It took charging for the car battery. After going through several options, I settled on reworking the computer's power supply. I decided to redo it in a simple way. The charger will not have adjustments, I do not have such a task. In principle, you can do everything in a couple of hours.

For homemade we will need:

- ATX power supply;

- wires;

- clips like "crocodile";

- network switch;

- foil fiberglass;

- plastic plexiglas;

- radio components;

- instruments.

About accessories.

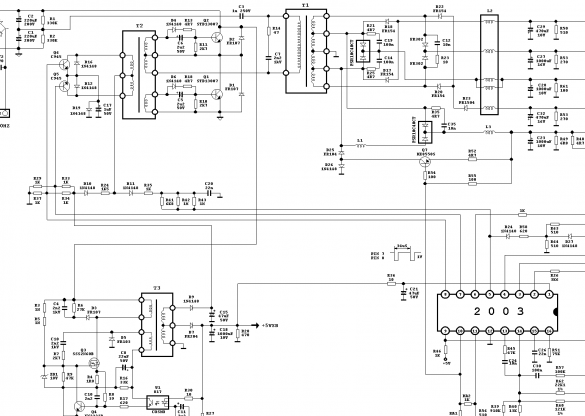

We will redo the ATX block. JNC company, model LC-D300ATX.

This power supply has a little-known on board chip 2003. There is little information on this chip. It seems like it's a PWM controller with a multivisor. We will understand the scheme, about the scheme below.

I will be connected to the battery using wires with crocodiles. I already had soldered.

As a network switch, I have a TV2-1 toggle switch. Pulled out from the old TV.

The power supply circuit is quite simple. We have a 300-watt block, a 250-watt circuit. The circuit may differ in the ratings of some components.

Assembly.

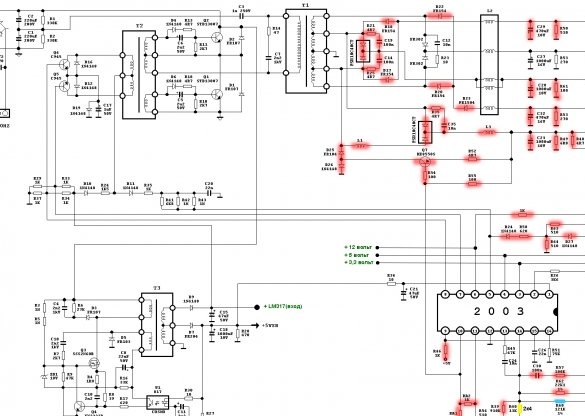

You need to remove all unnecessary components. Red indicates that it is necessary to evaporate. A yellow 13kΩ resistor is marked in yellow; replace it with a 2.4kΩ resistor. Instead of the resistor marked in blue, temporarily set a 200 kΩ variable resistor. A variable resistor, it is desirable to put on 100 kOhm, but I did not have this. I had to adjust the desired voltage for a long time.

The main thing is to set the maximum resistance. There are also green labels that I’ll tell you later what to connect to them.

