In this article, the author of the YouTube channel "Crazy Workshop" will tell you about the method of manufacturing a budget jigsaw machine.

A project can take a lot of time, but if you have the tools, it can take less than a day.

Materials

-

- Old jigsaw file

- sheet plywood

- PVA glue

- paint

- Sandpaper

- Rod, sleeve, spring

- Wood screws.

Instruments, used by the author.

-

-

- Welding machine

-

-, cutting disc

- Orbital sander

- Neiler

-

- clamps

- Drilling machine

- Crown for wood, feather drill

- Vise.

Manufacturing process.

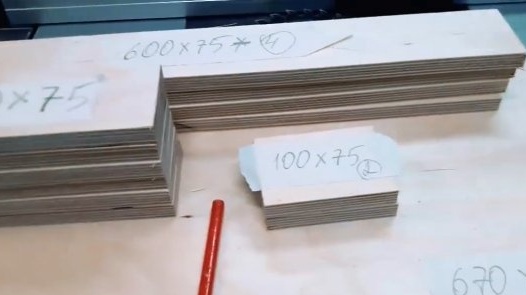

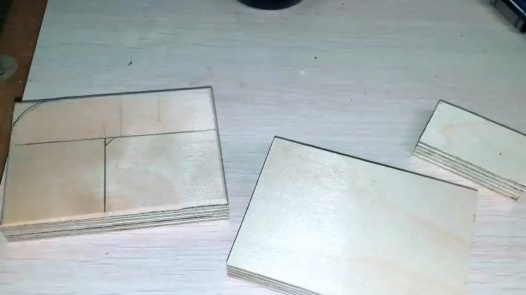

To start the project, the author cut out plywood in the following sizes:

6 blanks 280X75 mm

4 blanks 600X75 mm

2 workpieces 100X75 mm

and one for the working surface of 670X340 mm.

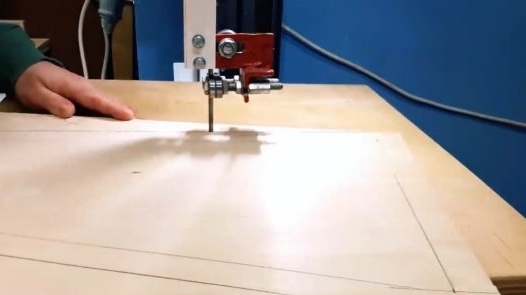

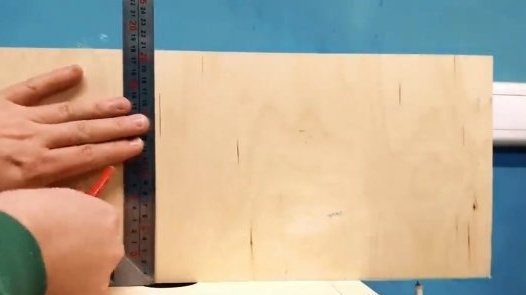

Then he marked out the blank for the table, and cut it with a band saw.

Edges of the countertop processed on a grinding machine.

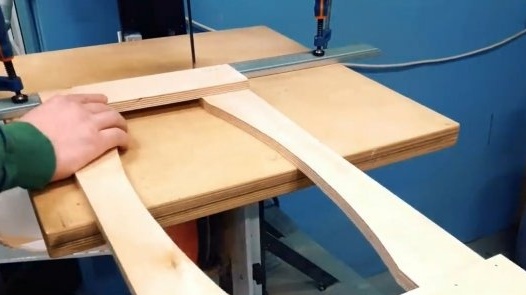

Four pieces of 600X75 mm were connected together by adhesive tape, and made an arched cut.

Then he began assembling the side supports of the table, gluing the blanks together, and fixing with a neiler.

The edges of the resulting blanks trimmed on a band saw.

And he began to assemble and glue the supports.

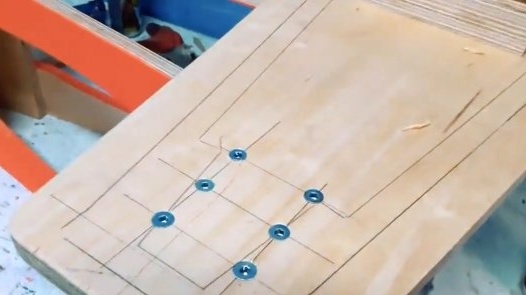

Jumpers are additionally fixed with screws.

The base of the table is ready, you can try on the countertop.

Then he took an old file from an electric jigsaw, and sharpened its teeth.

Such a blade holder with a hook was welded to the front edge of the file.

