Hello everyone !! The other day a friend drove me a piece of spring steel from a truck, and I decided to make my first Yakut knife out of it. After watching the video, reading the articles, I decided to start making a knife. Here is this very piece.

I heat the metal in the furnace to scarlet two times, let it cool, so the metal will become easier to process. I heat the metal to the temperature necessary for forging, the main thing is not to overheat the metal, and not forge very cold, I treat the heated area with strong blows with a two-pound hammer, as the metal is hard and forges heavily.

I apply pulling blows forming the overall profile of the knife, not forgetting the thickness of the blade.

The Yakut knife differs from all knives in its hole in the blade, holes are in different places, different in shape, this kind of knife is also sharpened on one side. In general, there are a lot of types of the Yakut knife, for my knife I chose a central knockout, sharpening from the opposite edge.

I’m starting to cut the center, for this I found the ball from the bearing, the ball will go anyway, so that the handle is welded to it for the convenience of working with it, I punch the blade of the knife.

I heat and punch, smoothing the shape of the picture

On the opposite side I round the blade. Well, with forging for today.

I proceed to hardening. I cut the handle, forming a shank. I heat the knife to the temperature necessary for hardening the metal, while heating I check for magnetism. After the knife stops magnetizing, I dip in heated oil up to 40 degrees, and so five times, after heating and dip in cold oil, until the blue appears on the knife, and by the final step I heat the blade and dip, only the blade in cold water. All tempering is completed.

Now the metal needs to be released, for this I put the knife in the oven at a temperature of 200 ° C for 2 hours.

Now, on the grinding machine, I remove the unwanted metal around the edges, periodically cooling the knife, you can not heat the blade, otherwise all work is spoiled, rushing will not lead to anything good.

I round the second side of the blade, grind a little

Well, that's all with the blade, now I proceed to the handle.Like about 2 years ago I sawed myself a mouthpiece, suvels of different types of wood, such as birch, pine, aspen, poplar, elm, aspen, cherry, maple. It hurts too much in my honor, the reserves are not large, but for now enough, how will the time need to replenish the reserves. For my Yakut knife, I took a cap of maple and polished the shape I needed on a thinner machine, here it is.

Having drilled a hole in the center of the handle, I fill in a little epoxy glue and mount the handle on the knife.

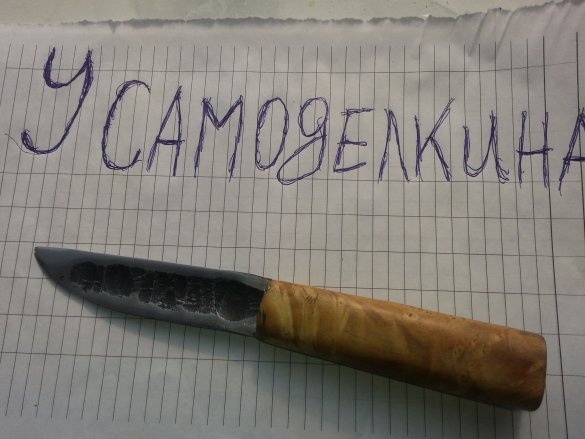

Well, now I go through everything with a fine emery cloth and polish the goya paste as best I can.

Well, that’s all, my first Yakut knife is ready, then it remains to polish in the mirror. Metal in processing is not very capricious, the main thing is not to overheat it, and in general it is not bad. And so for today, thank you for your attention and to the new Homemade friends...