Hello dear aircraft modellers.

The holiday came on February 23 - the day of the Soviet army and navy!

Usually on this day I start a project or build a new aircraft model. It has become my tradition. So this time, I started a new project AlIS - 4 "Fang".

The project provides for the creation of two aircraft models for the Victory Day - May 9!

So far I want to talk a little about the first model.

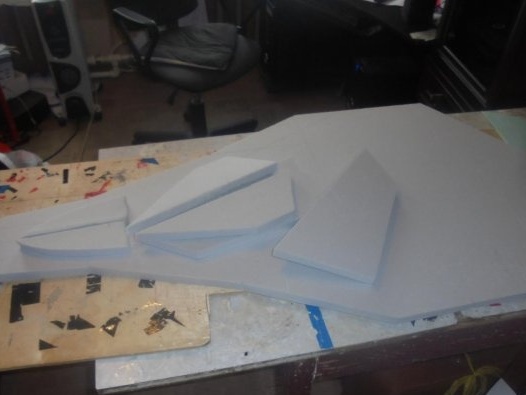

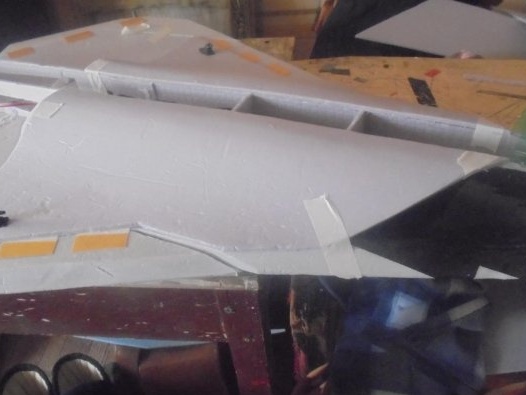

The abbreviation AlIS is the abbreviated surnames Aleksandrov and Sudakov. This is the fourth aircraft model in this series. In principle, there is nothing new in this model. Model It is created according to a simplified scheme and its basis is a sheet of insulation "Penoplex", 20 mm thick.

The main dimensions of the model

Length - 1450 mm.

Span - 800 mm.

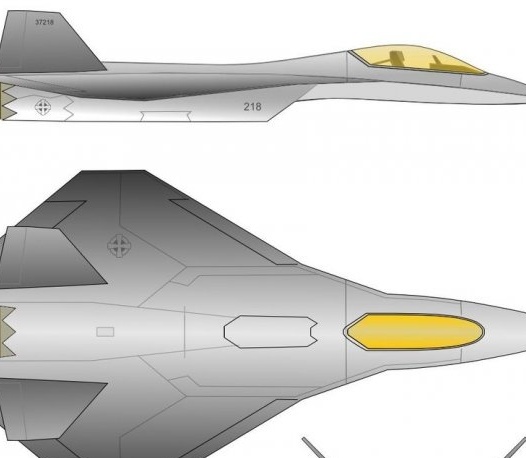

According to its outlines, the model resembles a drawing of artists of the PAK FA Su-T 50 aircraft that has not yet been created.

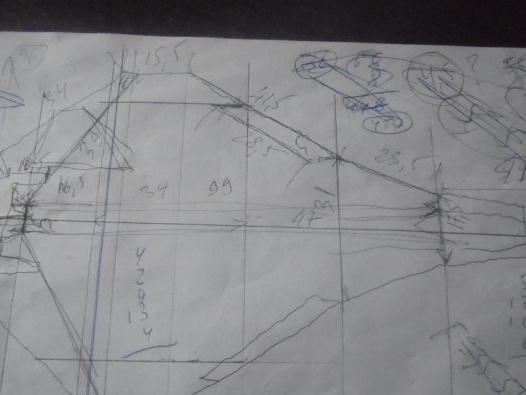

I even wanted to make the same slats on the model, but in the process, I came to the conclusion that these rudders are inappropriate on such a model. He began the work by copying the outline of this figure directly onto a sheet A 4 from a computer monitor, choosing a scale and putting down the dimensions.

Almost my wishes - to fit the wing on one sheet of Penoplex insulation were fulfilled. The length of the model was added by ailerons and PB.

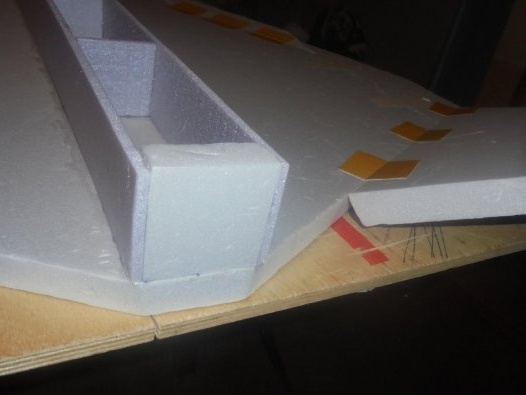

As usual, he began further work with the creation of the bow of the fuselage and the cockpit. I pasted the internal vertical partitions running along the entire length of the fuselage, from which, on both sides of the wing, the outer skin of the model is glued. Due to the outer casing, air ducts were formed on both sides of the cab. As a lantern, for a cabin I cut a piece of a plastic bottle. The pilot's figure was cut out of cardboard and painted with felt-tip pens.

