In this article, the Wizard will tell us how to make an ordinary bicycle bike on electric traction. Moreover, the master uses a gear motor from the sliding door mechanism as an engine. The master found a motor in a pile of scrap metal. This brush motor is small in size, powered by 42 V DC and has great torque.

So, for the manufacture of such a bicycle, we need the following

Tools and materials:

-Motor reducer;

-Bike;

-18650 lithium-ion batteries;

-Electronic speed controller (ESC);

-Wire;

-Connectors;

-Gear;

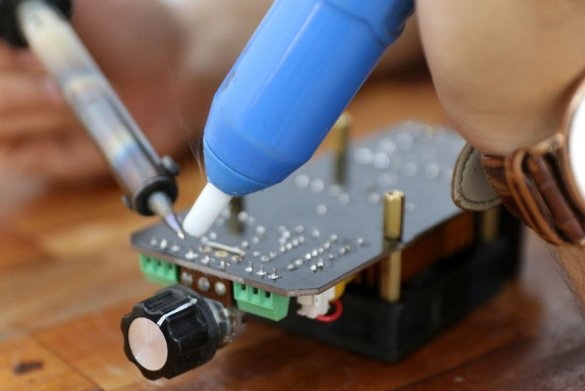

-Soldering accessories;

-Nippers;

-Drilling machine;

-USHM;

-Clamp;

-Welding machine;

-Acrylic;

-Aerosol spray can with paint;

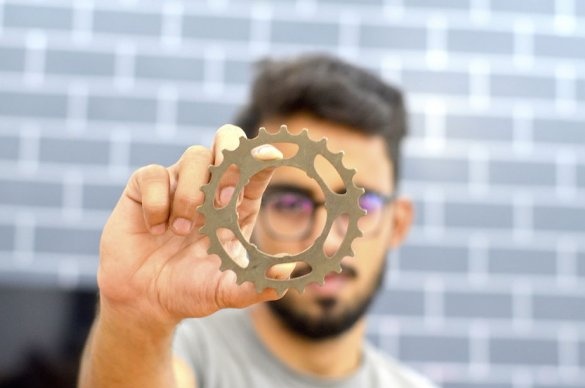

Step One: Driven Sprocket

To transfer traction from the engine to the rear wheel, the master remakes the sprocket.

Parses the mechanism of the rear wheel.

For further work, you need an asterisk for 21 teeth, a brake disc and a spacer from the pipe.

You need to weld an asterisk to the disk through a spacer. Cleans weldable surfaces. Clamps with a clamp and welds.

He covers the disk with paper and paints an asterisk.

Mounts the mechanism on the wheel.

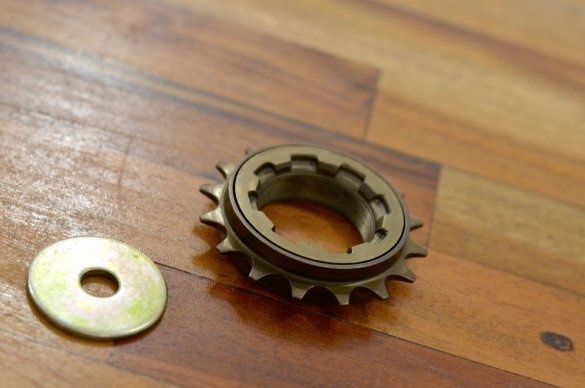

Step Two: Installing the Gear on the Engine

Now you need to install the drive gear on the engine. The master uses the gear with an overrunning clutch. Welds the washer to the gear mechanism.

Drills mounting holes and fastens the gear to the engine gear.

Step Three: Engine Installation

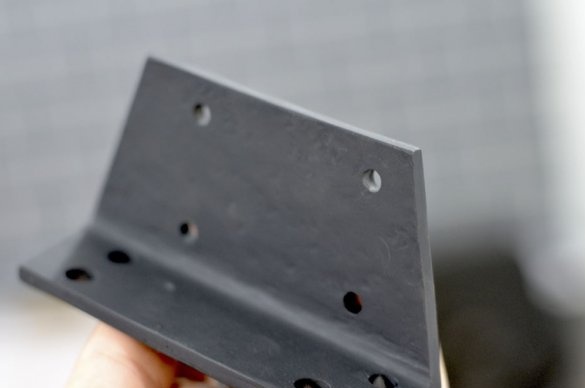

First, the master, using a template, finds the optimal engine location and mounting form.

Then, using a template, makes a mount from a metal corner. Drills mounting holes, paints, fastens the mount to the motor.

Screws the engine to the frame. Puts on a chain.