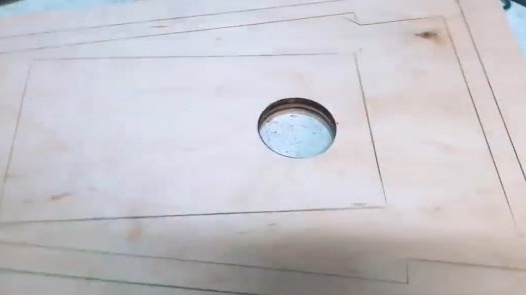

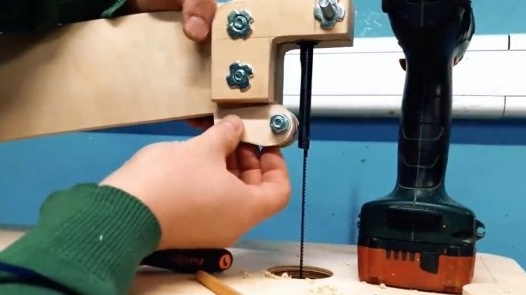

Approximately trying on a jigsaw to the countertop, drilled a working hole. It will be needed for quick access to the blade holder, and will be closed with an additional lid.

Now you need to make pads for the jigsaw.

He drilled a hole of a slightly smaller diameter in the liners with a pen drill than in the countertop. Then I marked and glued both pads to the bottom of the table.

Then he screwed the jigsaw sole to the pads, and set it in place.

Set the supports on the countertop, and sanded all the elements.

I screwed the supports to the countertop using furniture corners.

Now the master begins to manufacture the upper web tensioner. To do this, you need a rod, sleeve and spring.

Assembled the upper part of the tensioner.

Using a caliper, he transferred the dimensions of the sleeve to the blanks for the holder.

Now cuts blanks for the shoulder holder and tensioner holder.

At the end of the stem, the author marks and cuts a slot for the canvas.

Here's a hook with a slot on the stock.

Drills the required holes for the sleeve and mounting bolts in the holder.

Trying on all the shoulder mounts.

Then he paints the racks, turns the device upside down, fastens the racks to the base.

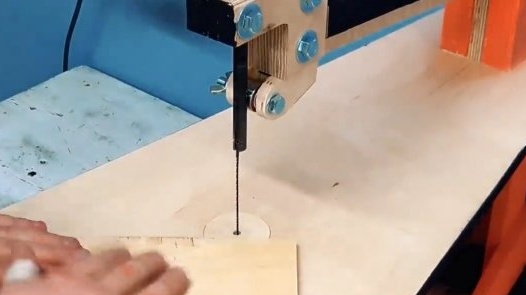

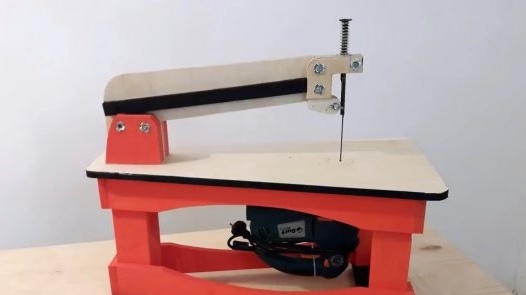

At this point, the table looks like this.

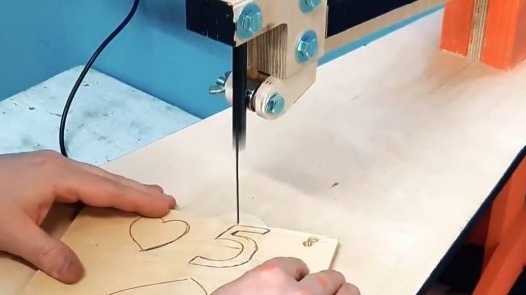

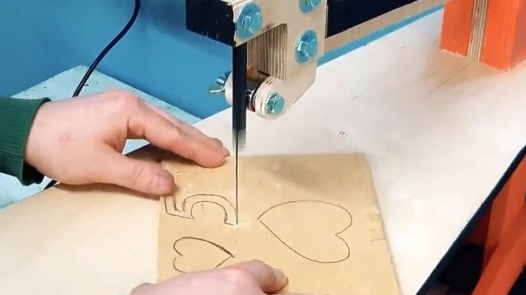

Sets a sheet of plywood, and puts markings on it for cutting.

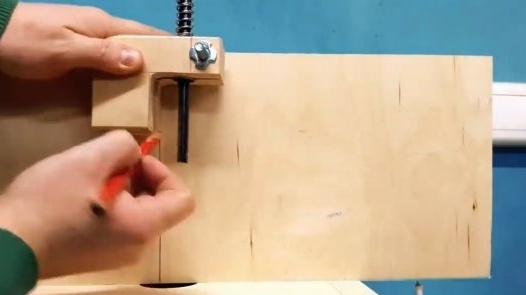

The cut shoulder is fixed with a clamp in the racks.

Screws the holder to the shoulder, and it to the uprights.

Now it assembles the design of the thrust bearing, and fastens to the holder.

Sets the blade in its place, first to the jigsaw.

Then puts on a protective cover, throws a cloth into it, and fixes it in a tensioner.

The machine is ready for testing! Even small details are given to him very easily.

Thanks to the author for the idea of a very useful workshop machine!

All good mood, good luck, and interesting ideas!