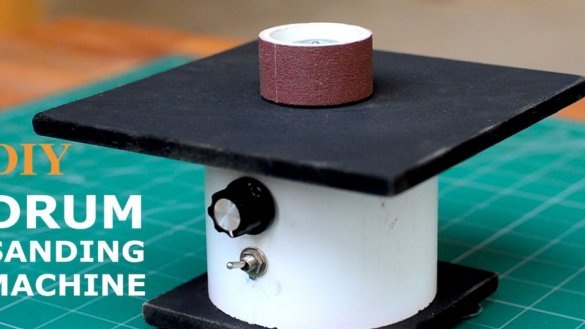

This grinding machine has a silent engine running on lithium-ion batteries, interchangeable grinding drums and speed control. According to the master grinding machine is designed to work with different materials, such as plywood, MDF, acrylic, aluminum.

For the manufacture of the machine, the master used the following

Tools and materials:

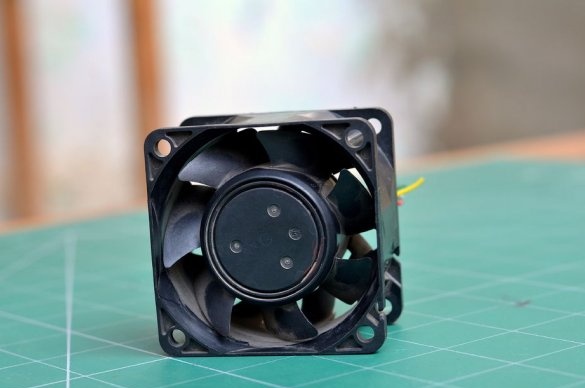

-12V fan;

-3 "PVC pipe;

-Lithium-ion batteries;

-5 mm MDF sheet;

-BMS;

-Tumbler;

-Connector;

PWM;

-Drill;

-Drill;

-Wire;

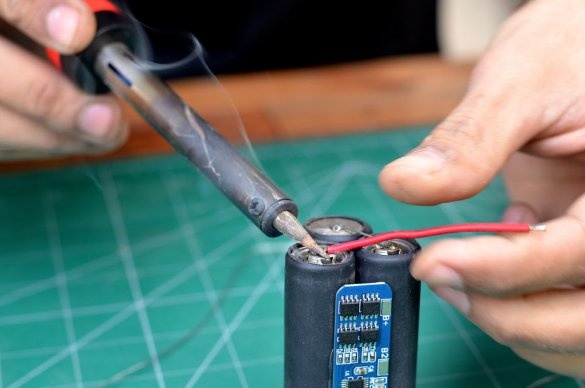

-Soldering accessories;

-Pliers;

-Screwdriver;

-Fasteners;

Step One: Installing the Engine

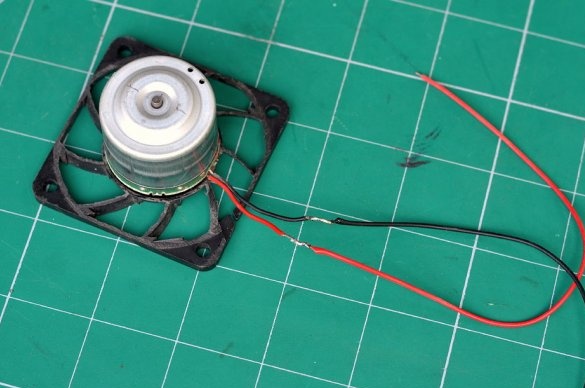

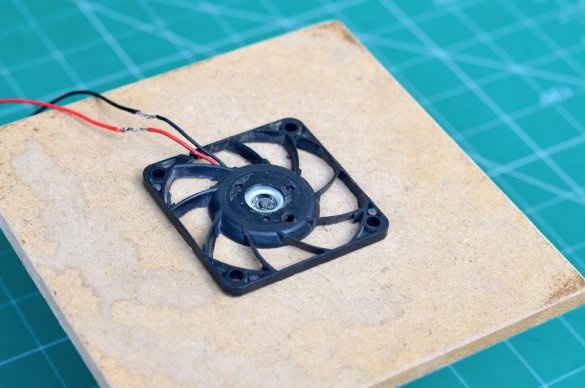

Before mounting the engine, it is necessary to remove part of the fan casing and blades.