Step Four: Batteries

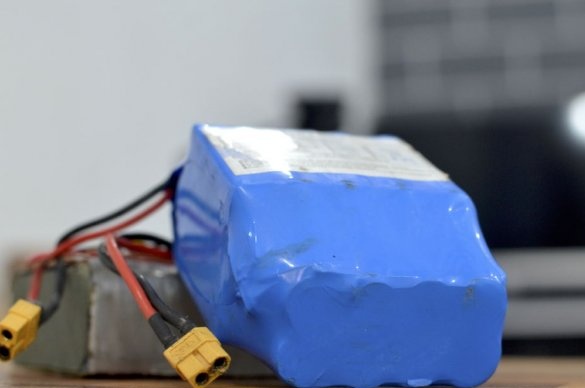

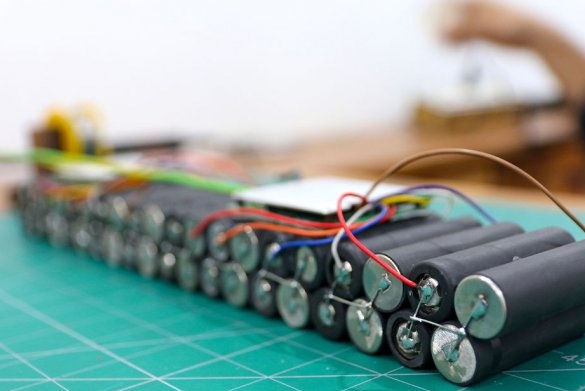

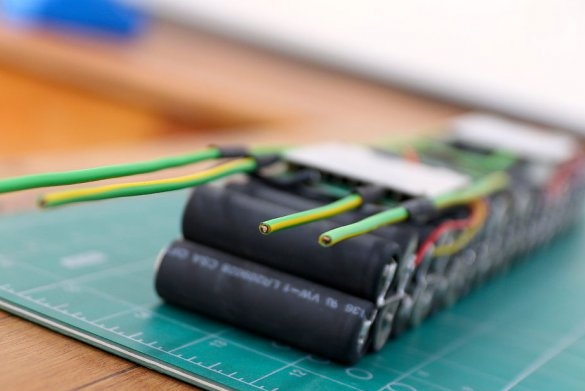

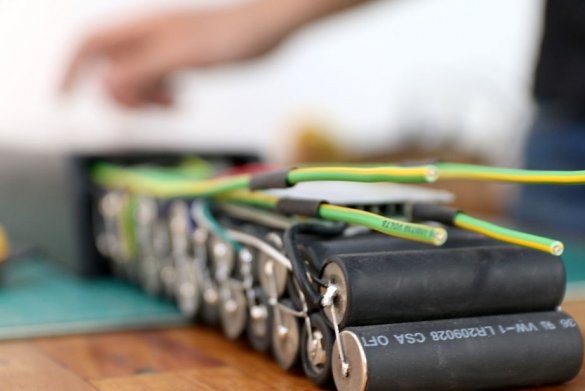

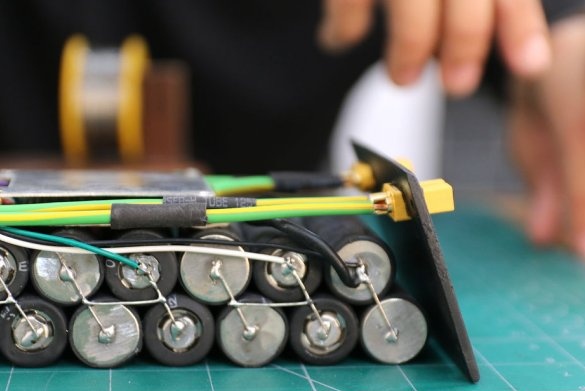

The master uses lithium-ion batteries of the 18650 form factor as an energy source. The batteries were removed from an old skateboard.To power the motor of an electric bike, the master plans to use two blocks of twenty batteries each.

To install the batteries, the master uses a serial-parallel connection.

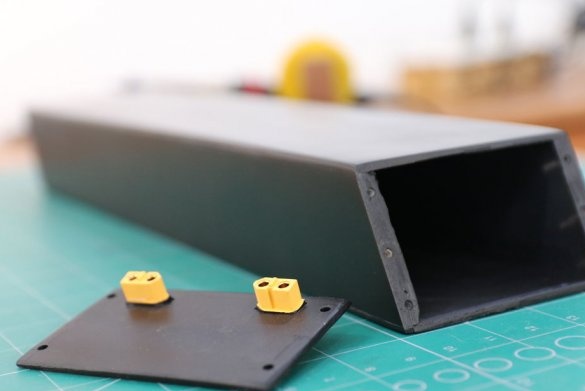

Step Five: Case

For batteries, the master makes an acrylic case. Cut acrylic in size. Glued together. Painted in black.

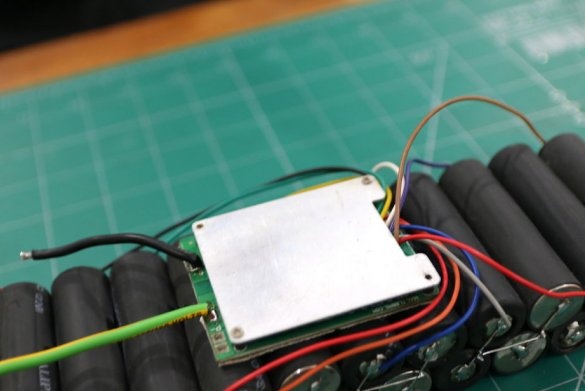

Installed in the battery case. I fixed two XT-60 connectors on the housing cover. Connected the battery leads to the connectors.

