Walnut kernels are a delicious and healthy product. But chopping nuts is a tedious and tedious task. The master decided to mechanize the process of chopping nuts. The nutcracker made by him is driven by a screwdriver and has an adjustment of the loading hole. Those. in this device you can chop different nuts, from walnuts to hazelnuts, possibly even pine nuts.

So, the master used the following

Tools and materials:

-USHM;

-Lathe;

-Drill;

-Drill;

-Welding equipment;

-Vise;

-Reducer;

-Bearings with pillows;

-Metal pipe;

-Metal corner;

-Sheet metal;

-Fibreboard;

-Fasteners;

-Key;

- Profile pipe 12 * 12 cm;

-Pliers;

-Metal strip;

- Aerosol can with paint;

Step One: Shaft

The master made a shaft from a round pipe. From both sides, welded metal plates to the ends of the pipe. I cut them by the diameter of the pipe, turned them.

A through hole is drilled in the center of the shaft.

A tube of suitable diameter and size inserts into the shaft bore. The ends of the tube are slightly machined along the diameter of the bearing.

Then the tube is welded to the shaft.

Step Two: Connecting Shaft

The gearbox is connected to the walnut shaft using a connecting shaft. At the end of this shaft, the master welded a key.

Step Three: Case

The housing is made of a profile pipe 12 * 12 cm. In the housing, holes are drilled for the shaft, mounting the bearing pillows, and two adjustment bolts. A shaft and a metal plate are installed inside the housing. The distance between the shaft and the plates is adjusted by bolts. The bolts are screwed into the bolts welded to the body.

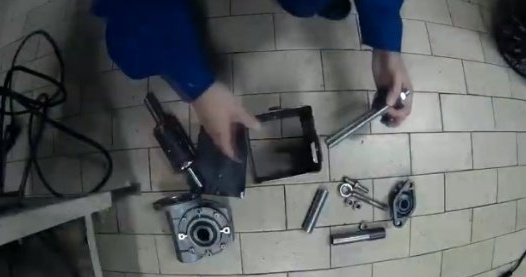

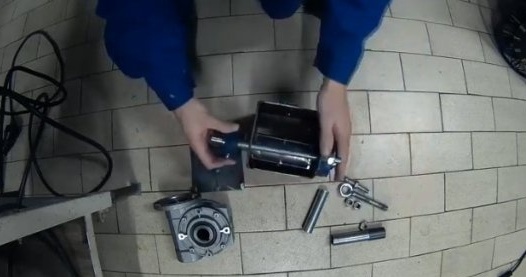

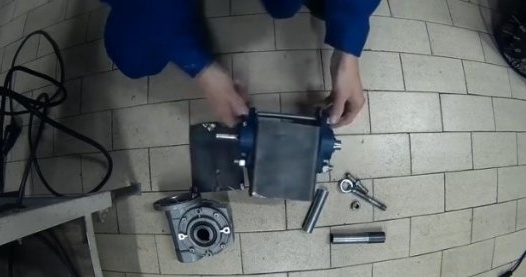

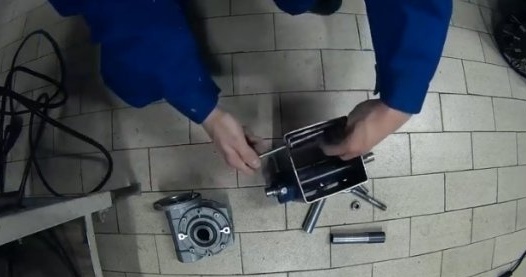

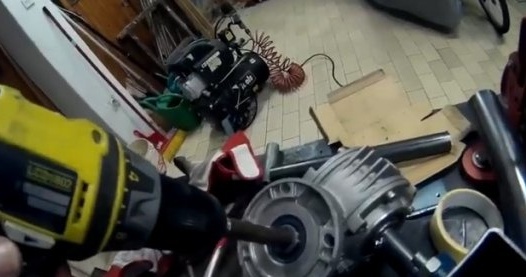

Step Three: Pre-Build

The master collects a nut cracker and checks its work. Mounts bearings and shaft.

Secures the plate.

Installs a connecting shaft.

Checks the operation of the device.

Next you need to paint the case. The master screws the metal plates (the frame of the loading hopper), and parses the nut cracker.

Step Four: Painting

Then the master paints the case.

Step Five: Final Assembly

The paint has dried, and the master again collects the nut cracker.The walls of the feed hopper are cut out of chipboard.

Now you need to adjust the distance between the shaft and the plate.

All is ready. Now you can load the nuts into the hopper and start chopping.

The whole process of making a nut cracker can be seen in the video.