Everything has its own term. Here are the master’s beds, the time has also come to go to the scrap. Accordingly, the question arose about a new bed. The master had a board and he decided to make a bed himself. But not just a bed, the bed should be under the mattress 2000 * 1800.

Tools and materials:

-A circular saw;

-Hacksaw;

- Hacksaw for metal;

-Circular Saw;

- Chisels;

-Calipers;

-Roulette;

-Rule;

-Pencil;

Grinding machine;

- Orbital sander;

- Planing machine;

-Plane;

- Cordless and electric drill;

- Socket wrench;

-Screwdriver;

-Drilling machine;

-Drills (conventional, Forstner, fountain)

- Clamps;

Milling cutter;

-Various grinding accessories;

- Oak railway sleepers 100 x 200 x 2400 mm - 2 pcs;

- Elm boards;

- Walnut boards;

- Pine board 40 x 40 x 2400 mm;

-OSB 11 x 1200 x 2400 mm;

- dowels;

-6 mm threaded rod;

-Nuts with 6mm thread;

- Joiner's glue;

- Danish oil;

Step One: Preparing an Oak Board

The main bed frame is made of oak. Oak plank is expensive and the master bought old railway oak sleepers. Sleepers weigh about 60 kg, and for further processing it was necessary to first saw them in half, and then make blanks in size. The width of the saw blade was not enough to cut the entire thickness, and the master made a cut from two sides. In total, the master needed four beams of 100 mm x 100 mm x 2400 mm.

Now you need to round off the workpiece. Oak - solid wood, and the master had to torment with planing.

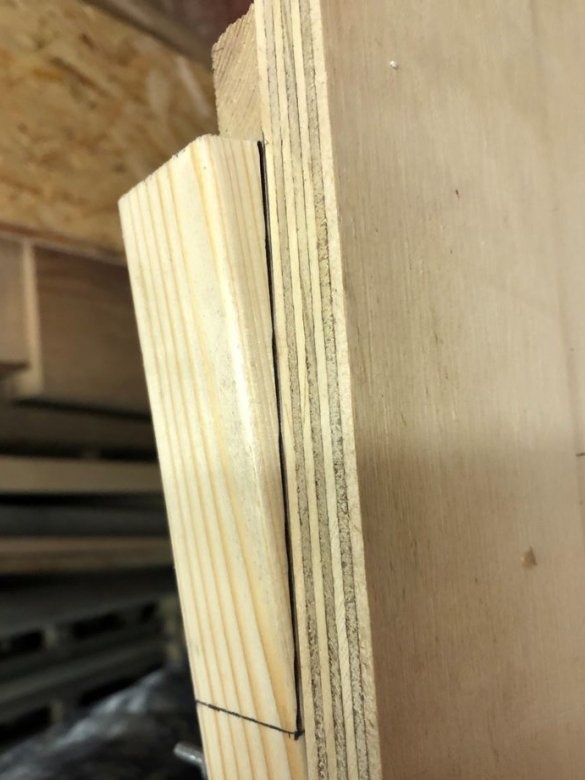

Step Two: Connect

Now you need to prepare the frame joints. Joining a master is a classic angular joint in half a tree. The length of such a connection is equal to the width of the fastened workpieces and is equal in height to half the height of the workpiece. Makes markings at the ends of beams. Hacksaw makes cuts to the desired depth (immediately saws off the beams to the desired length). Breaks out wood. Grinds the junction. Such an operation is carried out at each end of each beam.

Step Three: Frame Connection

Connects the frame and checks the joints. Makes butt joints.Joints must fit snugly together. Grinds beams.

