1 step. History.

Now it seems to me that this stanochka has been with me for ages. But, this is somewhat wrong, he appeared with me only in 1979. Almost a year before that, I did it.

As a schoolboy, he was engaged in ship modeling, and then amateur radio. Yes, and made masters around the house. I always lacked the production base, so to speak, of course - machines.

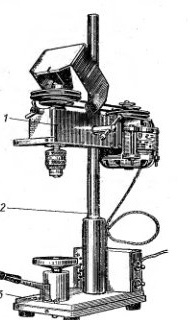

And somehow I bought, on the occasion of a little booklet, it was called "Radio Amateur Technology" by V. V. Frolov. DOSAF Publishing House. Many interesting things could be gleaned and applied. And almost at the very end of this book were given drawings of a universal desktop machine.

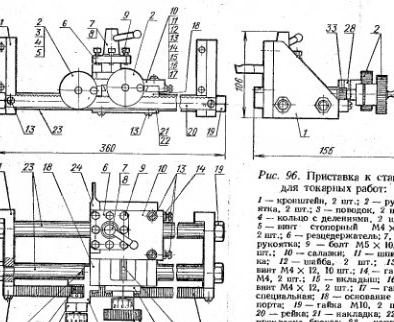

And, further, even more interesting - a turning attachment to it.

And, the main thing was a detailed description of this universal machine.

And here, I realized that this is mine, this is what I thought and thought about for so long, and what I missed so much.

2 step. Manufacturing and assembly.

At this time, I was already working at the factory, after college.

I talked with friends and acquaintances machinists, said they would help. In other words, where for thanks, where for exchange, and where for money, I began to order machine parts. Once, he himself remained after work and put to a free workbench, in the second shift. After some time it was already possible to collect something. In general, things have gone.

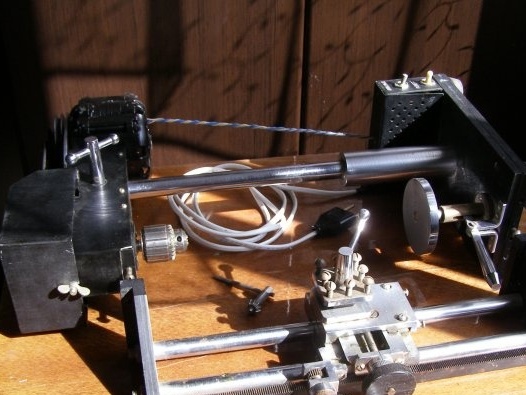

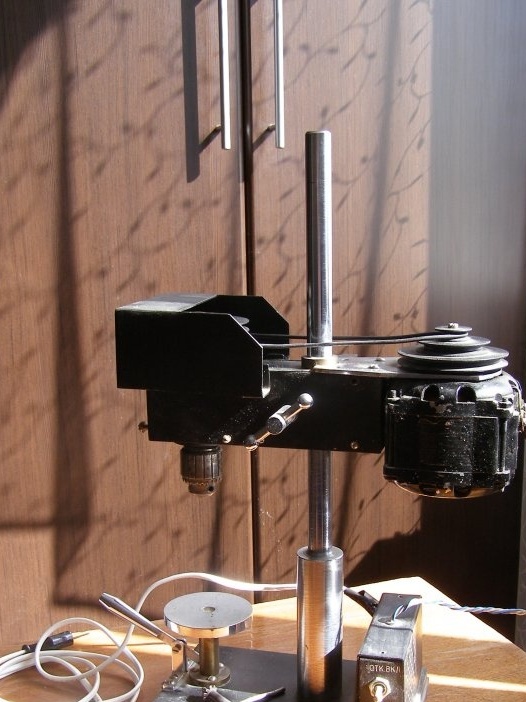

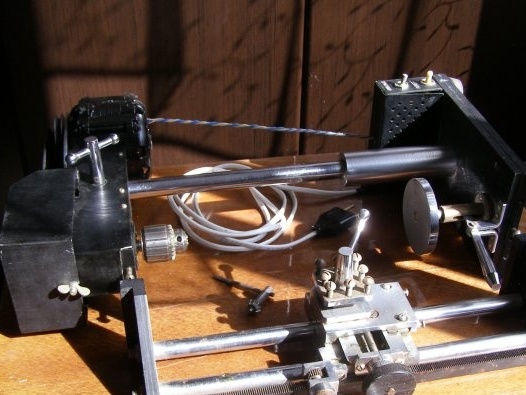

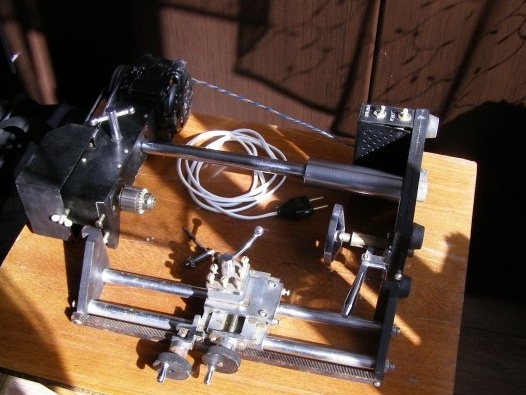

The machine is not large, bed 120 x 300 mm, height 440 mm. The spindle extension itself is 72 mm, at the end of it the Morse 1a cone is shortened, the table travel is 20 mm. You can drill holes up to 10 mm, of course in a soft material. Well, a trifle, like holes in a circuit board, is generally one or two. Now recalling this time, I will say this - my soul sang and danced.

