Hello Dear readers of the site and the inhabitants of our site!

Today we will consider a very interesting screwdriver tip. This homemade product allows you to pull out nails with a screwdriver. This is essentially an electric nail clipper. Progress does not stand still and many friends come up with different fixtureshow to ease your work. Consider the invention in more detail. The following tools and materials will be required to make this nozzle.

Step One: Tools and Materials

Instruments:

- Bulgarian;

- Welding machine;

- drill;

Materials:

- Round metal pipe with a diameter of 20 mm. and 25 cm long;

- A piece of a corner;

- The extended nut with a diameter of 10 mm;

- A hairpin with a diameter of 10 mm;

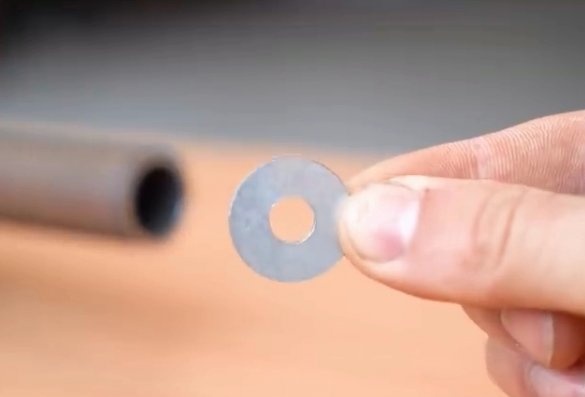

- Washer with an outer diameter of 20 mm;

- Nut 10 mm. - 4 things.;

Step Two: Cylinder Fabrication

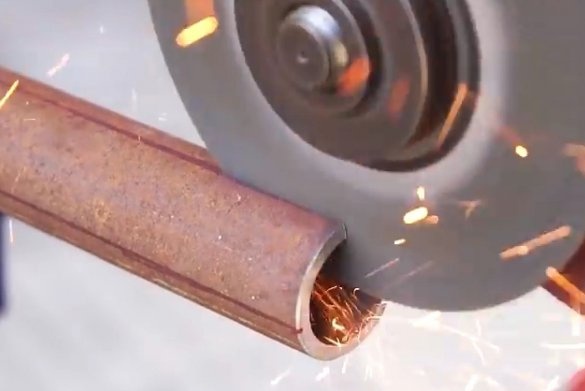

To make a cylinder, the master takes a metal pipe and, using a grinder, cuts a groove in it, 15 cm long and 2 cm wide.

The edges are treated with a grinding nozzle on a drill.

On the other side of the metal pipe, the master welds the washer.

The master grinds the edges from welding with a grinder.

After that, the hole in the washer, using a drill, the master increases to a diameter of 10 mm.

Step Three: Capture Making

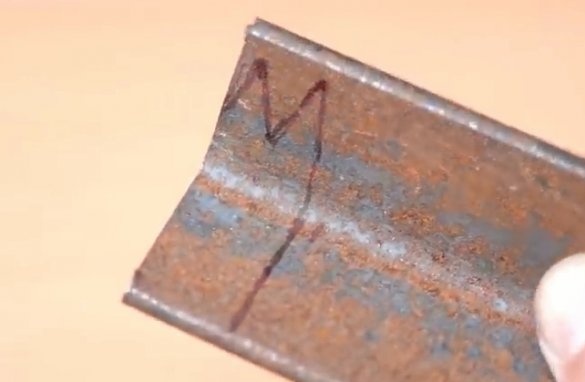

From the corner, the master cuts off a part 2 cm wide.

On one side of the part carves a fork.

The author welds an elongated nut to this blank.

Then the master polishes the resulting part.

Shanks the inside of the fork at an angle.

Step Four: Assembling the Fixture

A two-prong is screwed onto the hairpin, which will tear off the nails.

Then two nuts are screwed onto the stud and the stud is inserted into the cylinder.

On the other side of the cylinder, the stud is also fixed with two nuts.

Step Five: Testing

The master inserts the free end of the stud into the screwdriver.

When you turn on the screwdriver, the stud begins to tighten the elongated nut with a fork.

As a matter of fact, in this way, nails should be pulled.

Step Six: Conclusions

For me, this device has no practical value. I can’t believe that it works.But I’m pretty sure that with nails> 70 mm it won’t work, in new wood and especially hard wood. I think, at the beginning of the device, a quality support bearing, like on diamond-shaped jacks, will not hurt. And the stud itself, probably, should be made of high-strength steel and always with a small thread pitch. Then it will last longer and it will be easier for the screwdriver and it won’t burn out right away.In addition, it’s not very clear how to put this plug under the nail. You can even hit the nail gun with a hammer.

The process of manufacturing this attachment to a screwdriver you can watch on video: