In this article, Dania, the author of YouTube channel "SuperCrastan" will tell you how he made a meisel from a file.

Danya Kraster decided to continue the topic of expanding the cutting tool for a lathe. Firstly, it’s interesting to him now, and secondly, it will save a lot of money, and thirdly, with a clear conscience, I will be able to sharpen both finished products and parts for more complex projects. And knowing that the base, how to do all this yourself already exists.

Materials

- File

- Paste GOI

- Plywood

- A piece of leather.

Instruments, used by the author.

- Grinder

- Bulgarian

- Petal stripping disc

- Cutting disc

- Device for sharpening knives

- Grinding stones

- Lathe

- Clamp, vise.

Manufacturing process.

He bought several different files, one file costs about 300 rubles, that is, you can save on a cutter of this size 20 times, and make it for yourself.

Recently, he ordered a manual vise, to try what it is, and it turned out that this tool is very convenient for some purposes.

Presses a large flat file to the workbench and begins to remove the notch. You can, of course, not do this, but in this case, the cutter will cling to the skin. And in general, it is much more pleasant to hold smooth steelwork in a hand. Not to mention the fact that he can pull in the process of turning. In order to remove the notch, he chose the coarsest blade disc for the grinder, which he found on sale, namely the R35.

It is worth considering that circles have maximum speeds at which they can be used. This is especially true for circles with a brass brush. Once the author was tormented to pull out a brass wire poked into jeans. Therefore, if there is no speed adjustment on the grinder, then it is worth looking at their number before going to the store in circles. We clean the notch from the file on all sides, as much as necessary. Danya made the surface smooth, but decided not to grind to the end. Remained cool texture. An important point is not to get involved in the process, and take breaks so as not to heat the former file too much, and allow it to cool accordingly.

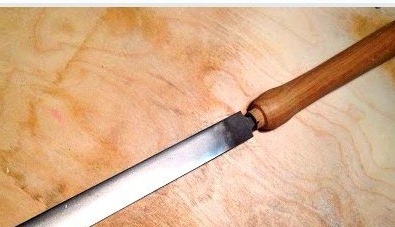

Next, note the line along which the end of the file will be cut. He will make a bevel at 45 degrees. It can be conveniently noted with the help of a square with an emphasis.Some types of squares have such an option as a bevel stop at 45 degrees. He also retreated some distance from the end where the blade narrows to get a thicker part.

It will be cut around for the grinder, again, it is worth taking breaks so as not to heat the workpiece. after it cuts off the edge aligns and cleans with a petal circle.

Now we need to focus on sharpening the chamfer of the cutter at the desired angle, namely 20 degrees. He sets the angle on a sawing machine, and drives a piece of thick plywood. The thickness of the base is needed for convenience in order to abut it in the table of the grinding machine.

In order to withstand the desired degree, the bevel is placed on the plane of the base of the blade, and leans against the stop. Presses with a manual vise, and yet very comfortable!

Then it begins to sharpen the chamfer, preventing overheating. He periodically dipped her in snow with ice. The same thing is repeated on the other hand. Meisel has double-sided sharpening, unlike a conventional chisel.

Next, you will need to sharpen manually. Firstly, because the grinding machine has a small circle radius, and it makes a concave lens. And secondly, because the graininess of this circle is not suitable for clean grinding.

For the final sharpening, he will use a tool for sharpening knives with aliexpress. Functionality that can be quickly made from a pair of clamps and studs. He begins to sharpen with the 120th stone, aligning the chamfers and making them flat. By the way, the clamp of this device did not master the thickness of the cutter, and I had to clamp it with a manual vise.

As soon as the bevels become even and flat, the stone changes, increasing the grain size. These Chinese stones clog quite quickly, so you have to clean them periodically. The last stone that is set is 1500 grit. The cutter of two sides processes it.

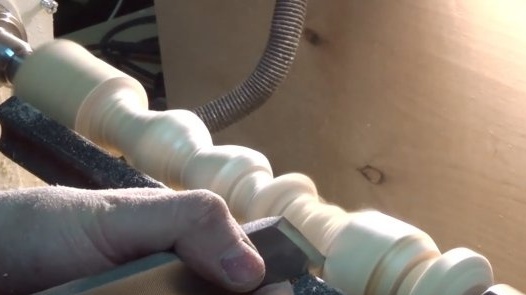

And at the end, Dania decided to go for a walk with a GOI paste spread on a piece of leather glued to plywood. He did this purely for show, without fanaticism. As a result, the author had a perfectly sharpened meisel, which even without a pen can be used without fear that he will get out of hand.

In the first photo, the look of this hellish instrument is more like a katana, but in fact it is quite convenient for them to work. The author believes that the resource of the tool will be enough for the rest of his life.

He also sharpened the reer normally, and now he cuts perfectly.

And now the trials of the Meisel itself.

Thanks to Dana Craster for a simple but very useful tool for working on a lathe!

All good mood, good luck, and interesting ideas!