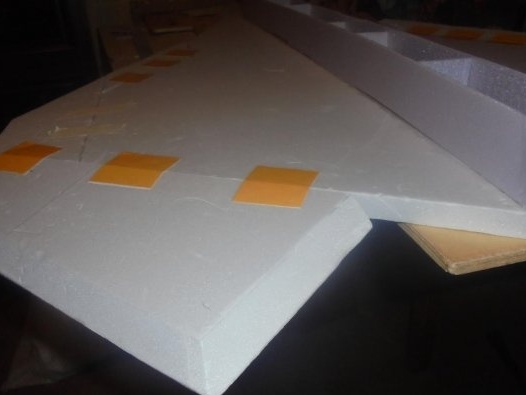

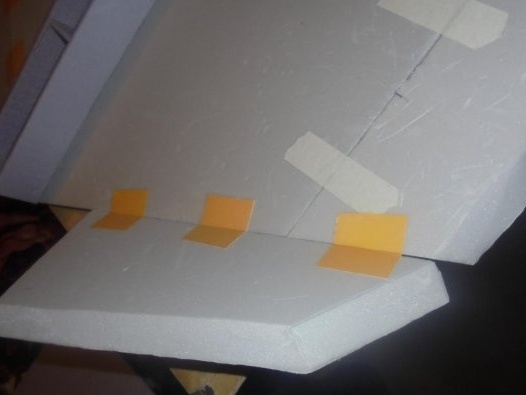

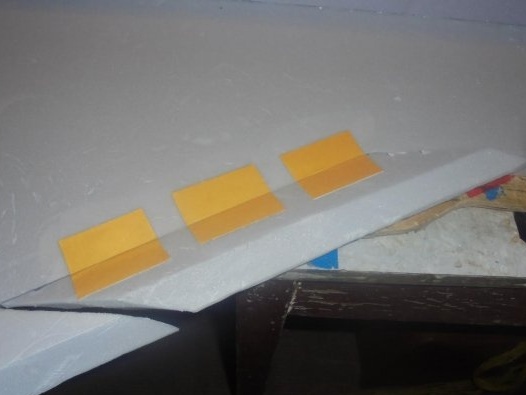

He began work on the hinged rudders. All steering surfaces hung on a double-sided tape with inserted between two layers of pieces of plastic from the paper folder. The hinges are very durable and flexible.

On the elevator mounted the steering surfaces of the direction. The result was a kind of all-aspect OBT.

Mounted servos, connected traction.

This is how this control node works.

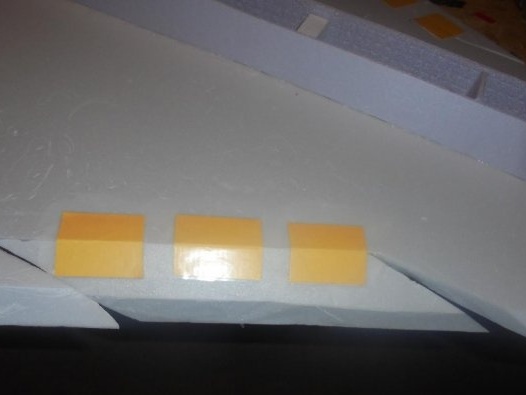

Without waiting for the end of the work, I spend the local pasting of the model with colored tape. Design work is underway.Made inscriptions, glued stars and St. George ribbon.

I cut the blanks for keels, tried on, fitted them in place. I will paste after installing the ailerons control servos. I really want to put BANO, but the wiring will have to be done on top of the outer skin of the wing.

On the underside of the wing made an additional hole, for more air to the impeller.

In principle, the air entering through the duct is quite enough, but in order not to overload the impeller, I decided to play it safe.

I built a tube - an air duct on the carbon body of the impeller, ending in a narrowing within 4-5 degrees. The total length of the tube is 190 mm. The impeller diameter is 64 mm. Made the input "lip" of the substrate. The outlet on the tube is 60 mm.

On the underside of the wing, to install the chassis, glued pieces of fiberboard (hardboard) 45 X45 mm. Chassis racks are made of aluminum plates, lightweight wheels, purchased.

The total weight of the model turned out to be 1100 g. I changed the picture a little. Reduced the order ribbon.

That's probably all!

So the model looks on the last snow of the outgoing winter.

Selfie for memory.

Tests will be conducted May 9 on Victory Day.