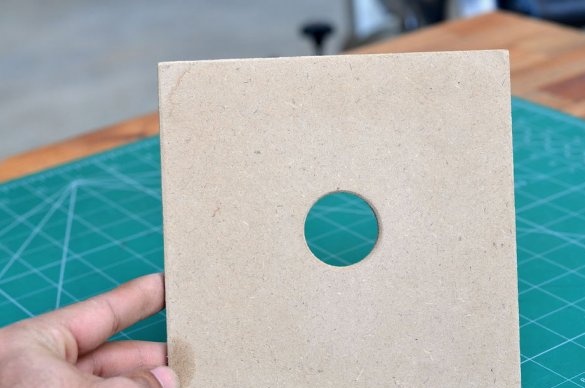

Further in the center of the MDF sheet, a hole slightly larger than the diameter of the engine is cut.

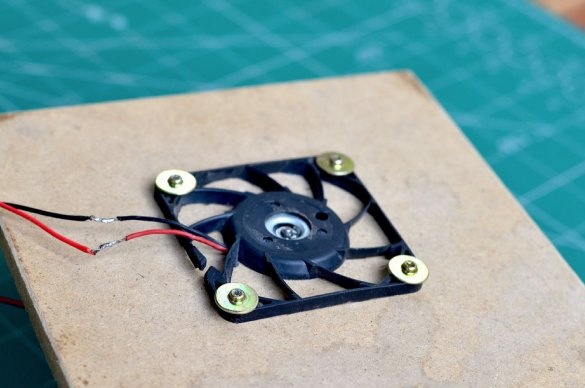

Installs the motor in the holes and fixes the plastic housing with screws.

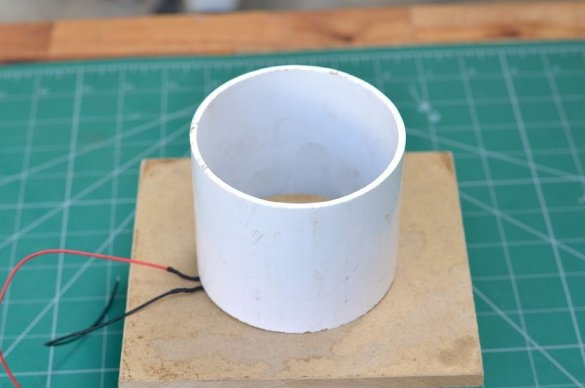

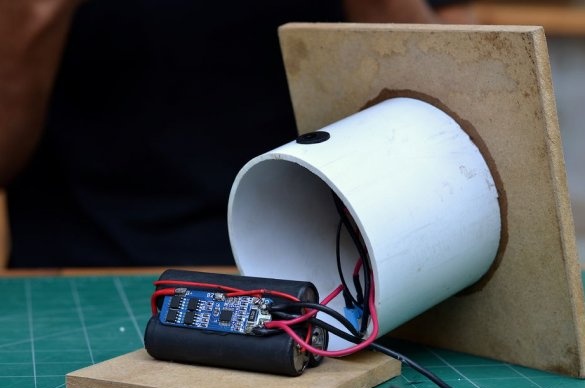

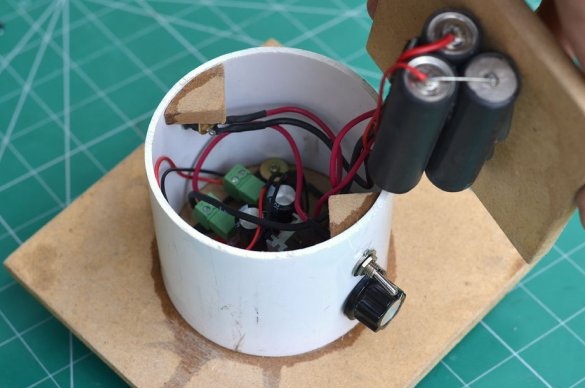

A piece of PVC pipe is glued on top of the body. It will be installed electronics.