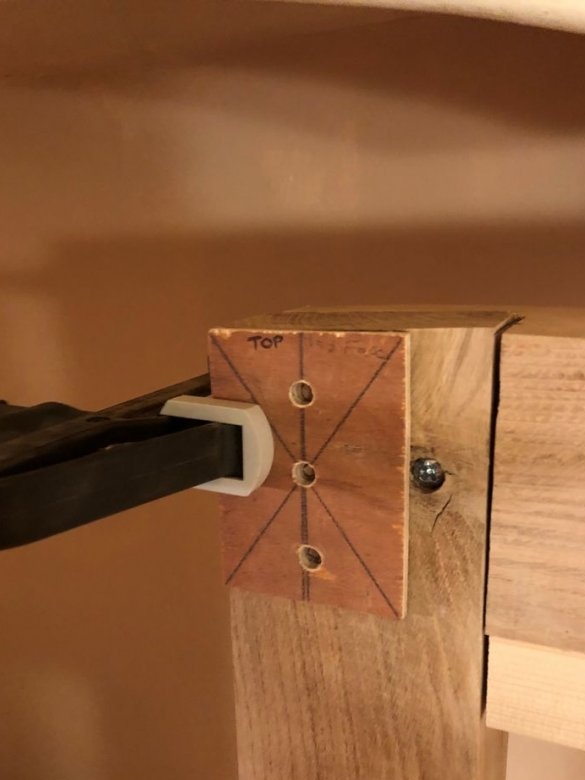

The beams will connect using bolts. First, the master made a template - a square with a markup.

Drills holes according to the pattern. Installs threaded inserts in the holes. It connects the beams and fixes them with bolts. Saw off protruding material.

Step Four: Feet

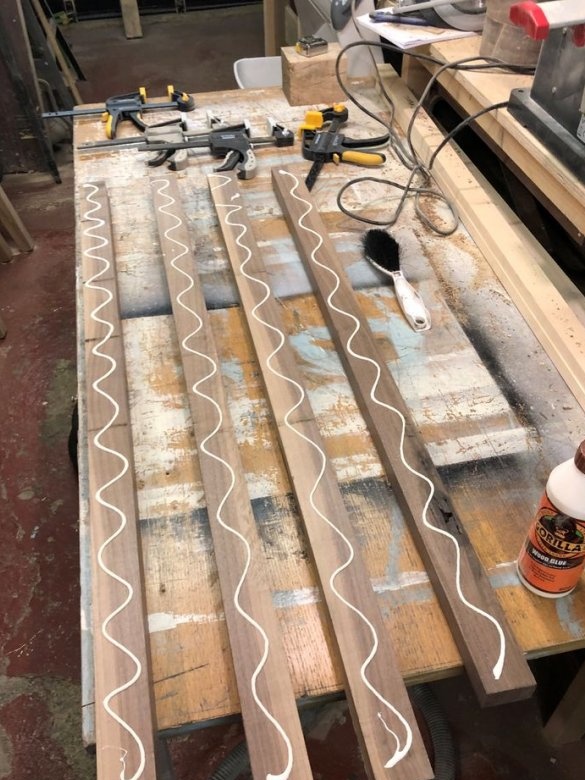

The legs are made of walnut. The master acquired four walnuts. Scolded them. Glued together. He scolded again.

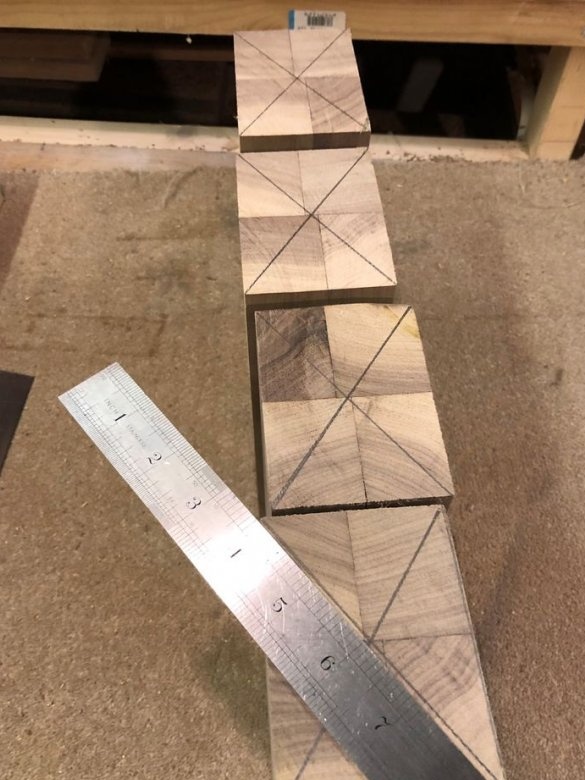

Now the workpiece needs to be cut into four equal parts.

