A compact Chinese-made fire alarm is very good - it responds to two different “irritants” associated with a fire (CO and smoke), the presence detector (and concentration meter) of carbon monoxide is also very useful in a room with stove heating. The alarm system is compact, not expensive. As usual, the continuation of virtues is her vices. Both result from compactness and low-voltage battery power, this is the low volume of a standard siren (simple piezo-emitter), the combination of two sensors in one housing requiring different installation (smoke - on the ceiling, CO - at the chest level of the "operator").

The first attempt at improvement was made in the direction of increasing the volume (the alarm was installed in a separate workshop). The piezo emitter is brought out under the roof overhang, equipped with a horn. The volume of the alarm increased, it was heard outside, from the house. Nevertheless, there was still no qualitative increase. From the house nearby, during the daytime fuss, the sound of a siren could not be noticed.

Description of the design.

The second attempt to improve the alarm is more thorough. Here, the siren on the piezoelectric radiator is replaced by dynamic heads (taken out) with a simple amplifier, a power supply is made instead of galvanic cells, and smoke and CO sensors are spaced. All this allowed to use the potential of the device more fully.

The block diagram of the upgraded device is as follows:

Power supply +5 V.

With stabilized output voltage (significant fluctuations in the network). The stabilizer is assembled on the basis of the KR142EN5A chip and has no features.

For the K142EN5A microcircuit, the capacitance of the input capacitor C1 should be at least 2.2 μF for ceramic or tantalum oxide and at least 10 μF for aluminum oxide capacitors, and the output capacitor C2 at least 1 and 10 μF, respectively. The input capacitor can be played by a smoothing filter capacitor if it is located no further than 70 mm from the microcircuit.

The KR142EN5A microcircuit can be replaced by an imported 7805 and its analogues. The maximum input voltage for KREN5A is 15 V.

Power Amplifier

The simplest single-cycle transformer. Assembled on two (one composite) transistors. The amplifier has its own rectifier not connected to the power supply of the digital part of the device.

The alternating voltage for the amplifier rectifier is taken from the remaining free windings of the transformer TPP-215 used to power the digital part. A protective diode in a composite transistor, here you can apply somewhat less powerful. The matching transformer is taken from a transistor radio. The lilac highlighted circuit can be replaced with one composite transistor KT829A.

It is worth saying that the amplifier circuit is not quite optimal in this application - it was originally intended to work on a piezo emitter (the matching transformer was turned on the other way round), but it was not possible to achieve a sufficiently high volume and the experiments continued with dynamic heads. In the design of UMZCH “from scratch” it is better to use a push-pull amplifier or UMZCH on an inexpensive specialized microcircuit with a power of several watts.

What was needed for the manufacture.

Tool kit for radio installation, multimeter. A set of medium-sized bench tools, a screwdriver, a building hair dryer.

with Ali Express, radio elements, installation and network wire, thermotubes, fasteners. Materials and tools for the manufacture of printed circuit boards.

Practice.

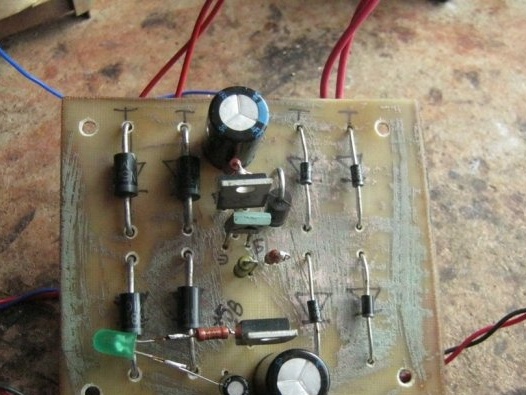

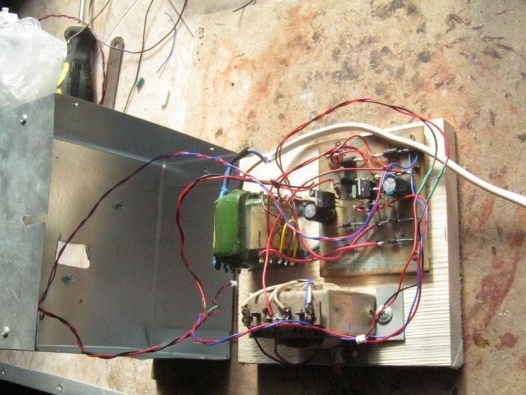

The device was assembled on a printed circuit board - there are both rectifiers, a stabilizer +5 V, UMZCH. The circuit board is designed in Sprint-Layout 5.0 and transferred to foil fiberglass using photoresist.

Transistors and the stabilizer microcircuit work without radiators, their cases are not completely heated. The device also includes two indicators of the supply voltage (digital part and amplifier), which are a chain of LEDs and a current-limiting resistor (not shown in the diagrams).

Above, a photo of the layout of the device with a piezo emitter, below - with dynamic heads. Here, a pair of 2GD-40 oval speakers connected in series, with a 4 ohm voice coil impedance (front panel from an old low-end reel tape recorder) are used.