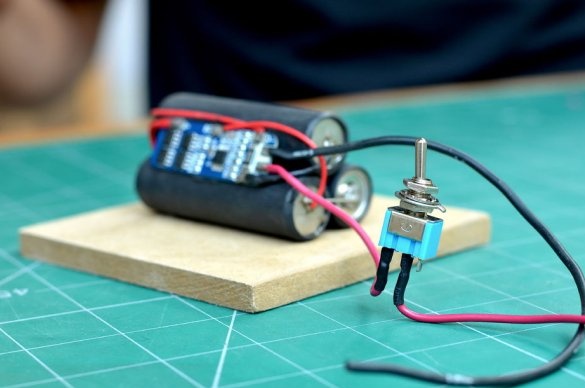

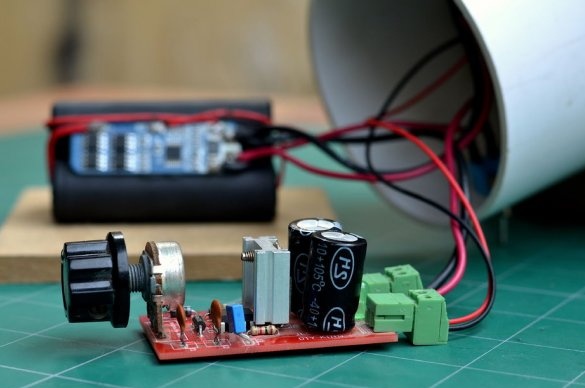

Step Two: Batteries

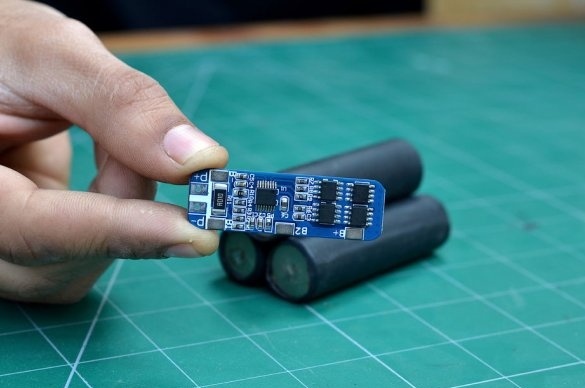

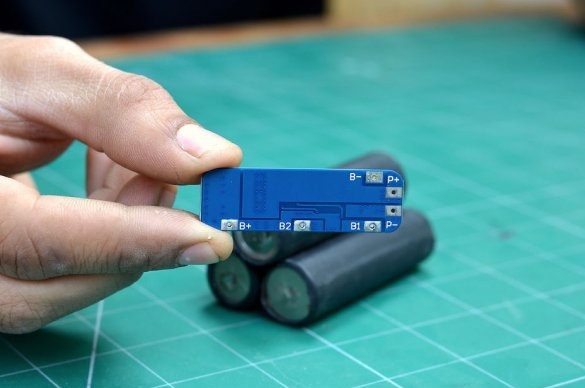

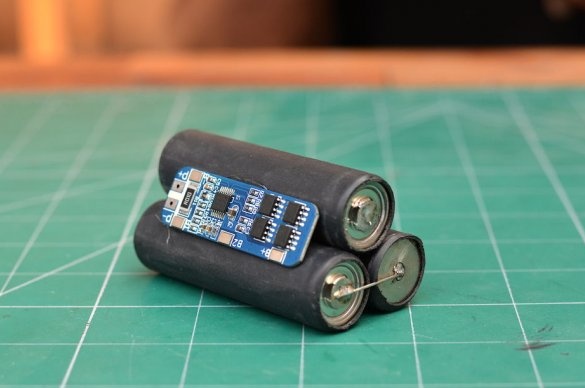

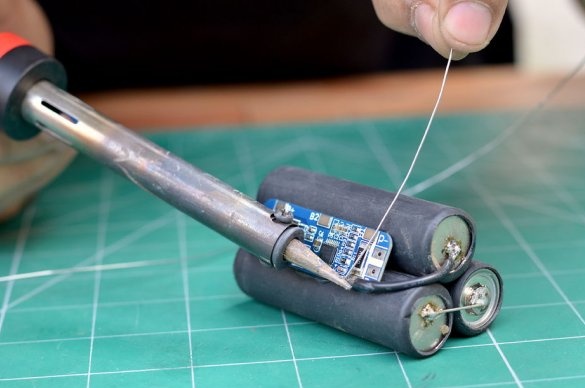

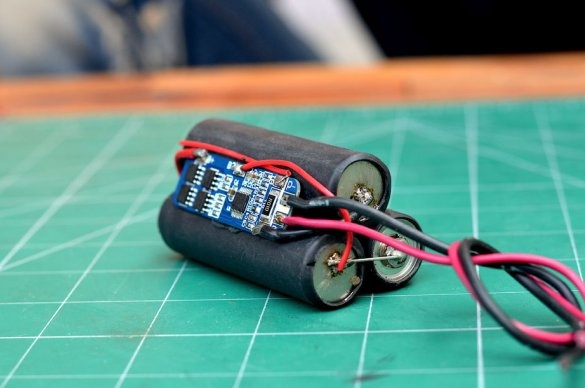

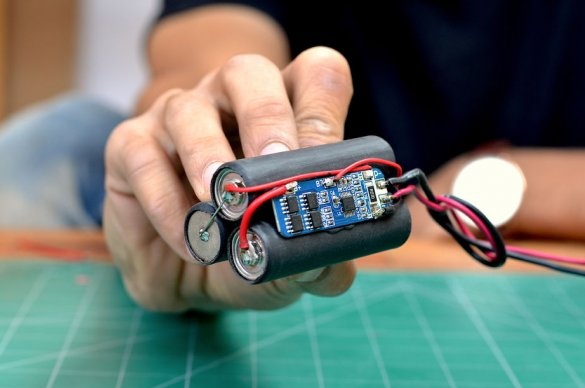

To power the machine, the master uses three 18650 lithium-ion cells