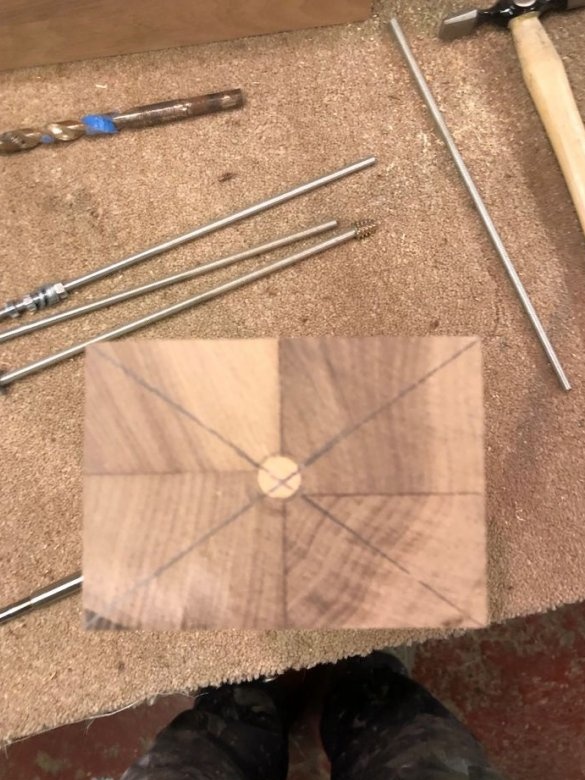

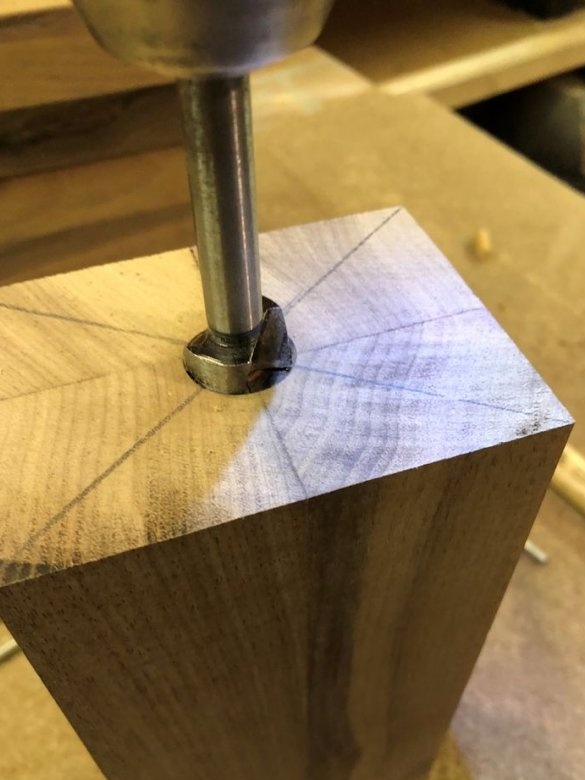

The legs will be attached with studs and dowels. Marks the centers of the blanks. Drills a through hole. Drills holes for dowels. Bottom legs drill holes for nuts and washers.

Step Five: Installing the Feet

Makes a pattern. According to the template, drills holes in the corners of the frame. Installs dowels and threaded rods. Screws the legs.

Step Six: Mattress Support

Modern mattresses are laid either on slats or on a rigid base installed inside the frame. The master decided to stop on a tight basis. Secures the inside of the frame wooden blocks around the perimeter and two in the middle, at an equal distance from each other. Parts of the frame are reinforced with a metal corner.

Slices four pieces of OSV for the entire length of the bed. The frame is reinforced with corners and the master makes cuts on two OSV sheets. Now it remains to lay the sheets and fasten to the bars.

Seventh step: headboard mount

The head of the bed is made of a single piece of elm with a thickness of about 20 mm. The master will fix the headboard to the frame using four cylindrical blanks (dowels) with a diameter of 38 mm and a length of 350 mm. Two at the edges and two in the middle. Marks the installation location of dowels. Drill holes for the diameter of the dowel. At the end of the dowels, drills holes and installs a threaded insert. Installs the dowels and bolts them from the bottom.

Step Eight: Headboard

Cuts the workpiece to size.

Now you need to position the headboard so that it does not interfere with the mattress. To do this, the master makes a template in height equal to the height of the mattress. Makes a mark on the dowels.

The headboard will be fixed at a slight angle. To do this, gash it at an angle of the dowel. The master makes a template and according to the template saws off the dowels from the mark to the top.

Now, in places of fastening, it is necessary to install threaded inserts.

Step Nine: Sanding and Coating

After all the preparatory work, the master dismantles the bed and cleans, and polishes the details.

Covers all parts of the bed with Danish oil. It polishes. Assembles the bed completely.

The bed is ready and it remains only to install a mattress.