Hello dear friends, today we will forge a knife from a hook from the slings. I don’t know the grade of steel, but sparks like good steel. I made this knife about two years ago, it proved to be excellent in use - how many I cut the tires with it, and sharpened it twice, it turns out hard. So here we go, here is our test subject

I measure the place of the cut on the hook, I did not leave it whole, I'm not sure that there will be enough nerves for its alignment, so I plan and saw off

Now rekindle my hearth. I have it small, but udalenka, like putting a crowbar in it, I wanted to heat it and level the tip and while I was smoking it heated up and when I decided to forge the crowbar I took it out and it melted

I warm the hearth and put the workpiece and heat it up almost to yellow-white

I cool it for a couple of minutes, then warm it up again, but already to the scarlet color

I start forging where the bend is, thereby aligning the workpiece

Metal forges well, I begin to form a handle

Well, something turns out like a knife, but still a lot of work

Next, I thin and stretch the handle smoothing the edges

I decided not to leave the ring like that and ivy it a little drowned

Well, almost now I’m cooling and considering, it seems convenient to hold in my hands, I warm it up again and eliminate all the shortcomings

That's all, the handle is now ready to proceed to the blade. I form the general profile of the blade, pulling and thinning it

Thickness somewhere 3mm smooth out all the bumps

Now I form the tip of the blade, betraying the final look. Then I punch the entire area with a metal ball not much so the blade will become stronger

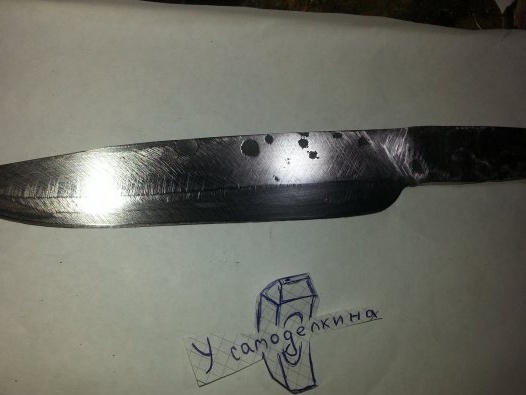

Well, that’s it, the horn can be put out, everything is forged. Now proceed to rough grinding the area

I bring down the slopes on the sharpener is not quite even, but it looks nice

Well, it remains to grind a few. Initially, I did not plan to grind the knife in the mirror and therefore I grind it with fine sandpaper manually

Something like this.

Well, our brutal knife is ready, thank you all for your attention!