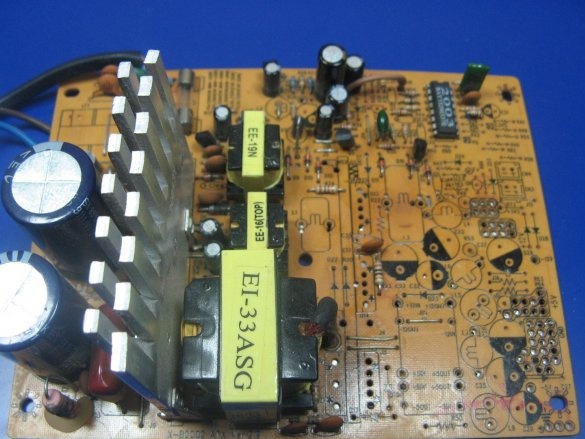

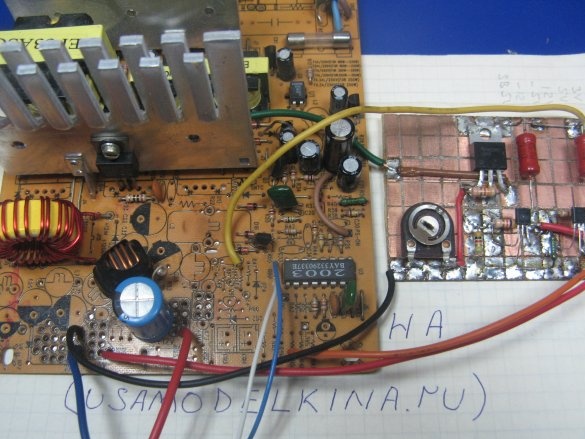

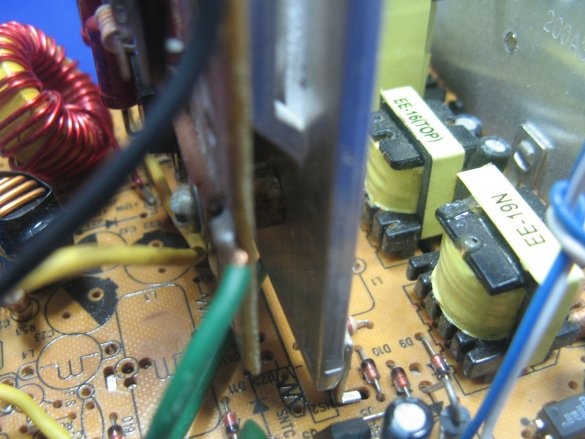

Solder the excess components. Everything is legible in the diagram. It turns out the board is like this. Temporarily dropped power diodes. Just throttle throttle group stabilization, I will rewind it. A brown jumper closed the spots from the ground and PS-ON, it is necessary to run.

We are interested in the +12 volt line. We put in place the power diode, I took the diode from the 5 volt line. The diode installed without laying. The legs of the radiator mount are not connected to the circuit, which eliminates the circuit. I installed an additional choke, in its place there was a jumper. I wound all the windings from the old group stabilization inductor, leaving the old 12 volt winding. Installed an electrolytic capacitor at 1000 microfarads, voltage of 35 volts.

A variable resistor is carried on the wires outside the board.

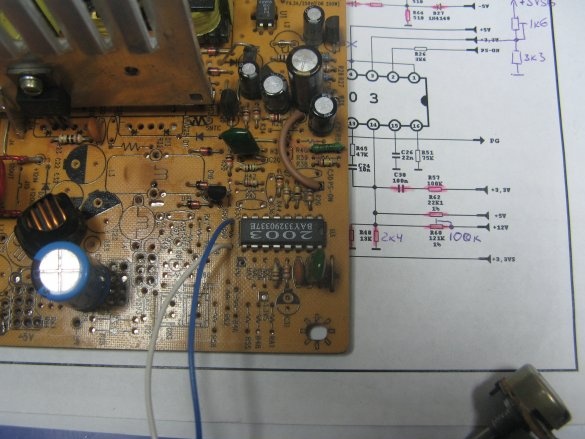

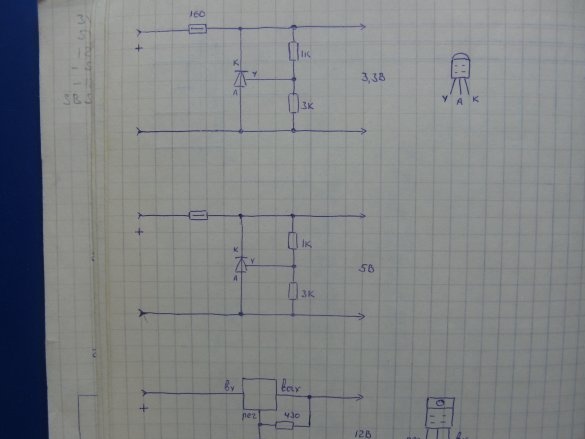

Now you need to make a board - a trick for our chip 2003.The bait consists of three stabilizers at »3.3; 5; 12 volts. Unsoldered according to a simple scheme. The upper two segments are assembled on TL431, the lower on LM317.

