It will be about the "standby" computer almost constantly working. Often around the clock. Work, browse the Internet, watch movies or cartoons, leave for the night to download something big to use up the night part of the available traffic. The described refinement on the one hand (water cooling) allowed the system unit to become much less noisy and annoying, on the other hand (case), the congenital malformations of the system unit case were eliminated. Oh, it was just a poem! The start button on the false panels had a significant area and great depth. The slightest skew jammed her in a drowned position and the poor thing had to be picked out with a table knife. The design of the windows for optical drives was so intricate that it would be amazing if it worked as it should. The buttons were located on the side of the drive and had several plastic levers inside. They had to press the standard button “ejecting” the tray with the disk. These buttons did not come off the collective and also jammed to death in the pressed position, and even the table knife was powerless here. Armed with a flashlight and opening the false door of the drive, press the button from the inside.

What was required to work.

A set of medium-sized bench tools, a set of tools and soldering accessories (structural, electrical). Tester, building hair dryer, jewelry jigsaw, small gas burner, screwdriver.

Galvanized steel 0.5 mm, silicone hoses, sheet brass of different thicknesses for heat exchangers, a circulation pump for an aquarium or a desktop fountain, a kit for indicating the flow of the coolant and measuring its temperature, wires, fasteners, small things.

Front panel It was maximally simplified. All the tinsel with pleasure was torn off, the remaining perforated galvanized grate was considered quite a sort of industrial design. Especially when you consider the future table-top deployment of the system unit, where it will not be too callous eyes.

In order for the sockets and the drive to fall into place, I had to work with a file, a fair amount of fuss was also required by the socket with additional USB ports. Instead of the flimsy regular start button, which also had no attachment other than to the false panel, a harsh domestic KM-1 was installed. The LEDs for turning on and accessing the hard drive are pulled from the inside by nylon straps for mounting. Previously, the plastic cases of the LEDs were slightly sanded to expand the radiation pattern. So that they were better visible on the side.

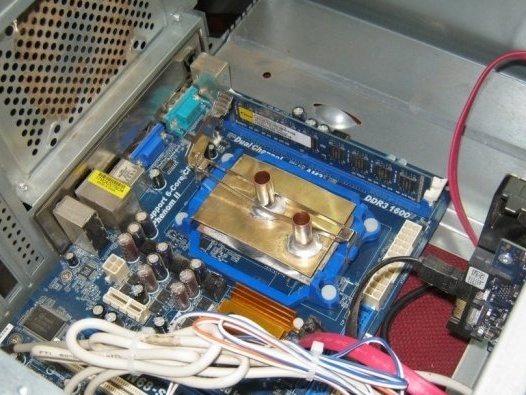

Water cooling - without venting heat to outside radiators with blowing. Instead of them - a significant volume of a container of water. Its wall area is enough for passive cooling. In general, the cooling scheme looks like this.

Heat exchangers mounted on hot chips made on their own easy soldering technology. Involved regular mounting radiators.

Also, a similar heat exchanger is made and installed on a large chip of the north bridge. Separately, I had to tinker with the power supply, it was also redone for water cooling. He left only a small fan for it, turned on, at a voltage of 5 V. It rotates completely silently, the hard drive motor is working louder. The task of the fan is to blow warm air out of the power supply box, otherwise it stagnates there, heating the components and reducing their life and reliability of the unit as a whole.

For field tests, a simplified cooling system was assembled, which worked for about two months. The capacity-cooler of the system unit was a standard 3 l glass jar. When the computer was working round-the-clock and the room temperature was 22 ... 24 ° C, the temperature sensors built into the chips showed no higher than 40 ° C. The coolant temperature was slightly lower. In general, the cooling system, even with such extreme simplicity and cheapness, is quite functional and has shown good results.

The almost complete absence of noisy fan cooling greatly reduced the noise of the working computer as a whole. The main sounds were the quiet hum of the water pump motor and, most loudly, the hard drive. The sounds of his life became perfectly audible, he periodically creaks and squeaks, the motor spinning the disk evenly buzzes. Vibro decoupling the HDD from the tin case on the advice of a colleague Pronin managed to reduce its noise a little. Here, the hard drive was removed from the regular compartment and inverted laid at the bottom of the system unit. It was possible to place it relatively freely at the bottom, carefully forming the wires of the system unit into bundles and putting excess in free compartments for a DVD drive and hard drives. Four soft high legs were cast from silicone sealant on the Winchester’s lid. After the sealant solidified, they were scissors aligned in height.

