In this article, the author of the YouTube channel "George Kosilov" will tell you how he made the simplest bottle cutter and made some beautiful glasses using it from ordinary bottles.

Such device can do in home conditions in a few minutes.

Materials

- Glass bottles

- Board or timber

- Chipboard sheet

- Wood screws

- Glass cutter.

Instruments, used by the author.

- Screwdriver

- Vise, hacksaw for wood

- Emery paper of the 80th grain, or higher.

- Square, ruler

- A bucket, a kettle.

Manufacturing process.

So, the master collected several bottles and found a glass cutter.

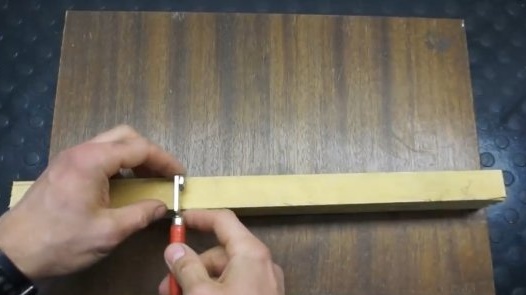

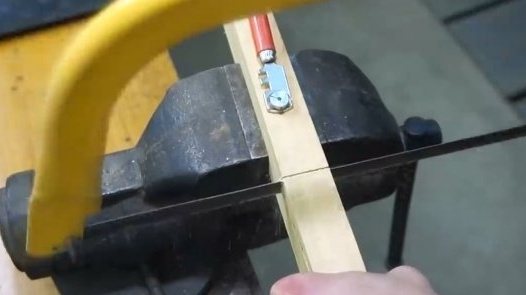

Then you need to fix the glass cutter in a wooden bar. To do this, the master cuts out a groove for a glass cutter in a bar.

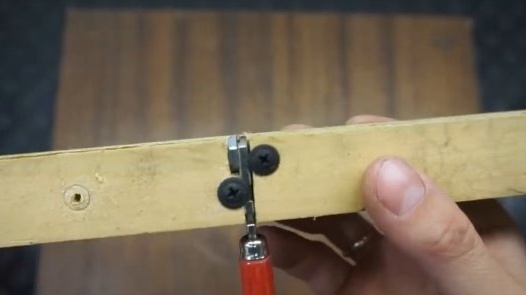

Sets the glass cutter, presses it with self-tapping screws with a wide hat.

Moreover, the glass-cutting wheel itself should protrude slightly beyond the edge of the bar.

As a basis, the master decided to use chipboard trim. Screwed a bar to him.

As an emphasis, you can use a short bar. The author aligns it with a square, and also screws it to the base.

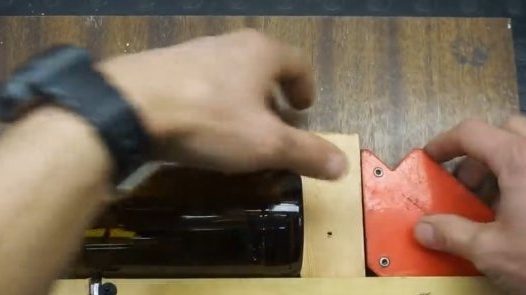

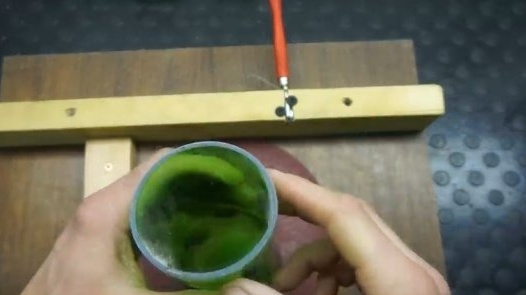

Firmly pressing the bottle against the glass-cutter wheel, he simply turned it. It turned out a very accurate ring.

I repeated the procedure with the rest of the bottles.

Boiled the kettle, and scored cold water in a bucket. First cooled the bottle, and then abruptly lowered it into boiling water. Here is such a smooth chip turned out.

And then he split the rest of the bottles. Moreover, the sequence does not play a role. You can first heat and then cool the place of cleavage - the effect is the same.

Here is a slide of cups. Yes, the necks also remain intact, they can also be used.

And the chips do come out very high quality.

And yet it is better to process them with sandpaper. The master used a skin of 80 grid, and believes that this is quite enough. On average, polishing one glass takes about 10 minutes.

It remains only to manually process the outer and inner edges.

To change the height of the resulting workpieces, it is enough to shift the emphasis to the side.

These glasses are obtained. You definitely can’t buy them in any store. And if the factory’s logo is on the bottle, it’s even more interesting.

Thanks to the author for the simple but useful technology for processing glass containers. In this way, cans can be cut.

All good mood, good luck, and interesting ideas!