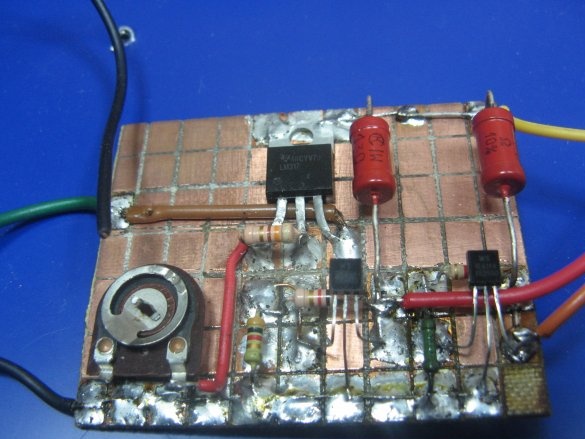

The upper two segments of the circuit are connected to the lower segment by 12 V. The scarf is made using the “scratching” technology. Done in about 30 minutes.

On the diagram, points were indicated for connecting the “snag” board. Solder in accordance with the scheme. The diagram is marked with green dots, respectively. The “snag” board has colors according to the voltage. It turned out something like that.

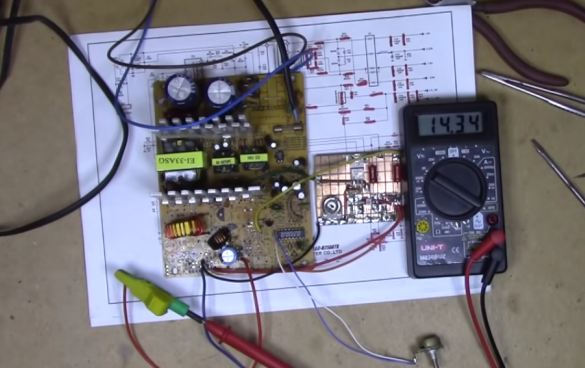

We set the desired voltage at the output with a variable resistor (forgot to take a picture). Leave a freeze frame. I measure the resistance of the resistor is about 11.7 kOhm. I assemble from two resistors of 10 and 1.8 kOhm. The voltage has changed a little, but not significantly.

The “snag” board was screwed to the radiator, through the sleeve and the M3 screw. Also in the photo on the left you can see that I installed the load resistor R53 back.

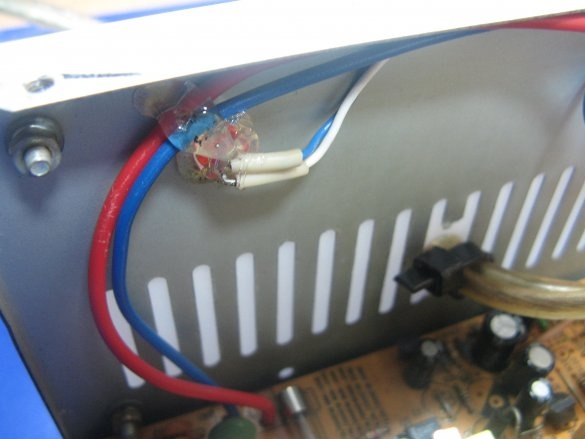

Connected wires with clips "crocodiles." Set the LED to indicate the inclusion. All fixed thermo glue. The network cable was released into the gap through the toggle switch.

Initially, I did not think of putting the plate on the front panel, but screwed it on. It looks decent. Such a garage charger turned out. The only thing that is not in this device is protection against short circuit and polarity reversal. Later, perhaps I will add.

The detailed assembly is displayed on the video: