Surely masters use knives for various types of work.

In this article, YouTube author of Young Je tells you how he made a simple carpentry knife from an old saw blade.

Materials

- Old saw blade

- Rosewood Brusochek

- Brass bar 4 mm in diameter

-

- Set of sandpaper

- Oil

- Two-component epoxy resin

- Spray paint

- Double-sided tape.

Instruments, used by the author.

-

- Drilling machine

-

-

-

-

- Belt sander

- Patterns, core, ruler.

Manufacturing process.

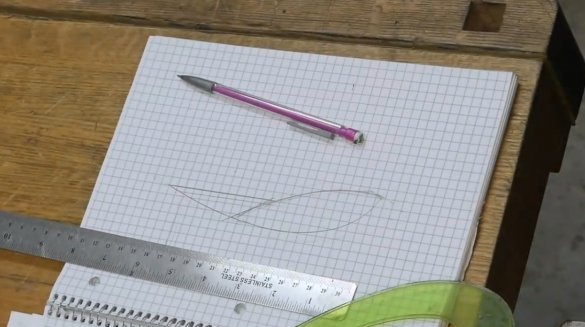

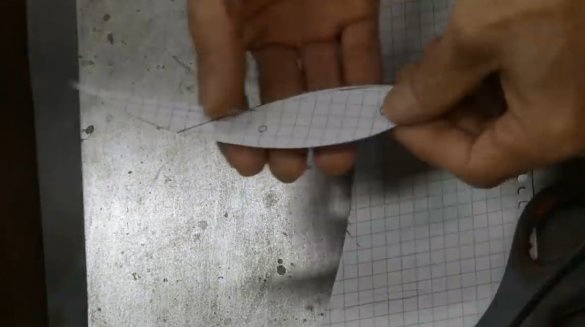

First of all, the author marks out the shape of the blade itself, for this he drew and cut out a template.

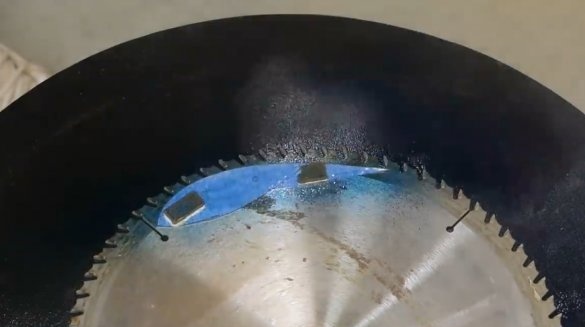

Then he fixed the template on the disk with magnets, and applied a small layer of paint, getting the outline of the template. I cut the workpiece with a grinder.

Then he smooths all the edges on the tape machine, with a coarse tape, then a shallow one.

To simplify the further processing of the metal, it anneals the workpiece.

He paints the workpiece again, marks the slopes, and corns the rivets.

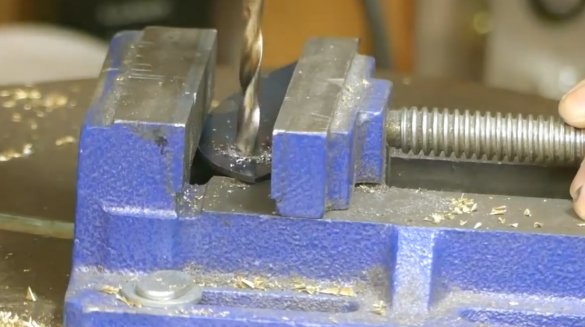

Drills holes for rivets on the machine with a 4 mm drill.

To form the descent of the blade, the master uses a block with a slope of one face by 15 degrees. It fixes the workpiece on it and processes it on a tape machine.

Now the manual processing of the blade begins. It processes with emery paper up to 360 grit.

Then cleans the surface of the workpiece from paint.

And it hardens the blade. It can be performed even without special measuring instruments. It is enough to heat the blade until the moment when it ceases to magnetize. This means that the Curie point is passed, and it can be lowered into the oil, stirring constantly.

After checking the blade for hardness and descaling, the author proceeds to the last stage. Leave the workpiece. This technique allows you to reduce the fragility of the metal, as well as give elasticity. To do this, the master placed the workpiece in the oven, preheated to 190 degrees. The blade must be heated for 60 - 90 minutes, and then turn off the oven, and allow to cool to room temperature.

This is followed by final sanding with water. The last grit on which the author decided to dwell is 1500.

The master proceeds to manufacture the handle from the rosewood, and cuts two blanks on a band saw. Connects them with double-sided tape.

Now processes the edges of the blanks on the band saw.

He transfers the marking for rivets from the blade to the workpiece, drills holes.

Two rivets are cut from a brass 4 mm bar.

Clogs rivets in the first part of the handle. Then, using a two-component resin to connect the parts, collects them. For a tighter connection Tap with a hammer through the lining.

Pulls the handle with clamps and leaves to dry.

Now the final processing of the handle on the band saw. The author gives her an oval shape.

At the base of the heel, removes residual epoxy and polishes.

Now follows the final grinding of the handle.

And the final polishing of the blade on a leather disc.

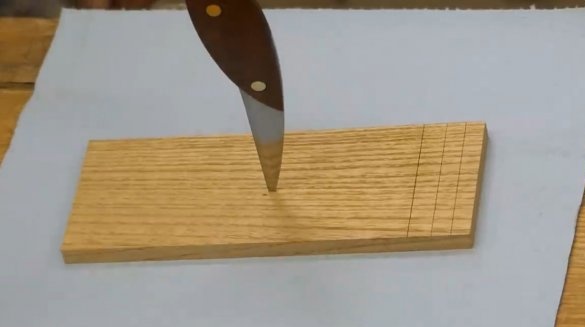

The knife is almost ready, cuts the tree as it should.

It is also perfect for marking wooden blanks.

The master has to make the final touch - soak the handle with linseed oil.

That's all, it turned out a very beautiful tool for a joiner and not only!

Thanks to the author for the unusual idea of a carpentry knife!

All good mood, good luck, and interesting ideas!