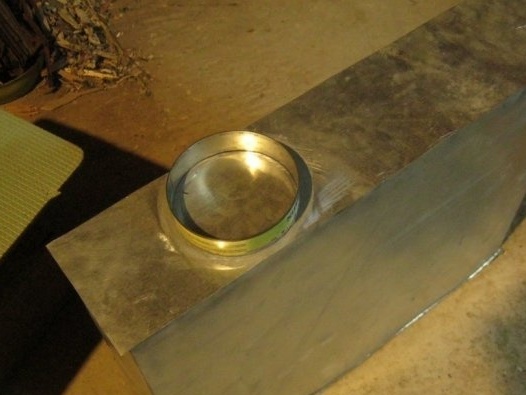

Heat exchanger tank was welded from galvanized steel roofing. Its flat design was dictated by the placement on a wooden wall in the manner of a steam heating radiator. In addition, such a shape is easy to make, all the details of the construction are rectangular - they are easy to make by cutting out with ordinary scissors for metal, there is not much waste after manufacturing.

Tank capacity made a little redundant, it was an accident, the capacity of three or four test three-liter cans will work perfectly. That is 10 ... 12 liters. The width of the container is such that it can fit in by hand. This may be useful in hypothetical emergency or preventive maintenance. In addition, the initial installation involves tinkering with putting on hoses on fittings. To prevent "inflating" the flat walls of a relatively large area, in the middle from the inside, the walls are connected by a "spacer".

The tank was made of four main parts - the main part, the bottom, the lid and the neck. The main part is bent out of a sweep strip. Additionally, a 25 mm wide petal allowance was made to solder the lap edges. It was soldered with an ordinary lead PIC (cheaper), warming the place of soldering with a small flame of a gas burner.The flux used special for the brazing of copper water pipes. This is a gray paste with the addition of the smallest particles of solder, designed for tin-copper solder flux, but also works well with lead. You can try other inorganic fluxes, such as soldering acid (zinc chloride). The main problem during soldering is warpage of the heated part of the sheet, the phenomenon can be reduced by frequent technological fastening of the surfaces before soldering, work with a small flame or fast work with a powerful, well-heated soldering iron. Flux (acidic) should be washed immediately after soldering with warm water.

The neck of the tank should be wide enough (hand) and closed quite tightly to prevent evaporation of the coolant. For example, about one and a half glasses of water evaporated a week from an open can. We managed to make a suitable tin neck with a plastic lid from cutting the cans from dry baby food. The top of the can with a height of about 20 mm is trimmed, the edge is aligned, cleaned of paint and soldered to the tank cap. The hole itself, made from the inside of the soldered neck - a number of holes were drilled along the entire diameter of the future opening, the lintels between the holes were sawn through the side of the flat file, the sharp edges were lined with a semicircular file.

Suspension ears and two nozzles for connection to the cooling system are also made and installed on the tank. The tank is washed from flux residues, checked for leaks, dried, degreased with gasoline and painted with two layers of gray enamel. After complete drying, installed in the place of service. The bottom of the tank rests on a small stand-block.

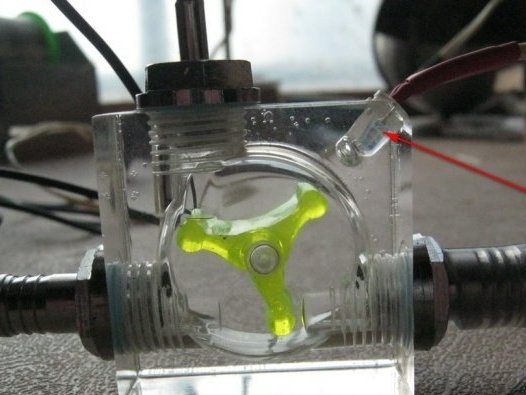

For convenient indication of the operation of the cooling system, a transparent water turntable with a remote indicator of the coolant temperature is installed. A transparent unit with a temperature sensor is installed at the hottest point in the flow - at the outlet of the system unit. The pinwheel is made of yellow plastic that is highly luminous in ultraviolet (UV). A backlight is introduced into the transparent block - a blind hole is drilled on its edge, into which a UV LED is glued with UV glue.

