Almost everyone had to raise or lower something in life with a rope. Some workers specialize in the constant movement of goods up / down. It’s good when there is someone to unhook the load below, and if you are alone? Of course, you can use the usual hook, but it will be safer to use a carbine invented by the master. With it, after lowering the load, the rope with the carabiner is easily released and they can be lifted up to secure the next load.

Let's look at the video how the wizard does it.

As you can see, everything is quite simple and reliable. By the way, the master has already received several commercial offers regarding his carbine.

Tools and materials:

-Computer with software;

-Aluminum plate;

-Rope;

-Milling machine;

-Laser cutter;

-Aerosol paint;

-Wire;

-Pliers;

-Vise;

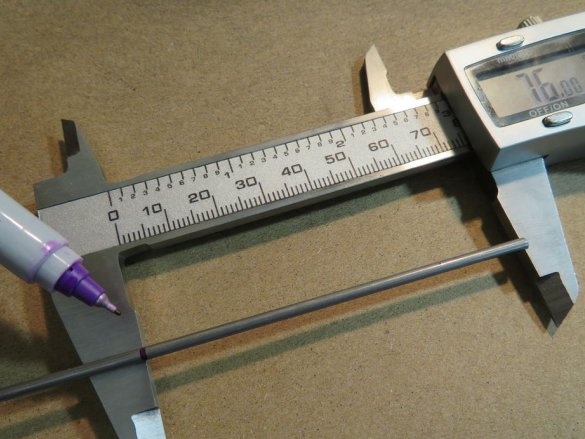

-Calipers;

-Marker;

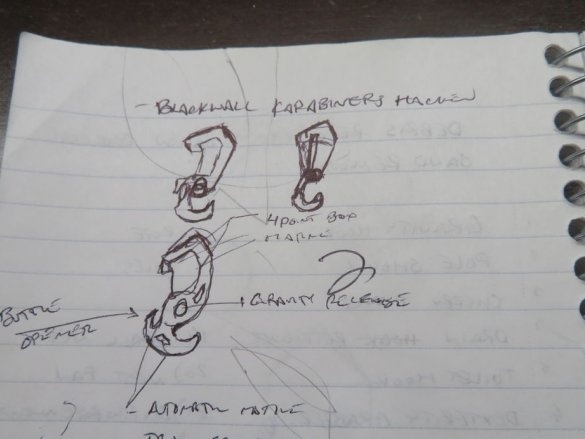

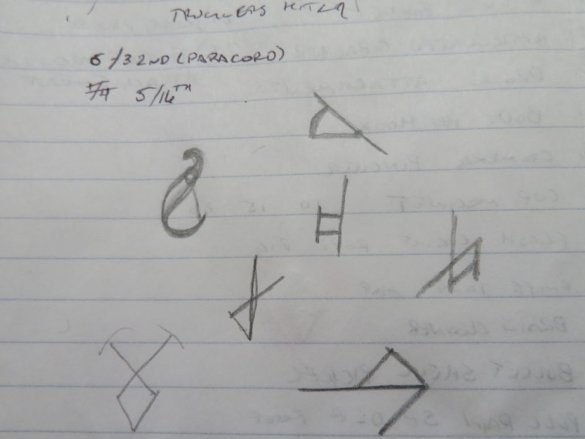

Step One: Project

Thinking of making a detachable device, the master went through several options. At first he wanted to make a device in the form of a hook. But then I realized that the load could put the hook overturned and release the rope.

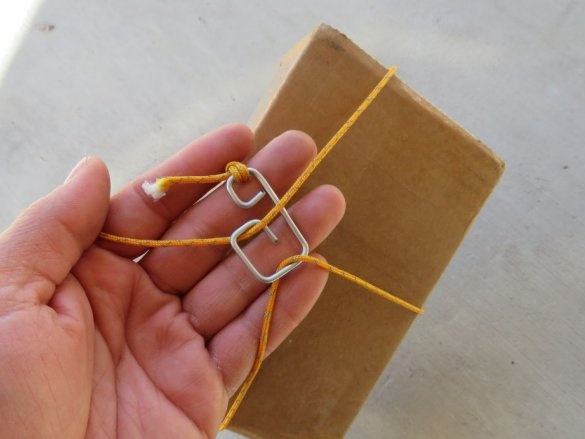

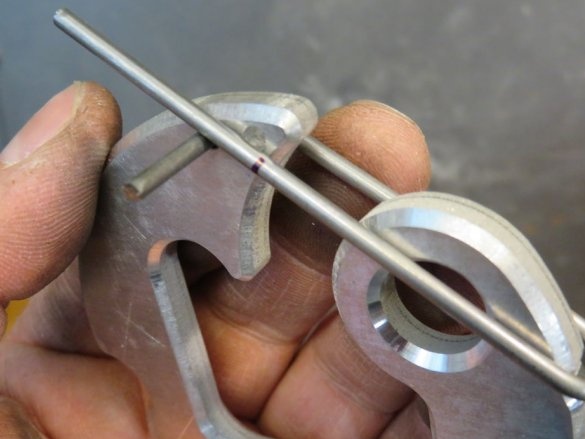

As a result, first from a wire, and then from an aluminum plate, the master made a prototype carbine.

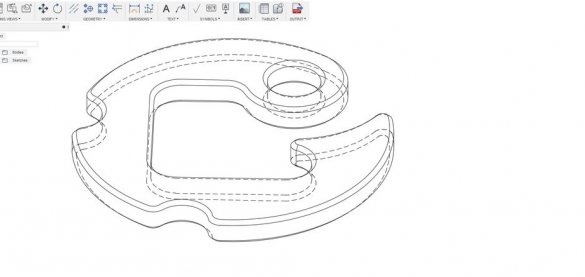

Step Two: Computer Processing

When the master understood what shape the carbine needed, he set about fine-tuning the design on the computer. The carbine diameter is 7.62 cm (3 inches). There are two semicircular cutouts on the end of the carbine so that the rope does not slip. After the master was satisfied with the result, an order was made not to manufacture five carbines in the workshop.

Step Three: Milling

Carbines were carved on a CNC machine and sent to the master. Now you need to process the product on a milling machine.

Step Four: Shutter

Shutter, the master bent the shutter out of the spring wire.

Step Five: Painting

Now it remains only to paint the carbines.

The carbine is ready and the master tested it at work and used various methods of fastening.