In this article, the author of the YouTube channel "Pask Makes" offers you a homemade knurling machine. What could be better than tools made do it yourself!

The author in previous articles has already applied the technique of rolling bolt heads manually using a file clamped in a vice.

Despite the effectiveness, this is still a pretty tough method. Now the master decided to improve it by creating a knurling machine.

Materials

- Bolts, nuts, washers

- bearings

- steel strip

- Masking tape.

Instruments, used by the author.

-

- Vise, pliers, file

- Drilling machine

-

- Belt sander

-

- Gas-burner

- Spanners

-, core, square.

Manufacturing process.

First of all, the author cuts blanks for fixtures from a steel strip.

Then he will have to fasten one large steel part with two smaller sizes. Bolts will serve this purpose. Parts could be welded, one of the parts should remain movable and slide back and forth.

A pair of slots will be made in the same wide detail. To make them, he drills two rows of holes.

When the preliminary holes are ready, a file is used.

These are the grooves for the bolt head with a square head.

Then he drills holes in the guides.

To prevent the bolt from spinning, the master cuts the round hole with a square file.

He fastens the movable plate with bolts and wing nuts.

And now he is preparing the holes in the second, movable plate.

Having fixed the second plate, it is now clear how this will work.

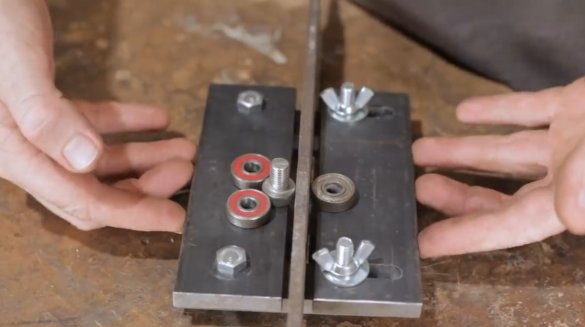

There will be two bearings on the fixed plate. The author will drill holes and screw the bearings in place so that the screw protrudes slightly beyond the edge of the plate, about 3-4 mm. There will be one bearing on the opposite side, but it will already protrude somewhat so that a file can be passed along it. And pressure on both sides will be applied to this entire structure, it will be compressed in a vice to ensure that the bolt clamps between the bearings and the file.

In addition, the author plans to make the same system next, only for bolts with a smaller head.

Now the author is marking up future holes.

This is how the whole set of parts looks.

After assembly, the device looks like this.

Now the master grinds the head of the bolt, holding it in the chuck of the drilling machine. But first, he covers his thread with duct tape so as not to damage it.

Then he grinds off the sharp edges of the cap, clamping the bolt in the cordless drill chuck and grinding the cap on a belt sander. It also polishes a little with fine sandpaper.

So, the first test fixtures. Clamps the jaws of the device in a vice, and taps the file.

During test rolling, one bearing burst. This is probably a material defect.

Replacing the bearing with a better one did not affect the result.

Now the master plans to install two bearings in the same way in order to maintain mass distribution. Perhaps this is the right decision. Now the problem is with the bearing on the back. Probably, when the author knocked out the file, he did not turn the bearing so much as push the bolt. He then crushed the bearing.

In the next attempt, the master tightens two nuts on the edge of the bolt, and tightens them together.

Using a hex head rotates the bolt with a drill. The file is passively moving forward and backward. At first glance, the success seemed obvious, but something else happened ...

Knurling came out good, but the author clamped his vise too tightly. He does this if he wants to get a brighter knurling effect, and two bearings burst again.

For a week, the author tried to achieve the desired effect. As a result, he buys two pairs of knurled wheels. One for applying a diamond pattern, and the other for direct knurling.

I had to turn the plates, and drill new holes.

For the experiment, the master screws two knurled wheels, and in front of them one large, powerful bearing. The wheels sit on small washers, that is, slightly raised above the surface. Therefore, the bolt itself should be slightly raised.

The author achieves this with a piece of plastic, which, in the case of a successful experiment, plans to fix it on a steel panel.

So, he carefully shifts the vise, creating moderate pressure, and carries out a check. The machine is working! Knurling is almost perfect, but very distinct and uniform.

It remains to solder a pair of plates on the sides so that the machine can rest on the jaws of a vice.

After verification, the author disassembles the device and covers its parts with several layers of primer to prevent the appearance of rust.

On the machine, he installs both sets of knurled wheels. Since the file is no longer used (a screwdriver does its job), there is no need for the pressure bearings to protrude beyond the plate. This means that bolts of any size can now be processed on the machine. He also cut a lining out of plastic.

The master himself switches the screwdriver to the first speed, and again makes an attempt. This time the process is controlled as much as possible by the compression force of the vice and the speed of rotation of the drill. Believe me, mastery is also needed here!

Finally, the author checks the effectiveness of the machine on a softer material - a brass bolt.

The edges of the cap can also be ground in this way, and the upper part of the head can be sanded.

And the picture is more distinct.

The next to be taken is a galvanized bolt in order to give it a black patina. Knurling is great!

Then he makes bevels on the upper and lower edges of the cap, and repeats the procedure with several more such bolts.

In order for the black patina to appear, it is enough to properly warm the bolt until it changes color, and then dip it in boiling linseed oil and wipe it. The procedure can be repeated several times until the desired effect is obtained.

Returning to the stainless steel bolt, the author tries to release the metal somewhat by annealing in the hope that in this state it will be easier to knurled it.

And really, it helped a lot.

The author also found titanium bolts, but the knurling on them did not work out very well.

Here is such a knurling.

Thanks to the author for a simple but useful tool for the workshop!

All good mood, good luck, and interesting ideas!