The LED is powered from the standard +5 V through a current-limiting resistor 360 ... 390 Ohms. The LED is connected with a standard four-pin plug taken from a faulty hard drive.

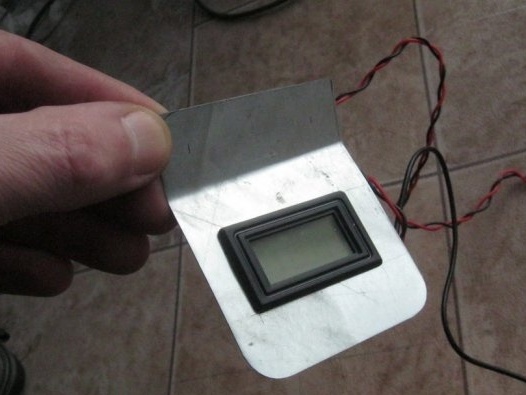

The remote module for displaying temperature was placed in a convenient place on the system unit on a small panel cut out of galvanized steel. The opening for the installation of the device and rounded corners are cut by a favorite tool - a jewelry jigsaw. The panel is fixed with two M3 screws.

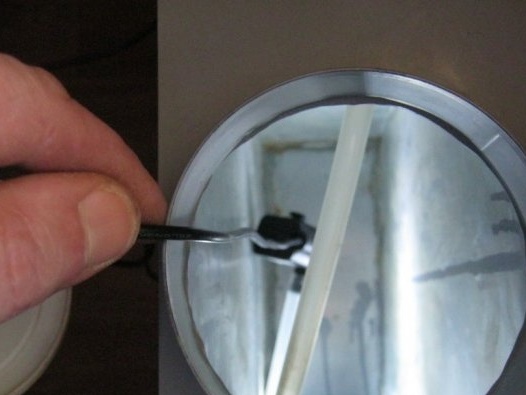

A transparent unit with a turntable was installed on the side surface of the system unit using nylon straps. For them, I had to drill holes near the motherboard. In order not to remove it, under the place of drilling I put a piece of tin. This did not allow the board to be damaged by a drill and prevented metal sawdust from getting inside.

The system unit is installed on a special shelf under the table next to the tank on the wall. Inside the tank, two pieces of silicone hose are dressed on the nozzles - one loosely hanging for draining, the second is more authentic, connected to the submersible pump near the bottom of the tank.

The standard USB connector of the pump is cut off, the power cord is threaded into the hole punctured in the soft plastic cover of the tank and is equipped with an “internal” power connector, like the LED from the old unsuitable “hard drive”. This will allow you not to occupy the extra USB connector on the outside, making an important connection more reliable.

All electrical and hydraulic connections are made, the tank is almost completely filled with water. Order, you can try.

Conclusions, ways to improve.

As a result of the work, a convenient and very quiet stationary personal computer was obtained for long-term or round-the-clock operation. All “hot” components of the system unit are cooled properly - the maximum temperature of the components in the full configuration decreased to 30 ... 35 ° C, the coolant is heated to a temperature 2 ... 3 degrees above room temperature. The noise level is completely incompatible with regular air “fan” cooling.If sitting at the workplace you can still hear a small buzz of the pump and the motor of the hard drive, then three steps from the table it is very difficult to distinguish these sounds in ordinary village silence.

The performance of the cooling system is well and conveniently controlled.

The whole system is very cheap, especially if you use a container from a hardware store instead of a home-made one and abandon the purchased turntable with a thermometer.

However, you can specify several relatively simple ways to improve the device.

As a heat carrier it is worth using an aqueous solution of an antiseptic, this will avoid the buildup of simple algae in the water. An antiseptic should be safe for humans (likely evaporation), cheap and common (general concept), not be aggressive to parts of the water supply. Cheap pharmacy alcohol solutions are considered as likely candidates for adding to water.

Instead of a temperature indicator, you can use a similar indicator with a water flow meter. This will provide more data for analysis, the indicator of such a device looks more advanced.

Inexpensive pump made in China a little, but buzzing. This noise, as they said, is quieter than the noise of the HDD motor, but this is a reserve for maintaining silence - you can try to use water pumps more expensive.

The way is simple, but expensive - instead of a buzzing mechanical HDD, use silent "solid state".

Babay Mazay, March 2019