Not so long ago, the author of the Bonn Factory YouTube channel made a huge ax using welding and a grinder. And this time with the same tool we will make a ring with you a few grams.

The author was so impressed with this idea that he decided to start literally from scratch. And to start we need a copper plate.

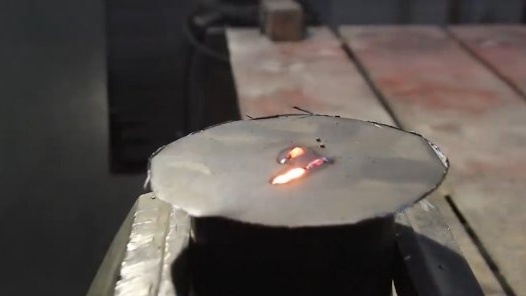

Due to the enormous thermal conductivity under the action of an electric arc, copper melts much later than steel, and this will allow us not to alloy metals together. And in order to surely not weld copper with steel, we will cook at the minimum mode, which now will need to be selected.

To do this, you need to take a steel plate 1.5 mm thick and just try to weld the seam.

Metal burns easily. You need to adjust the mode a little more.

Excellent! Pleasant rustling in the process indicates a well-chosen voltage and wire feed speed. There are no burns, which means we proceed to surfacing.

While the workpiece is firmly held on a copper substrate, you need to bring out at least one plane with which all marking will begin.

Now, with a chisel, you need to bring down the deposited bagel.

Why doesn’t he fight back? You will have to spend a little more time than planned.

So, after the separation of the metals, you can see how in places of direct contact with the welding wire, the metal nevertheless grabbed a little. This could have been avoided by careful welding of the weld metal, rather than igniting the arc from the plate.

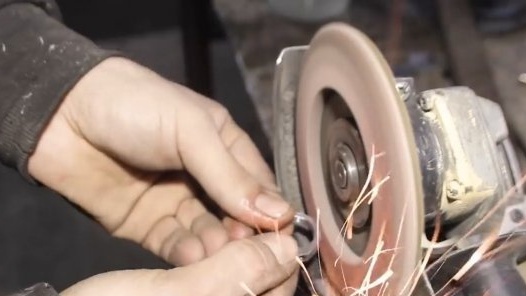

Now we remove sharp notches so that the ring can be held in hands without gloves. We process the inner surface with a milling cutter, and then the outer surface with a cleanup wheel.

Now we drill a hole under the stone. The author used a drill with a diameter of 4mm.

When working with such small products, the grinder has to concentrate very much and strain, which is why fatigue did not take long. Therefore, the author still entrusted further processing to the file, and the finishing polishing of the drill and emery.

We will fix the stone with a diameter of 4 mm.Exactly the same diameter, the author drilled a hole under it.

Since steel is much harder than non-ferrous and precious metals, the master will fix the stone with a hammer. Although it is unlikely that someone will condemn him for this, if you remember that he made the ring a grinder.

And now, our little ring is ready.

Let's summarize. It was an interesting experience, the entire manufacturing process took 9 hours from the master, after which it was possible to create a pretty ringlet literally from scratch. The author hopes that this homemade product will become motivational and show that the main desire is, then experience, and only then an instrument.

That's all. Thank you for attention. See you soon!

Author's video: