Hello everyone, in this instruction we will look at how to make a simple furnace for melting aluminum from a gas cylinder. Such a furnace works on gas, its design is very simple and cheap. Such homemade It will be useful if you want to cast various parts for your projects from aluminum or other metals with a similar or lower melting point. Homemade also includes the process of making the simplest crucible for this furnace. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- gas cylinder (from the author from under freon);

- heat-resistant insulator or stove clay;

- two pieces of pipe (for incoming and outgoing);

- a piece of thick-walled pipe, as well as a round log and a nut for the crucible;

- gas-burner.

Tool List:

- ;

- ;

- miter saw (optional);

- drill with crowns;

- marker.

Furnace manufacturing process:

Step one. We cut the balloon

First of all, cut the balloon, we need to cut off the upper part. Before cutting, the crane must be unscrewed and the contents released. If a flammable gas cylinder was used, it must be washed or filled with water before cutting, otherwise the cylinder may explode with all the consequences.

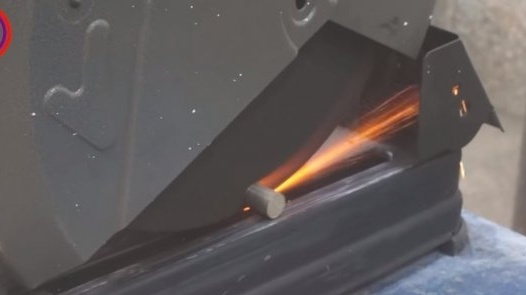

We need to cut the neck, we don’t need to throw it out, a lid will be made of it. The author draws a line with a belt, and then cuts along the line with a grinder.

The edges of the cut cylinder must be sanded with a petal nozzle so as not to cut your hands on the sharp edges of the metal.

Step Two Pipes

Next, you need to weld two pipes into the furnace body, one will be the input, and the other the output, which is the lid. We drill a hole in the bottom of the cylinder with a crown and install a piece of steel pipe, weld it to the cylinder. We will insert a gas burner into this pipe. A similar piece of pipe is welded to the furnace lid.

Step Three Thermal insulation

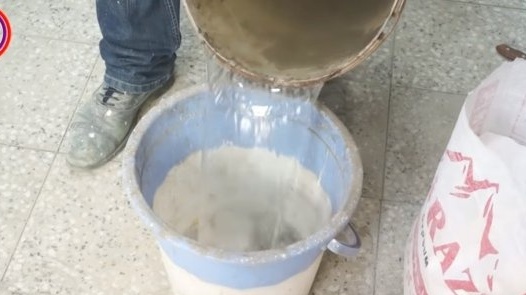

Next, you need to equip the insulation in the furnace, otherwise a lot of heat will be lost during operation, and the furnace will quickly burn out.Here we need oven clay or another heat-resistant solution. To begin with, we make a cylinder of paper, linoleum and other construction waste, install it in the center of the furnace. Well, then we dilute the solution and pour it into the furnace around the cylinder, and when the solution hardens, the cylinder can be pulled out. Even if something is not pulled out, it will burn when the furnace is first started.

As for the lid, we also plaster it from the inside. To prevent the coating from falling off when the furnace is warming up, it is better to weld bolts, curved plates or other parts to which the coating can hold onto the inside of the lid.

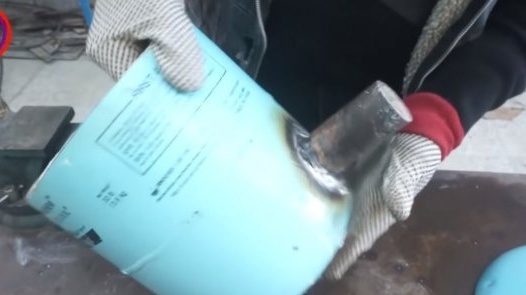

Step Four Crucible making

We make a crucible in which we will melt aluminum. Here we need a piece of a thick-walled pipe, to it we weld the bottom of a thick sheet metal. Everything must be airtight, otherwise aluminum may leak into the furnace during operation.

It remains to make a handle for the crucible, it is removable and assembled from the round timber, and for fastening the handle the author welded two pieces of the round timber to the crucible. A nut is welded at the bottom of the crucible, you can cling to it to tilt the crucible to pour the metal. It is also necessary to make a nose for the crucible, cut two triangles and weld them on the crucible, having previously cut a triangular piece of metal from the crucible.

Step Five Test

The homemade product is ready, you can start the furnace, light the burner and insert it into the furnace. First, we melt the first small piece of aluminum, covering the stove with a lid. Further, when the first part of the aluminum has already melted, other pieces can also be lowered into it, the melting will go much faster, and the furnace will already be covered and not necessary, the metal will melt already from the hot crucible and the available liquid aluminum. Towards the end, the author is already melting rather massive aluminum blanks.

Having poured hot metal into a tin can, the author cut it and pulled out a solid and beautiful piece of metal. When pouring aluminum into cans, be careful, the metal can easily burn out and red-hot aluminum will flow to your feet.

That's all, the homemade product is ready, I hope you liked the project. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!