Hello friends, radio amateurs and visitors to the site, sometimes when soldering boards and the like, it becomes necessary to hold the component to be soldered so that it does not move. And in order to facilitate soldering, I decided to show you how to make a "Third Hand" for soldering various boards and microcircuits. The clamps of this "Third Hand" are made of plastic, which makes them dielectric. The "third hand" will be fixed on the base of the fiberboard to which it will be possible to attach different fixtures for soldering, such as: a soldering iron holder, a coil with solder, a backlight, a magnifying glass, well, and many others that you want to attach. The advantages of this design of the "Third Hand" are: ease of manufacture; available materials; The clamps will be made of plastic, which is necessary when soldering circuits with voltage.

- Sheet steel with a thickness of 3 - 3.5 mm

- Bulgarian (UShM)

- Drill or drilling machine

- Hairpin M8 100 mm long

- M8 hairpin 60 mm long

- M8 nuts

- Welding machine

- M4 bolts

- M4 nuts

- Sheet steel 2 mm thick

- Small plastic clips (purchased at the nearest store)

- 25 mm screws

- Drill

Well, let's get started, take these M8 studs, the length of the first 100 mm, the second 60 mm and the nuts to them.

Next, we take from sheet steel with a thickness of about 3 - 3.5 mm using a grinder we cut out such workpieces with the dimensions: Two of them 17 * 20 mm, and the third 17 * 23 mm.

As the next step, we take a nut on a hairpin 100 mm long and weld the workpieces along the edges whose dimensions are 17 * 20 mm, squeezing the third workpiece between them (it does not need to be welded!)

After we welded the workpieces, we check them so that they are welded evenly. Next, take a 4 mm drill and drill all three workpieces in the center.

After the hole has been drilled, we take it to the plate, which more accurately welds the short hairpin. You need to weld evenly.

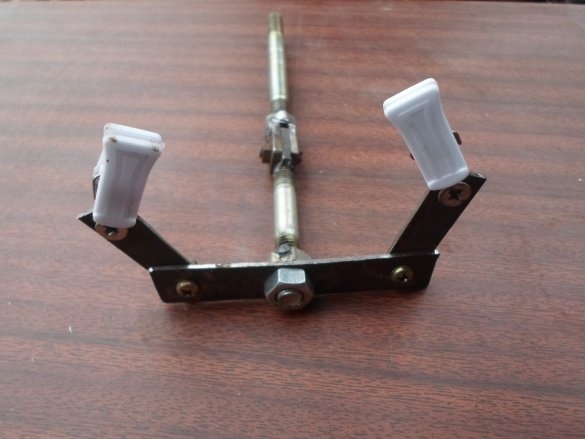

After we have welded everything, we take the resulting workpieces and connect them with an M4 bolt. We check that the workpieces can freely move relative to another workpiece, if everything moves, then we move on, if not, then we grind the corners of the workpiece with a short hairpin.

We take sheet steel approximately 2 mm thick and cut a strip 20 mm wide, the length of this strip can vary, depending on how long you will clamp the piece to be soldered.

We drill holes, in the center it is necessary to drill a hole by 8 mm, and along the edges 4 mm.

The next step, clamp the workpiece between the nuts on a short hairpin. The lower nut will need to grab a little welding machine, this is necessary for the convenience of tightening.

Next, from the same steel with a thickness of 2 mm, we cut out two such workpieces, the dimensions of which are 20 * 45 mm, we tilt and drill holes 4 mm

We fasten the resulting workpieces to the main part with M4 bolts

After that I went to the store and bought two of these plastic crocodiles with two metal eyelets

The loops had to be squeezed a little with pliers

We fix the crocodiles to the main part with M4 bolts

The third hand is almost ready, it remains just to secure it. For the convenience of work, I decided to take a larger site. For the manufacture of the site, a fiberboard sheet with dimensions 50 * 40 cm and a thickness of 2 cm was used.

To fix the third hand, we take a step back from the edge of 7 - 8 cm and drill a hole of 8 mm, on the other hand we expand the hole to 20 mm, this is necessary so that the nut enters the tree

So that the third hand does not fall into the fiberboard sheet to its base, stepping back about 2 cm, weld the washer.

We fasten the third hand to the base.

I decided to make a stand for a soldering iron. And just cut it out of wood with a jigsaw.

We fix the stand with screws, as you can see the soldering iron is not bad.

Well, all our "Third Hand" is ready!

You can improve the design as you wish.