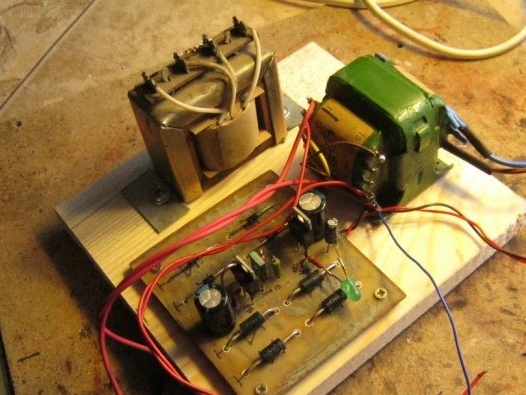

After it was possible to achieve good operation of the amplifier on the layout, I began to assemble the device in the case. It is a wooden base on which new additional units are mounted. The device is closed by a tin cover on which the factory alarm is fixed. The design used wiring for the external "attic" speakers from the previous upgrade.

A board is fixed on a piece of a thin planed pine plank with four thin screws. Two racks of linoleum placed under each screw were used as racks. A standard power transformer is secured with four M3 screws passed through the base, the matching transformer had four tabs for installation by “twisting” in a thin metal base. Its reliable fastening was made of two pieces of thin metal with holes for screws. They pressed the bent petals of the transformer holder to the wooden base.

After installing the components of the device, the lengths of the wires were clarified and all electrical connections were restored.

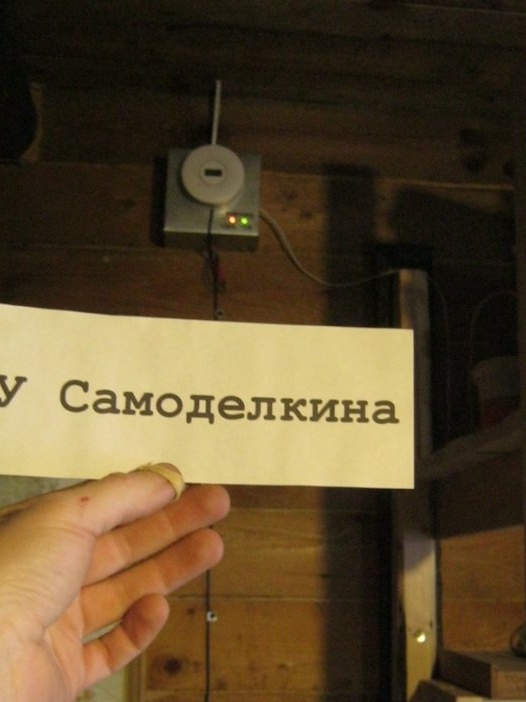

With three short cogs with a complete gentleman's set (washer-nut-grover), a plastic removable sole for the fire alarm was mounted on a tin casing. A wood jigsaw, previously an aperture for connecting wires was sawn in it, a small angle grinder a similar hole was made on tin.

Two LEDs for indicating power are fixed in the holes on the inside of the device’s case, a thick tinned copper wire passed between the legs of the LEDs and soldered to the edges of the case.

To output the power cord and wires for connecting speakers, special grooves are made in the casing. The wires are fixed to the base with a tin bracket, a knot is fastened on the power cord that does not crawl into the hole.

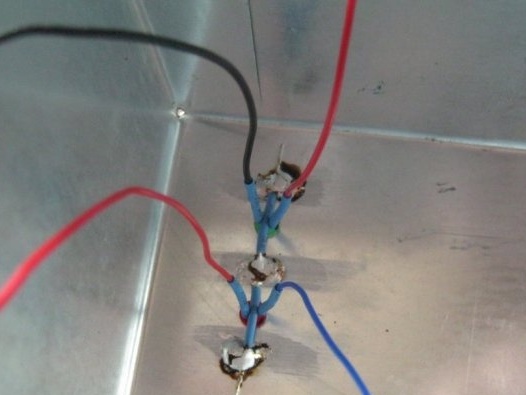

A fuse with leads is soldered between one of the terminals of the power cord and the tab of the power transformer. After installation, the fuse is thermotube insulated.

The rule of good form is the signature of the appointment of indicators. Here, for simplicity, the signatures are made with a durable varnish marker.

In the photo above, the arrow shows the remote CO sensor. For testing.Below - he is in a protective tin casing on the wall. The wire is fixed on a wooden wall in several places with tin clamps. The length of the "spacing" is about 1 meter.

A panel with two speakers is installed in the attic of the workshop near the pediment. It is attached with soft wire to the wooden elements of the roof.

Conclusions, ways to improve.

As a result of the work, a functional device of a higher class was obtained than the factory one, which served as the basis. The volume of the amplifier with speakers is enough. However, there are several possible ways to improve the design.

The amplifier is better to use push-pull or on a special chip.

It is better to equip the speaker system with a body (shield) for separating the diffuser vibrations “forward” and “backward”. The effectiveness of the speakers will increase. This can be a simple tight box of relatively large volume or embedding dynamic heads into the plywood sheathing of the pediment. In any case, the heads should be protected from snow and rain.

Compact fire alarm manual

Application.

Device circuit board.

Babay Mazay, March 2019