Greetings to lovers of craftsmen, spring has already come, which means that soon grass will be actively climbing, which will need to be mowed. Nice to do this without much effort will allow the lawn mower. You can make such a useful tool do it yourselfif you have a motor from the washing machine. Of course, the power of such a machine will be small enough to mow the jungle on the chest, but you can always trim the grass. Homemade easy to assemble and does not require expensive materials. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- the engine from the old washing machine (better more powerful);

- iron corners;

- bolts with nuts;

- profile pipe;

- iron plates;

- 3 castors for trolleys;

- round timber;

- a sheet of iron (for the shield);

- cable, electrical tape.

Tool List:

- ;

- ;

- lathe;

- ;

- ;

- roulette;

- marker;

- spanners;

- tap for threading.

The process of making a lawn mower:

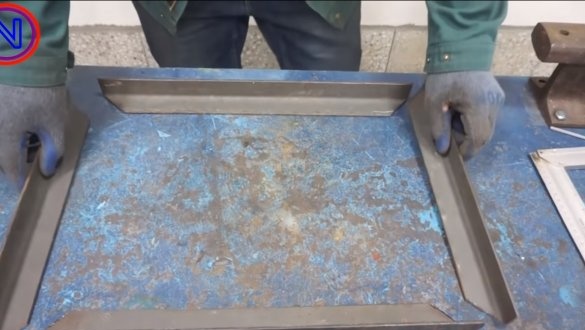

Step one. Frame

First of all, we will make the main part of the frame, it will be square or rectangular with us. To make the frame, you will need an iron corner, cut it, and then weld the structure. We clean the welds with a grinder so that everything looks neat.

Now the frame is ready, set the wheels on it so that the mower can ride. It is better to choose wheels with a large diameter, so the mower will better pass obstacles. We drill holes for fixing the wheels and fasten them with bolts and nuts. Each such wheel is able to rotate an angle of 360 degrees. However, only the front wheel can be rotated.

Step Two Knife

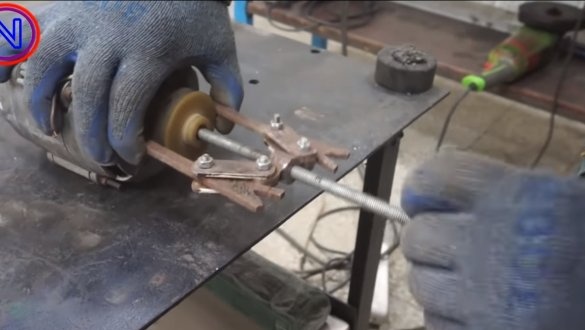

Next, we make a knife, and we will start with an adapter that allows you to remove the knife for replacement or sharpening. Remove the pulley from the motor shaft and grind the adapter from the round timber. In the round timber you need to drill a hole and cut the thread under the bolt, which will be used to screw the knife.

Well, then we make the knife itself, here the author used an iron plate, but it is better to use steel so that the knife retains sharpening longer.In the center of the workpiece we drill a hole and then you can sharpen the knife. We work with a grinder using a thick grinding disc or a petal nozzle.

Step Three Engine mount

At the next step, we have to install the engine on the frame, for this we make fasteners from an iron plate. As a result, the fasteners should be in the form of the letter "P". We drill holes in the fasteners, it will be attached to the frame with bolts and nuts. Thanks to several rows of holes, it will be possible to adjust the height of the knife. In the center of the bracket, we drill a hole for the motor shaft, and we also figure out how to fix it securely, it all depends on the shape of the motor housing and the mounting options.

Step Four Handle and assembly

Let's make a handle for a lawn mower, here we need a piece of round and a piece of profile pipe. Just weld the steering wheel in the right place, depending on your height, so that it is convenient.

Also at this step you can install the engine in its place and fix the knife on the engine. It is important that the knife is fixed securely and does not fly anywhere if it suddenly comes off.

Step Five Finishing touches

At the end, we make a guard for the lawn mower, it is necessary so that pieces of grass, sticks or even stones do not fly into you. A piece of sheet iron is suitable for the shield, we install it on a lawn mower.

Next, we carry the cable along the frame of the lawn mower to the steering wheel. We choose a good cable with good insulation so that you will not be shocked. It is also useful to install a switch on the steering wheel so that the mower can be quickly turned off if something happens. The author sets the outlet as a switch.

That's all, the car is ready for testing. The author mows rather dense vegetation with the help of home-made, and the car copes with the task. The most important thing in this matter is the engine power and the number of revolutions, so the motor should be more powerful. If the turns are too small, you can try to make the knife larger in order to increase the angular velocity. If you paint a homemade product, everything will look fine and the iron will not rust. On this project can be considered successfully completed, I hope you liked the homemade. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!