Hello to all lovers to craft and knock on red-hot pieces of iron. Today we will make a small chopping hatchet, they can chop bones, meat, chop branches and do many more useful things. An ax is made by forging by craftsmen from Cambodia. Manufacturing methods are used quite primitive, like tools. If you do not take into account the grinder and jigsaw, everything is done according to a rather ancient technique. The master’s work is quite clean, the ax doesn’t even require grinding. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- piece of iron (it would be nice to use carbon steel);

- a piece of board for the handle;

- Super glue.

Tool List:

- forge furnace;

- an anvil, hammer and other forging tools;

- a grinder with a grinding disk, as well as a Velcro for sandpaper;

- jigsaw or hacksaw;

- drill.

Hatchet manufacturing process:

Step one. Forging

To begin with, the master launches his wonderful stove from the barrel, pulling the rope, thereby fanning the coals. We heat the workpiece to a red glow and proceed to forging. First, chop off the back of the workpiece so that the future handle is obtained. Well, then gradually, slowly, we make the metal thinner and thinner, as a result, the silhouette of the hatchet begins to form before our eyes. Of course, the metal will at the same time increase quite significantly in area and it needs to be constantly trimmed. The author simply cuts it with a special wedge, hitting it with a hammer. Thanks to forging, the steel becomes thinner and stronger, and if high-quality metal was used, then the ax will turn out to be very strong and sharp.

We turn to the handle, pull it to the desired length, we need to make holes for the handle in the handle. For this, the author uses a special drummer and punches holes. The ax is almost ready, we warm it and carefully work with a hammer to level the planes. Shots should be gentle, but frequent.In the end, gradually cool the ax, temper until it is needed.

Step Two Grinding work

We fix the hatchet in a special improvised fixture and proceed to grinding. For rough processing, you will need a grinder with a thick grinding disc. Align the ax along the contour, and also grind if necessary a plane.

As for the bevels, their author forms manually already using a file for metal.

Step Three Quenching

We proceed to hardening, this will make the blade durable, and it will not be blunt for a long time. The author tempers only the blade, as a result, the ax itself will not be fragile, which is important. We heat the blade on the coals, and then immerse the hatchet blade in water. You can also harden a little hatchet butt.

After hardening, we grind the product a little, as it will change color.

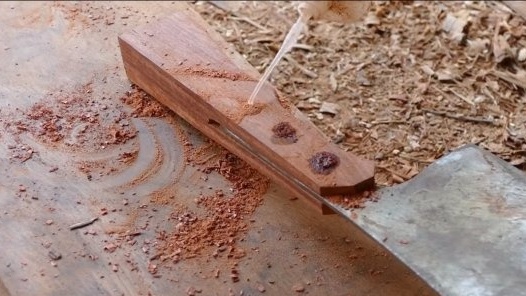

Step Four Pen assembly

We proceed to the manufacture of the handle, we need a block of suitable size, cut a slot in it with a jigsaw or a hacksaw under the tail of the knife. Well, then we fasten the handle by drilling holes, here the author uses self-tapping screws. The heads of the screws are buried in the handles, on top we close the holes with sawdust and pour superglue on top. The glue should go inside the handle, now the connection will be very strong and reliable.

At the end, we grind the handle well, set the desired shape, work as a grinder, using the Velcro nozzle for sandpaper.

After that, the hatchet is ready, it remains only to sharpen it. As an experiment, they gave a hatchet to a woman; she easily cuts a rather thick branch. On this project can be considered successfully completed, I hope homemade you liked it, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!