extracted from an old laptop battery. The batteries are connected according to the 1P 3S scheme, then the BMS battery management system is mounted.

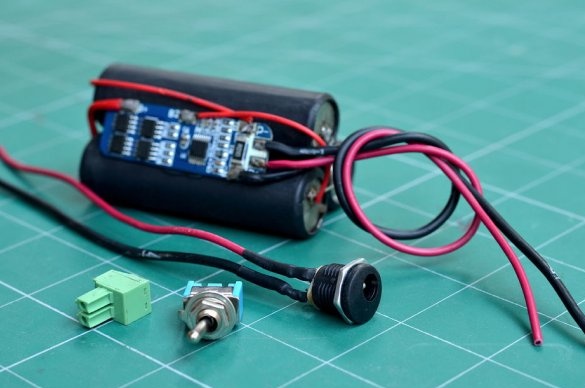

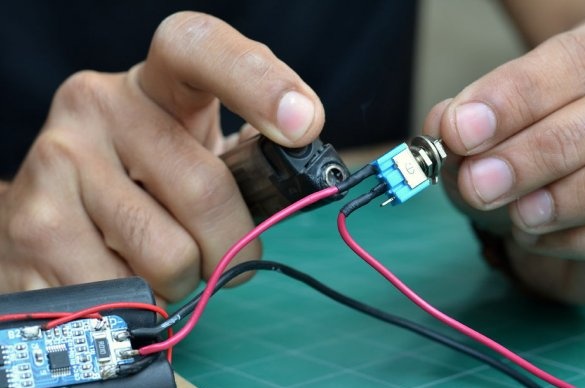

Step Three: Button and Charge Connector

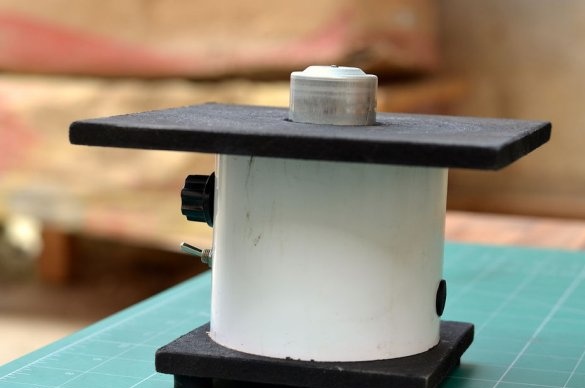

To turn on the machine, the master installed a toggle switch, and a connector for charging the batteries.

