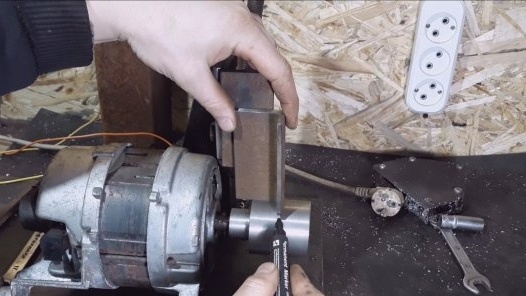

Collector engine, power 400W. Turnovers are adjusted to handle various materials. As a regulator, a home-made unit made on Arduino.

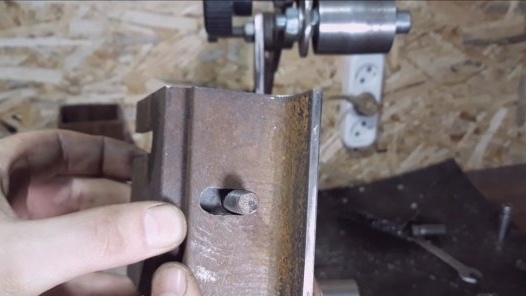

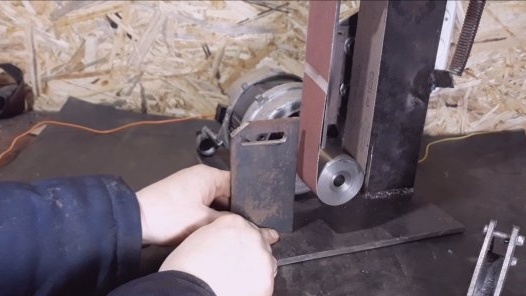

Let's get started. A 7 mm thick sheet of iron was taken for the base. The size of the plate was 250 by 300 mm. From the same piece we cut a vertical stand and weld as in the picture. Also, do not forget about the scarf for stiffening. There are no special sizes, since everything was done for a specific engine. You, too, focus on what you have. And I think you’ll understand the general layout. A drive roller with a diameter of 55 mm was also ordered. It is mounted on the motor shaft and locked with an M6 bolt.

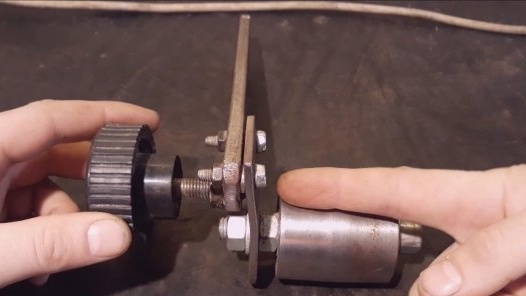

The upper node serves to adjust and hold the tape in the working position. It consists of two plates perpendicularly twisted together. a roller is attached to one bolt, a nut is welded to the other with an adjusting screw screwed in.

When the bolt is screwed in, the plate with the roller bends to one side, and when twisted to the other. This is the adjustment of the tape from displacement. Well, the rollers themselves should be in the same plane. Also, the upper roller is made in the form of a barrel. This allows you to hold the tape when working in one position. This assembly is bolted to the vertical stand. Between the plates there is a thrust bearing from the front strut of a Ford car. This connection must be movable, but without backlash. It serves to tension the tape. A spring is tensioned on the reverse side.

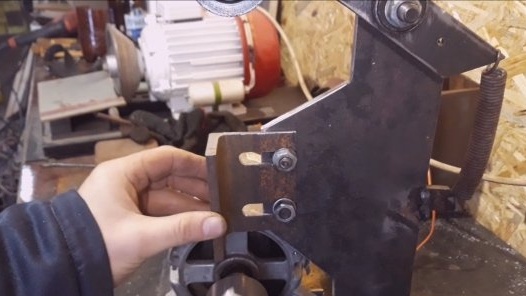

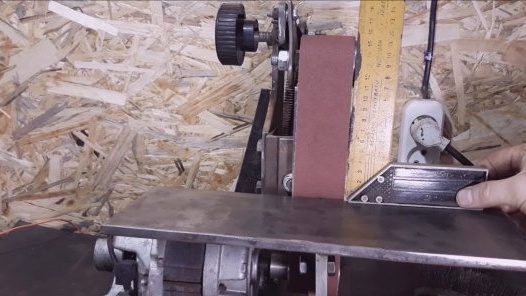

Now, from a channel cut in half, I made a bracket for the pressure pad. It made grooves for adjustment. The clamping pad is welded to the second piece. It is screwed to the first trim on a bolted connection for the ability to adjust the position of the site.

The little table for work is cut out of a 10mm sheet. Size about 150 by 300mm. A bracket with a hole is welded to the base and a kerchief is added.The same plate is welded to the table. The hole is made in the form of a slot. This allows you to adjust the table. It can be moved closer or further relative to the tape, as well as change the angle of inclination. It is convenient when sharpening various tools. During assembly, the table is set perpendicular to the side of the tape.

The entire structure was disassembled and painted for a more aesthetic look.

What can be said about the engine, then its power is enough. At a speed of 6000 are set on the regulator. With this diameter of the drive roller and revolutions, the belt speed is decent, and together with the adjustment they allow to process various materials. The engine must be closed to prevent metal dust.

Here's a little assistant assistant appeared in my the garage. He stopped using emery at all. Here you can put a tape of different grit. Well suited for sharpening tools and drills. And also it perfectly displays downhills on knives.

At the end of the video is a detailed description of the assembly of the grinder.

Thanks for attention.