In short, he made it and for many years now he has served me faithfully.

True, he does not have a big catch, this is a vertical serving table (and even a round one). I, then, did not attach any importance to this. Yes, and working without yews, this does not affect how. And, here with yews, it’s difficult. They simply did not enter it.

Most drilling machines drop the spindle with the chuck to the part, and this one raises the table with the part to the spindle. The machine operates from 220 volts.

The machine switching (control) unit is located in a black box behind the counter. Pretty comfortable.

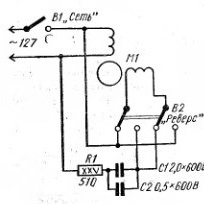

It included: two toggle switches "Network" and "Reverse", this clearly does not need to be explained, two capacitors and a powerful resistor in the phase-shifting winding circuit.

True, for what, the reverse switch is not clear. For the entire period of operation of the machine, I have never used it.

The revolutions are changed by pulleys; three speeds of rotation of 330, 1420, 6100 revolutions per minute can be set.

If you put the machine on the left side, then you can attach a turning attachment to it.

Having worked on a turning attachment, I realized that in most cases a rear center is needed, and a chuck for drilling holes along the part axis. Ah, they are not. He designed the tailstock himself and almost did it, but somehow it did not work out. Over time and moving details are lost. I still work without her.

3 step. Modernization wagon.

Over time, I came across a motor from a sewing machine with a pedal and a backlight. Of course, I replaced the low-power KD-2 engine, which was originally installed, with a more powerful one from the sewing drive. Yes, and with backlighting it began to work much more interesting, but the pedal didn’t take root in something. The angle of the pedal itself is a big tired leg. I removed it.

After some time, the sewing drive was covered, and I returned to the previous engine.

The latest modernization of the station wagon was more thorough. The reason was another engine failure. Well, these days a little easier. Found a replacement.

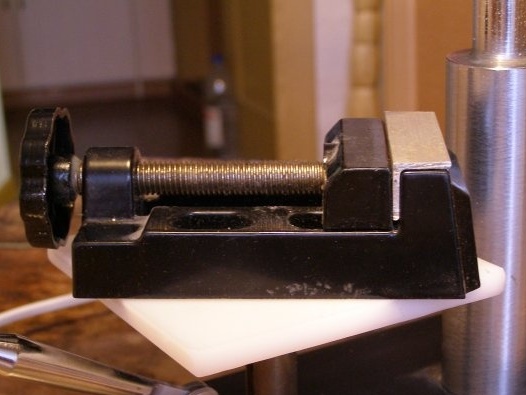

For one, I decided to increase the surface of the table. That it would be possible to work with a vice.

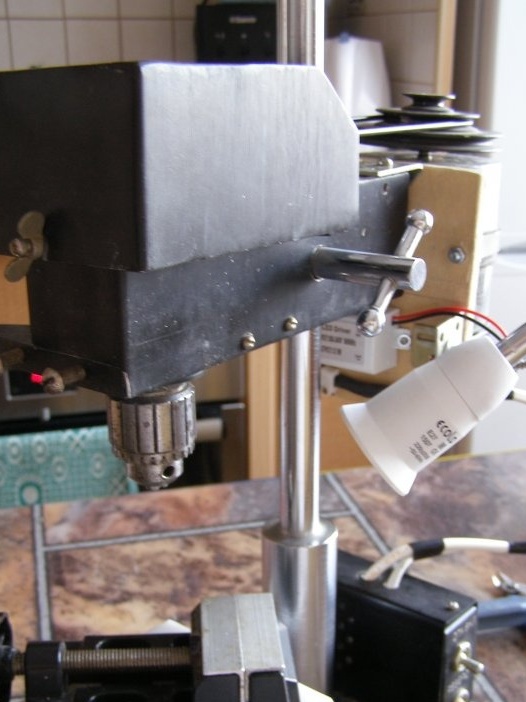

Replaced the lighting lamp. In a hardware store, I came across a NOVELTY - an adapter plug-cartridge E27 with a switch. Seeing her, I immediately realized that this is a solution to the problem with lighting on the wagon, of course with a little revision.

Before that, I had bought and laid in stock the G770 LED spotlights for 220 volts. Offhand, I thought that such a lamp is just suitable for such a cartridge as E27, which will be a good body for him (the lamp). Yes, and on a bent leg. Everything came up, as I expected. The matching unit for the power supply from the lamp placed on the bracket for mounting the motor. The lamp is fixed there in the corner.

Well, that’s the whole story of creation.

If anyone, interested in the drawings, and he can not find on the Internet. Write to me, I will share it with pleasure.

Good luck to everyone and good ideas.

See, criticize, advise, ask.

Regards, Starp.