In this article, Andrey, the author of the Stroykhak YouTube channel, will tell you about some useful tips.

So, the next selection of simple, but very useful tips for masters and amateurs.

Materials

- Plywood

- Expanded polystyrene

- chain

- PVA glue

- Elastic.

Instruments, used by the author.

- Dental floss

-

- clamps

- Vibratory grinding machine

- Grinder

- A pencil.

Manufacturing process.

The first tip is how you can control the process of grinding wood? How to understand where and how much you have already polished? After all, if you do not control this process, the consequences can be very disastrous. For example, you can grind the edge of the bar, and violate the geometry of the workpiece.

Or even worse, sand through the veneer - a thin layer of wood glued to the workpiece. In this case, nothing can be fixed - you have to re-paste everything again.

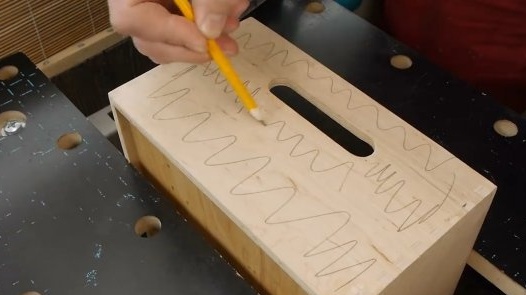

How to protect yourself from such cases? With a very simple action, or rather a simple pencil. We take a pencil and outline your entire surface, which you will grind.

Now you can clearly see where you have already polished, and where not yet. And don't make a mistake anymore - a simple pencil for a simple solution.

A hand saw for metal is a good thing, unless of course there is a grinder.

But the question arises - where to store all this bunch of paintings for her, and so that she doesn’t constantly look for them in the drawers?

In order to keep them handy all the time, spend a couple of pieces of insulation tape.

Now the canvases will always be in your sight, will not be lost, and at the same time will not interfere with your work.

It happens that a situation arises when an urgent need to finish work, and the technique fails.

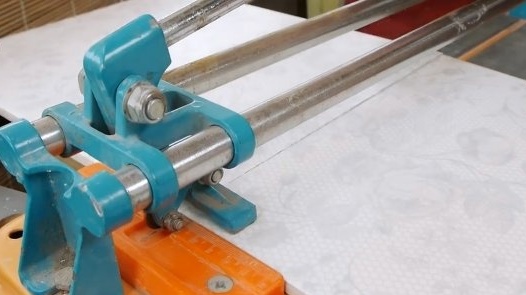

In this case, you can make a hole in the tile with a pneumatic gun. A plastic bag must be placed between the tile and the barrel.

And then cut the hole with a jigsaw.

Let's move on to the next tip. When repairing wooden products, it is convenient, of course, to stick a piece that has fallen off completely. Then we just coat it with glue, and press it with a clamp. But how can glue be launched into the very depths of a thin rift where nothing can be reached?

Use a thread for brushing your teeth! Glue with glue where possible, and then start working with thread. See how deep it goes due to its shape.It turns out to drive the glue to the very end of the fault, smearing the most inaccessible places.

Now you can stick everything else.

Excess glue can very easily be removed with wood chips or wood dust. It absorbs glue very well.

The next tip is useful for auto mechanics. If you put the rubber on the socket wrench, then when working in hard to reach places, inserting a bolt on the rubber, you will not lose it. Due to the friction force, it will hold very tightly.

If you have safety glasses with a good old shockproof glass, then, of course, they are not afraid of anything. They can be put anywhere and stored with other tools.

But if your goggles are made of modern polycarbonate, then they should be preserved and not thrown anywhere. The simplest and cheapest case for such glasses is a regular thick sock. In such a package, glasses can be safely put in a tool box, or hung in a workshop.

For radius marking, an ordinary chain may come in handy. In skillful hands, she turns into a miracle compass with a small step. It can be used in various situations.

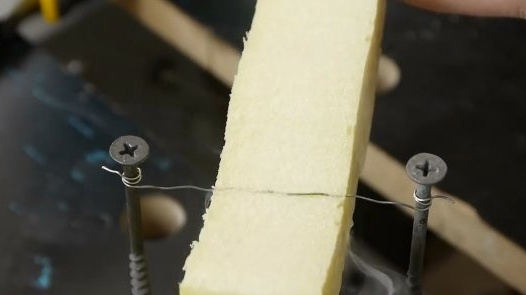

The last advice was a real discovery for the author. Figured cutting of polystyrene is done either with a hot nichrome wire, and poisonous fumes are obtained.

Or a jigsaw, and gets a bunch of dust sticking to everything. How to get rid of both at the same time? It will be especially useful to people who work with polystyrene foam at home.

You just need to grind all the teeth on an old nail file.

Can such a nail file be cut without a single tooth? Surprisingly, it cuts! It cuts the same way as with the teeth and practically without dust. Unless a little slower. Only single melted pieces remain.

Thanks to the author for simple but useful tips for the home and workshop!

All good mood, good luck, and interesting ideas!