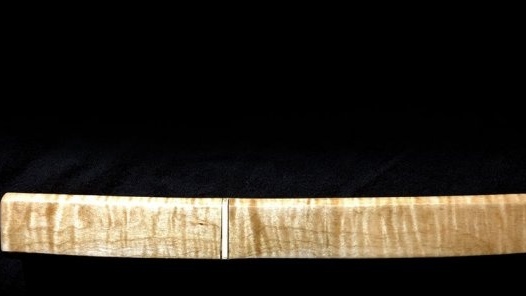

- Maple board;

-Hacksaw;

-Manual frezer;

-Knife;

-Marker;

-Epoxy adhesive;

-Shellac;

- Danish oil;

-Leather;

-Scissors;

-Magnet;

Step One: Harvesting

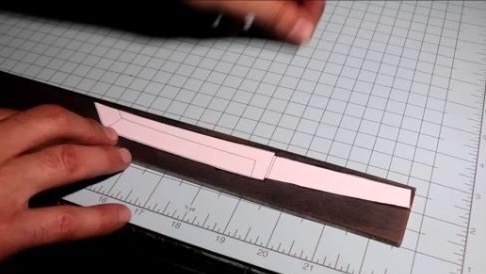

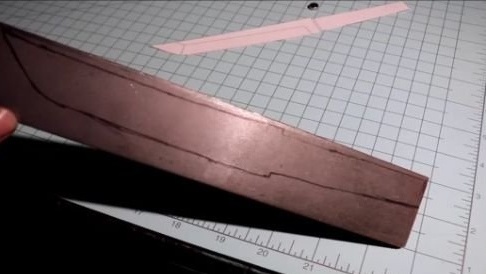

Draws a knife template on paper. Cut and transfer the template to a steel billet. Cuts according to the template on a band saw.

Grinds on a grinder and with a file.

Preliminarily displays descents, sharpening the blade.

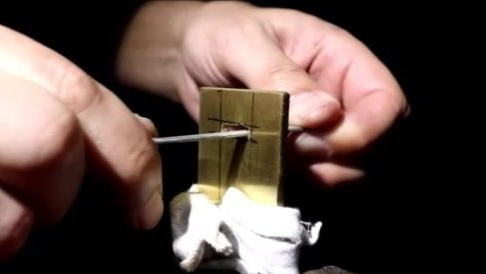

Step Two: Garda

Garda master makes of brass. Marks in width. Drills and cuts a rectangular hole. After the hole is ready, cuts off the guard from the plate.

Step Three: Heat Treatment

Before hardening, the blade is carefully ground and treated with acetone.

Further, the master places the knife in the hearth and heats up until it ceases to be magnetized. Having achieved this, the master dips the knife into peanut butter. After cooling, the master checks the quenching with a file. With proper hardening, the file will slide over the surface. If the file leaves a mark, then it is necessary to harden again.

Then the master again polishes the knife and washes with acetone.

After hardening, the knife is very fragile and must be let go. To do this, the master places the knife in the oven heated to 200 ° C for one hour.After an hour, the oven turns off and, together with the knife placed in it, cools naturally. When the knife cools down, the master grinds and polishes the blade.

Step Four: Pen

Next, the master began to make pens. Cut the maple bar into two slats. On the planks, the outline of the knife is drawn. Selects wood along the contour.

Cuts workpieces along the handle line. Checks fit.

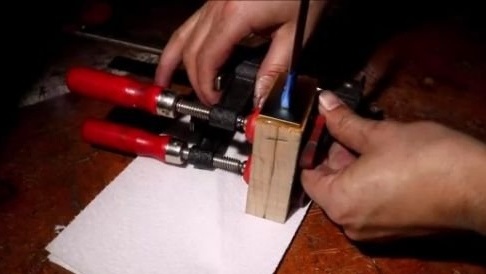

Then the master installs the guard, puts glue on the wooden blanks, glues the blanks by placing the knife handle between them.

Unfortunately, the master did not manage to perform the operation the first time, the footprint was increased. Then the master removed the handle blank and made a new one.

Step Five: the sheath

Making a sheath is similar to a handle, but there are a number of differences. Naturally, the blade does not need to be glued to the sheath. The selection for the blade is done more than for the handle, and two pieces of leather (on both sides) are pasted into the selection. The skin will prevent the knife from falling out of the scabbard.

Step Six: Handle and Sheath Processing

She inserts the knife into the sheath and, first, cuts the wood, and then processes it on a grinding machine, and manually, with sandpaper.

All wooden details of the knife are polished and the master applies several layers of Danish oil. It then polishes 600 with sandpaper and applies the last coat of oil. After some time, it puts shellac, polishes again, and again covers with shellac. Polishes with a cotton cloth.

All is ready.

The whole process of making a knife can be seen in the video.