In this article, Ben, author of Ben's Worx YouTube channel, will tell you about how he turned a boring screwdriver handle into a very interesting, and at first glance, a bit dangerous.

Similar article About the handle from the sleeves was earlier, but this master uses a slightly different filling technique.

Materials

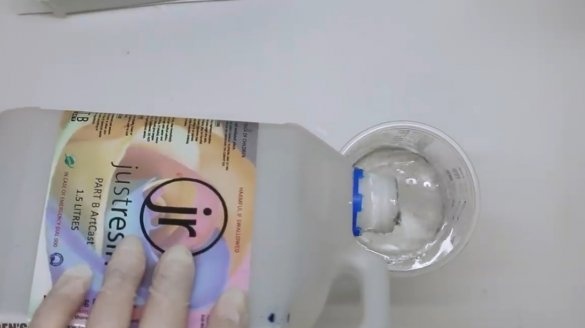

- Two-component epoxy resin

- Sandpaper

- Abrasive polishing paste

- screwdriver

- masking tape

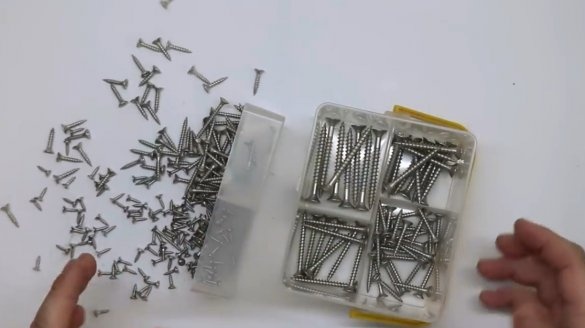

- Self-tapping screws, or cogs.

Instruments, used by the author.

- Lathe

- Chisels

- Glue gun.

Manufacturing process.

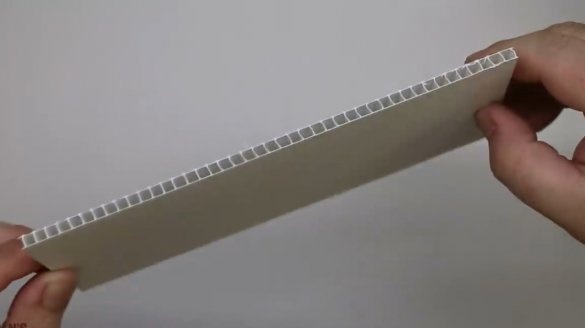

So, the author scored a few screws, a screwdriver with a not very aesthetic handle, and plastic for formwork.

He will also use such a two-component epoxy resin.

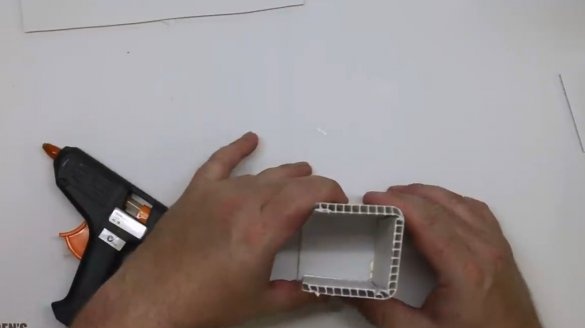

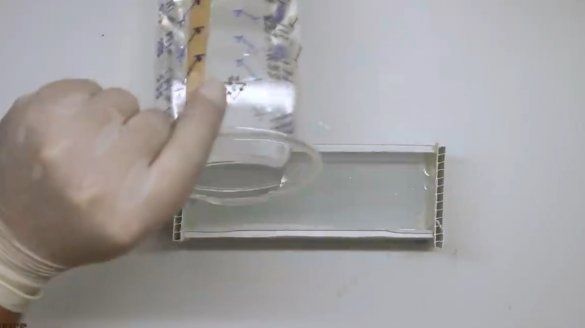

Then, using a glue gun, he makes the formwork. Before pouring its edges, it is desirable to process with a separator, for ease of disassembly, but the author decides not to. After the resin hardens, it simply breaks the plastic.

Mixes both components of epoxy resin, and fills a third of the height of the future shape. This is necessary so that the screws remain inside the handle, and not protrude beyond it.

The next day, after the first layer has hardened, spreads the screws on it, and fills the second layer twice as thick as the first. Then it collects all the screws in the central part, and leaves it for another day.

Secures the workpiece to a lathe, and begins processing. First aligns it to a cylindrical shape. At all stages of turning operations, it is extremely important not to overheat the workpiece. Epoxy resin when overheated loses its strength, becomes brittle. And individual brands of resins can change color and turn yellow.

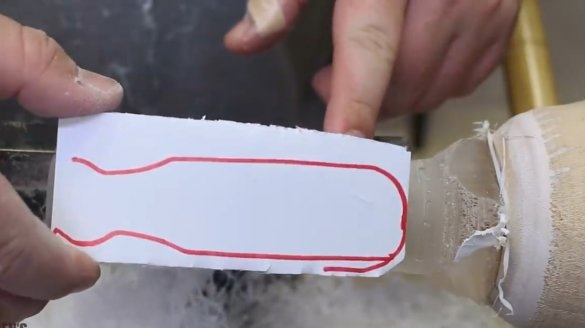

After that, you can already set the handle the desired profile.

A chip has formed at the bottom end of the workpiece, it will have to be grinded and the upper part of the handle incised.

The following is the grinding step, starting with sandpaper P100, and up to P600.Final sanding is done with water added with P1000 paper.

Now the stage of polishing with abrasive paste. In the former Soviet Union, GOI paste is used.

It remains only to drill a hole for a screwdriver.

And, having protected the finished handle with masking tape, glue a screwdriver into it.

That's all, it turns out a very unusual handle on a screwdriver.

Thanks to the author for a simple but interesting way to improve the appearance of the tool!

All good mood, good luck, and interesting ideas!