Hello everyone !!!! More recently, I made a mini lathe with a maximum workpiece length of 15 cm, I worked on it more than once and realized that the maximum length is small and suitable only for making handles for knives and tools. And he decided to rebuild the machine with the adjustment of the length of the workpiece and with the adjustment of the platform of the stop of the cutters.

And so we need a 50x100mm tee, a piece of corner or profile

So, we make a cut in the middle of the I-beam 20cm, for the direction of the site, we drill a hole 6mm, stepping back from the edge 1cm

Now I cut off the guides from the old machine along with the corner

Trying on my place

Trying on my second place

I brush with metal. I make a cut 8cm

I brush the I-beam

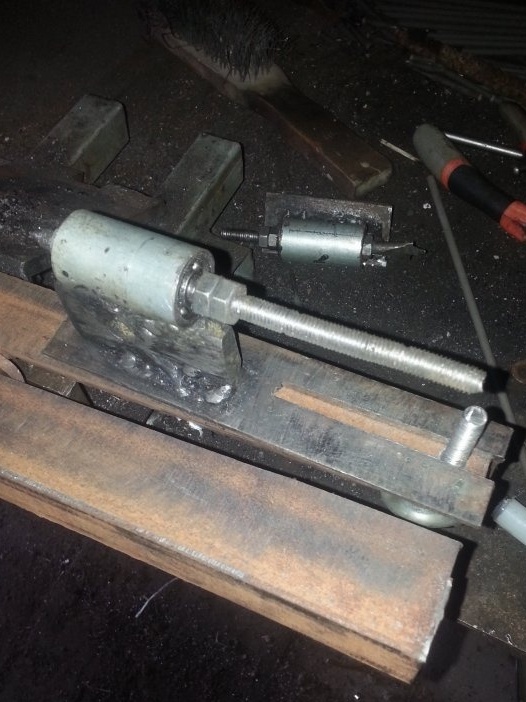

I put a bolt and try on. The bar goes without distortions

I weld a bolt and make a limiter on the bar

I weld a piece of metal on the edge of the corner so that the bar does not walk along the plane

I center and weld the second bar to the I-beam

Well, everything is in place, trying on a blank

Now I am transgressing to make an emphasis for cutters. To do this, you need a piece of profile 40cm 25x50mm and a piece of metal

I make a cut on a piece of metal almost to the end, try on the profile and weld.

I drill a hole in the I-beam by 4mm, and then drill a 6mm drill. I insert a bolt from the inside of the I-beam and weld, put the bar in place

Well, that’s it, I sort it out, sort it out with a brush for metal and hide with large emery paper, degrease all the metal with a solvent, and in two layers with a difference of two hours I paint everything with a gray primer, maybe I'll paint it in some color.

And so the conclusion: now the minimum length of the workpiece is 10cm, and the maximum is 40cm, now the adjustment has become more functional and the platform is regulated even under the longitudinal degree. It also became more convenient to work, and you can not only do pens.

Well, that’s all. As will the time, I will grind something and report to this archive. With this machine you can sharpen workpieces up to 80mm. I hope I learn to sharpen something beautiful. There is a problem with the material, except pine and birch.It’s necessary to somehow forge the incisors, and in our time everything done looks beautiful when it is on the shelf, and how you start to do something with them or bend, or even break, but you’re much better at least from what this is done, obviously for yourself from aluminum you will not do.

I used to see a lot of beautiful things turned on a lathe, and always wanted to learn this way. At school, we had two lathes, the current teacher was a redneck, the teacher never let me work, he always said: he’ll kill me, and he called me “Pigtail” for you. Once I talked to him for a lesson, so he did it all himself and sharpened it, I only skipped it at the end.