In this article, YouTube author Pask Makes tells you how to make a small blacksmith anvil.

His previous anvil was too small, and had limited functionality.

Materials

- rail connector

- Steel square

- Steel sheet, bar

- Railway crutch

- Churbak

- Oil, paint.

Instruments, used by the author.

-

- Cutting and grinding and grinding wheels

-

- Drilling machine

- Belt sander

-

- gas horn

- Vise

- Scoobel

- Chisel, clamps, core, chisel, pincers.

Manufacturing process.

The master will use the old rail connector as the material for the slab.

He brushes off the rust with a grinder, and cuts the connector in half.

For marking the central hole, he uses a steel square, from which various nozzles will be made.

The master makes multiple cuts, and then cuts the steel from different angles. Then aligns the grinding wheel. But the master found this method too complicated.

He processes the second half in a slightly different way: he drills several small holes on a drilling machine, makes two side cuts, and then chips the material with a chisel. It remains only to grind down marks from drilling. This method turned out to be much easier and faster than the previous one.

The square comes in perfectly.

Then he welds both pieces together, the Seam has to be boiled and cleaned several times.

Then the excess material at the ends is cut off, and all surfaces are ground.

It remains to strip the central hole with a file, just fitting it to the dimensions of the steel square.

Four segments of equal width are marked on a separate steel plate, and a center for the hole is marked in the middle of each. These are future anvil mounts.

Then the workpieces are drilled first with a thin and then with a thick drill. Small revs and lubrication are important here.

Then the workpieces are sawn, and their faces are grinded on a grinding machine.

Now the legs are welded to the steel plate of the anvil, one on each side.

Four more plates are cut from the steel strip.

The author covers them with a square, fixes them with clamps, and welds them together without affecting the square itself.

It remains to boil the seams finally, clean them, and grind all the structural elements. The main part of the anvil is ready.

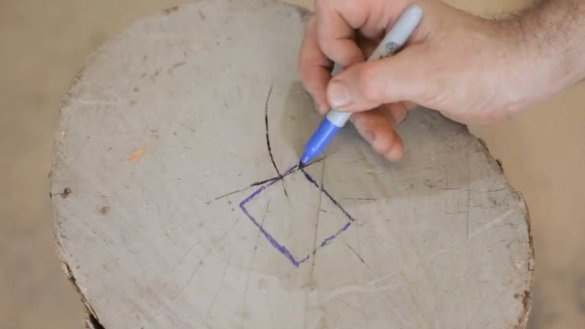

After that, the master cuts a block of suitable diameter. Levels the upper and lower surfaces so that they are parallel, and the block does not stagger.

It paints the upper section, tries on the anvil to the log block, and marks the places for excavation.

In the center of the log, he drills a hole, then extracts the remnants of the wood with a chisel.

Since the seams protrude a little, and interfere with the dense landing of the anvil, you have to slightly mow the upper faces.

The steel platform is installed in the block, and bolted to wood. For each bolt, a hole in the wood is pre-drilled so that it does not tear.

The bark is cleaned with an ax, and the edges of the log are somewhat smoothed out with a braid. How to make this tool, I wrote earlier in this article.

The bottom cut is also covered with paint.

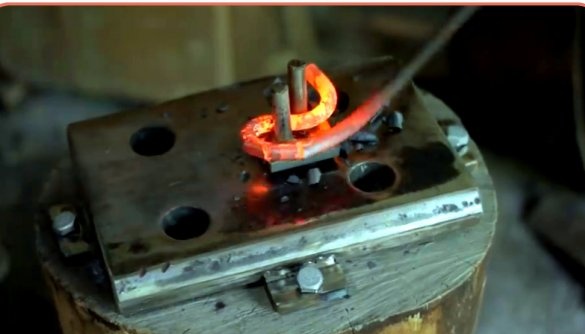

The author proceeds to the manufacture of auxiliary forging nozzles for the anvil. He cuts off the old train crutch, and heats it in the furnace.

Then he forges such a detail out of it, and quenches it in oil.

It remains to sharpen the cutter, and grind all sides. Sharpening such a tool is done at a fairly obtuse angle, about 40-45 degrees.

After forging and grinding, we get such a cutter. It is time to test it in action.

Now the author makes a primitive bending fork. Welds the rods to a metal plate, and on the other side - a steel square.

A very convenient nozzle turned out for bending even very small radii.

To this anvil, you can make many more different nozzles. Thanks to the author for useful device for a blacksmith!

All good mood, good luck, and interesting ideas!