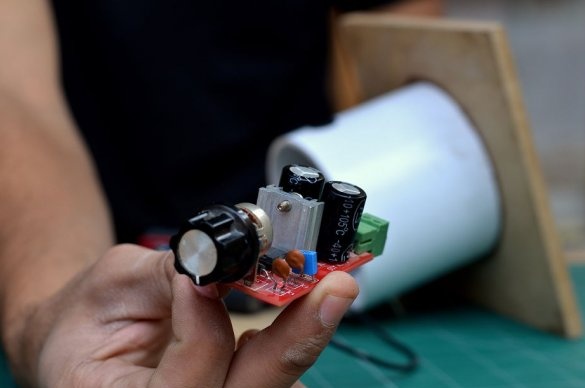

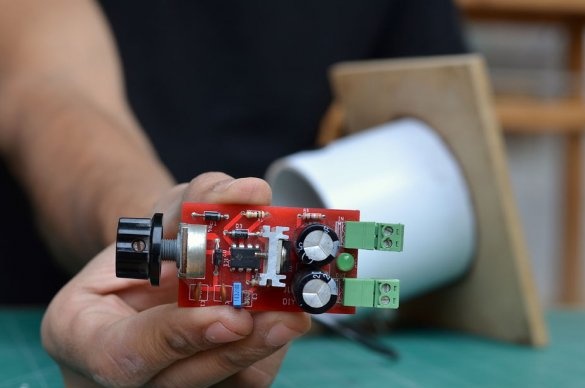

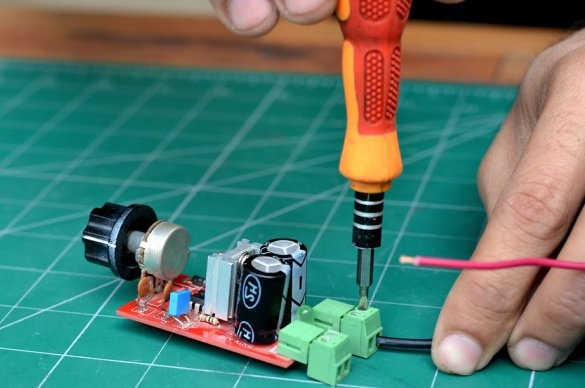

Step Four: PWM Controller

The controller is needed to adjust the speed of rotation. The master ordered the controller board on one of the specialized sites. By the linkYou can download the diagram and parts list.

Also, the master inserted a video explaining the manufacturing procedure of the PWM controller.

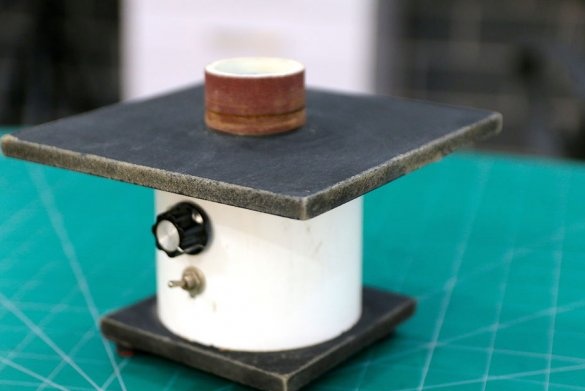

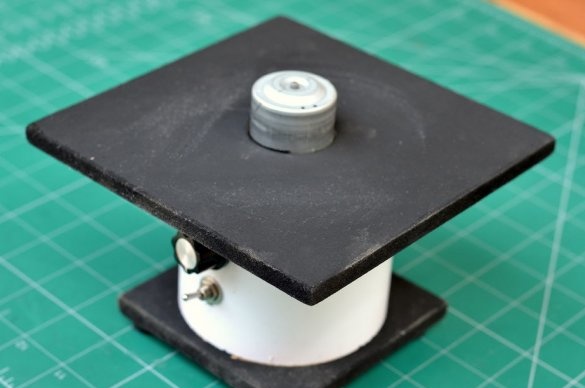

The batteries are connected to the controller input, and the engine is connected to the output. The controller is installed in the housing. On top of the case is a square base made of MDF. In the corners of the base, the master glued anti-slip legs.

Step Five: Painting

It covers the body and engine with a bag and stains MDF.

Step Six: Grinding Drums

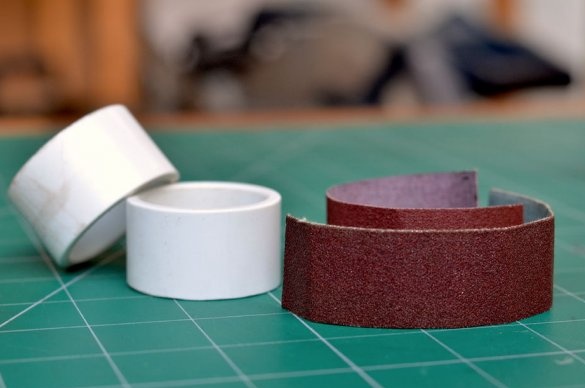

The master picked up the PVC pipe so that it fit snugly onto the engine. I cut it into several parts.I glued strips of sandpaper of different grain sizes around the circumference of the segments.

Next, you need to install the grinding drum on the engine and you can begin the tests.

The whole process of manufacturing such a small grinding machine can be seen in the video below.