Secured the battery compartment on the bike frame.

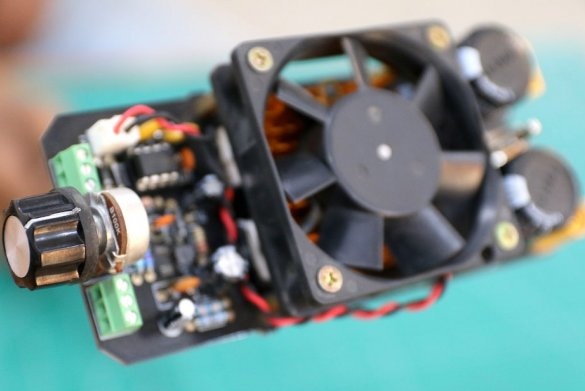

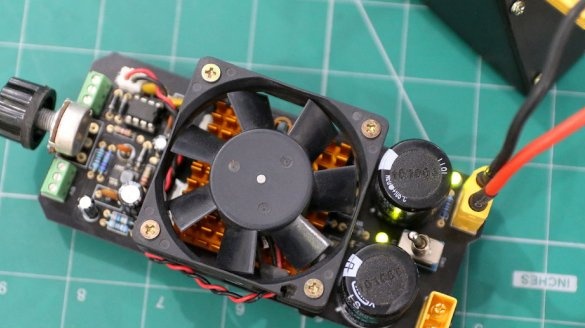

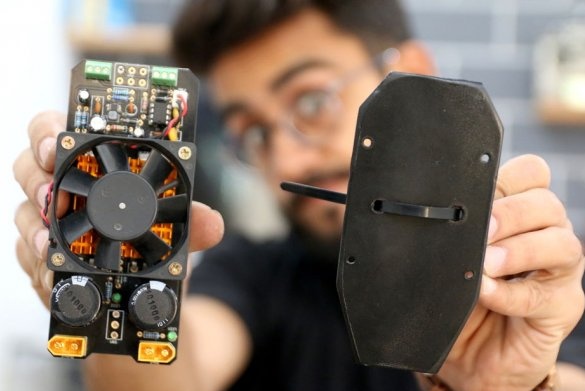

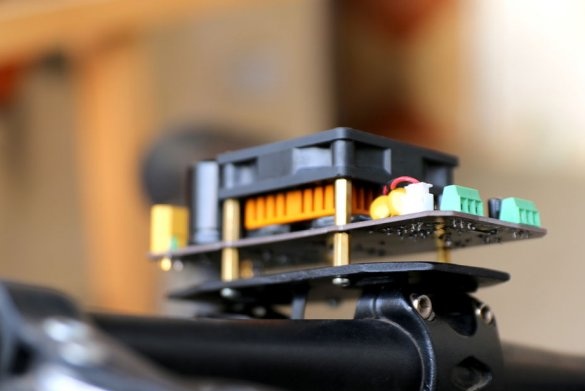

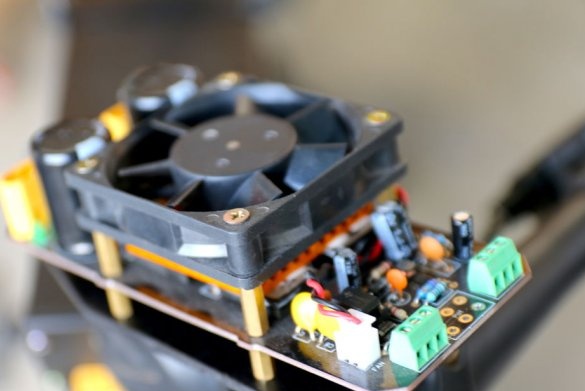

Step Six: Controller

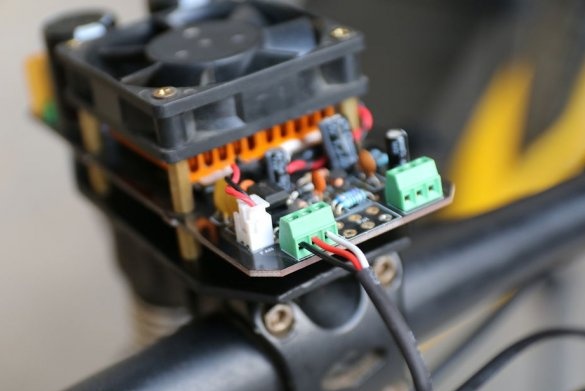

To control the speed of an electric bicycle, the author decided to use a PWM speed controller with an adjustment range of 5 V-84 V DC. The master made such a controller, you can see by clicking on the link

Attaches the controller to the mounting plate. Then, using the clamp on the handlebars of the bike.

Connects the throttle stick.

Mounts connection to battery and motor.

Everything is ready, it remains to check the electric bike at work.

According to the master, acceleration is smooth and the maximum speed developed by an electric bike is 30 km / h.

The whole process of converting a bicycle to electric traction can be seen in the video.