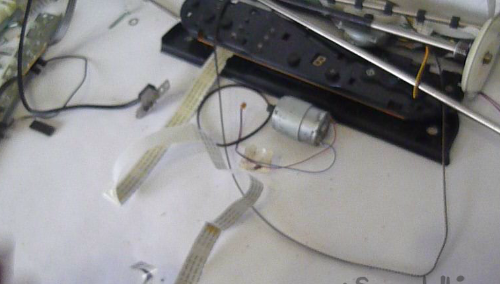

Many people throw a printer out of the garbage without thinking twice. But if you disassemble the old faulty printer, you can get a lot of the necessary parts for homemade. You can get high-quality metal shafts, rods, guides, stepper motors from the printer that you can use to create home-made CNCs and similar home-made products. The printer has USB connectors, a variety of position sensors. We use collector electric motors to create electric drills and to drive a variety of models and toys and so on.

In general, we give a second life to the old office equipment.

Now we will consider the topic of remaking the switching power supply from a Canon printer and its further application in everyday life. Printers are installed transformerless power supplies built on a pulsed circuit. They can produce voltages from 24 to 42 volts with a load current of up to 2 amperes. These power supplies are quite reliable, have a large resource and can work for a long time.

Enumeration of tools and materials.

- switching power supply from a Canon-1pc printer;

- tuning multiturn resistor for 5-10Kom -1pcs;

-connecting wires;

soldering iron;

-tester;

-1 minvoltmeter;

- glue;

- a piece of aluminum sheet;

- cap from the tube;

-plastic tube from the core of the fountain pen -1pcs.

Step one. Alteration of the circuit of the pulse power supply of the printer.

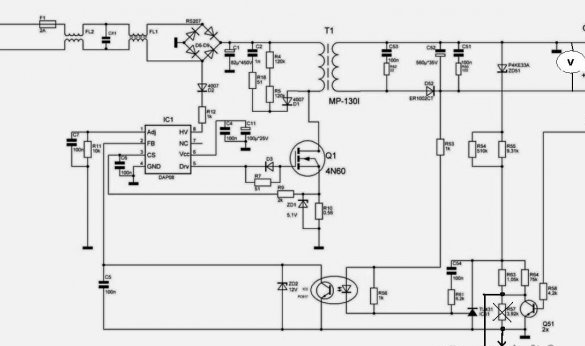

Consider the circuit of this switching power supply.

When the power supply is turned on at the SB terminal, we have a voltage of 7 V, and there is no voltage at the +24 terminal. If you need an unregulated voltage of 24 V, then you can connect the outputs SB and +24 to each other.

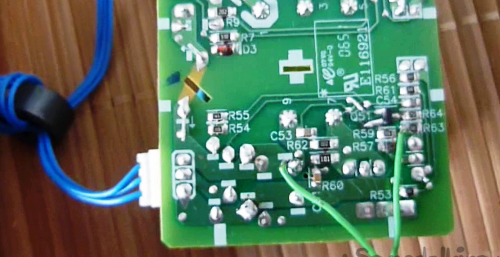

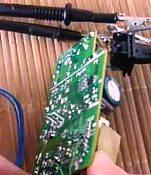

Our task is to regulate the controlled zener diode TL431. In the diagram, it is indicated as IC51. The controlled zener diode TL431 stabilizes the voltage at the output of the power supply depending on the load as it is included in the feedback circuit.We solder the resistor R57 on the board.

Instead, we connect a tuning multi-turn resistor with a nominal value of 5 to 10K.

Now the desired voltage can be set by rotating the axis of the tuning resistor. A multi-turn trimmer gives a smoother adjustment of the output voltage of the power supply.

We connect a minivoltmeter to the output of the converted power supply (in principle, any voltmeter can be connected, but there is simply not enough space in the standard case). I put an additional radiator from an aluminum strip on the diode assembly in order to reduce heating at maximum load currents. You can also drill in the vent holes.

We install the board in the native standard building (if desired, you can place it in a more spacious case, add output terminals). In the top cover we make a window for a voltmeter and an opening for a tuning resistor. The trimmer itself is glued with hot glue. On a rotary axis of the resistor we put a piece from the plastic rod (pre-smear with glue). Glue the cap from the tube onto the rod.

Step Two Checking the operation of the power supply.

After the alteration, I received the limits of the power supply regulation from 4.5 to 25 V. I connected the car lamp as a load. At a voltage of 5.8V, the current was 1.22A. At a voltage of 9.3 V, the current was 1.56 A. At a voltage of 24 V, the current was 2.2 A. It is an acceptable result.

As a result of a small alteration, they received a free compact adjustable power source. It can be used as a charger for smartphones, screwdrivers. Also power LED strips, homemade products - it all depends on your needs.

More alteration and pulse test from the printer can be seen in the video

I wish you all good health and good luck in your life and work!