Power (network) transformers in the power supply units of devices are used less and less and there are reasons for this - pulse converters are much more compact, have many higher characteristics. However, in some cases, a textbook low-frequency transformer is preferable.

The main parameters of the transformer are determined during its calculation, a number of characteristics are also affected by the selection of materials. Impregnation of the transformer with varnish allows the use of inexpensive (including used) materials to improve the situation. The varnish inside the coils contributes to their better cooling (especially true in toroidal transformers), heals most of the microdefects of the varnish insulation of the winding wire (especially true when using old or second-hand wires), fastens the coils of the wire in the coils, not allowing the magnetostrictive effect to mess up with loose winding and non-locking interlayer insulation. Increases the strength and survivability of insulation. In general, impregnation increases the reliability of the transformer, very much reduces the buzz, especially when not sufficiently careful winding and the choice of heavy conditions. Improves "climatic modification".

It should be borne in mind - impregnation of a transformer significantly increases its distributed inter-turn capacity, this worsens (changes) the frequency response (amplitude-frequency characteristic) of signal transformers. For example, impregnation of output transformers (tube) of stationary sound amplifiers is not used. It leads to a blockage of the frequency response at high frequencies.

What was needed for work.

Tools, materials.

Homemade Vacuum Chamber, a varnish for impregnation, a container, a drying cabinet (you can get by with an electric stove), a set of medium-sized bench tools for assembling a transformer, a set of tools for electrical installation (checking the operability of a finished transformer).

Let's get started.

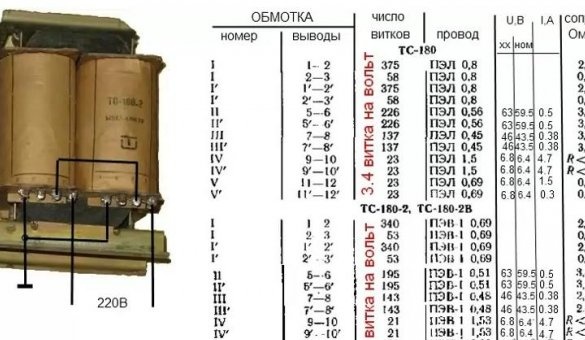

Subject - a transformer for a laboratory power supply unit based on TS-180-2. This is a good (despite a slightly increased induction in the core and current density in the wires), a reliable and convenient transformer used in tube TVs. The primary windings and the electrostatic screen are left in their original form, the secondary windings are counted and rewound.The main data of the transformer TS-180-2 are summarized in the table.

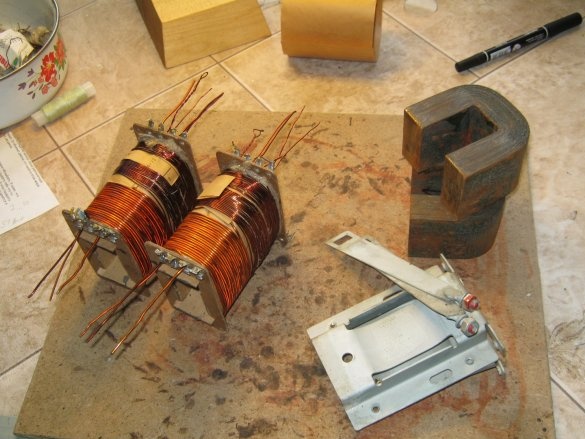

It was required to wind several low-voltage windings, the standard high-voltage windings (many turns, many layers) were removed. Used free regular gaskets between layers of thick paper. The number of turns for new windings was small, a wire of significant diameter - winding was done manually, without the use of special mechanisms.

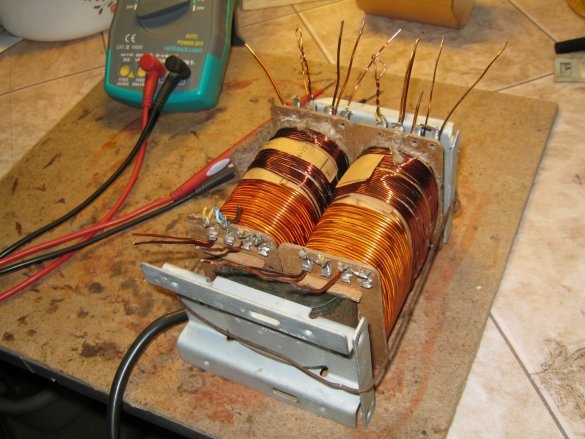

To check the correctness of the winding, the transformer was assembled “on a live thread”. The halves of the core are pulled together with wire, the ends of the winding leads are stripped of varnish insulation. A multimeter found the conclusions of each of the windings, a test inclusion measured the voltage without load. Order. There are tensions, they are within normal limits.

The transformer was dismantled, on coils it made the top “decorative” layer of paper insulation.

I tried the coil on a vacuum chamber from a standard cut-off 0.75 liter can. As the poet said with sawdust in his head, he enters and exits.

The process will require heating and drying at elevated temperatures. Used for these purposes an old domestic oven. No temperature controllers are provided for in its design, it was necessary to manually turn on and off. With frequent use, such a device is better equipped with a simple thermostat. It is not necessary to have an oven at your disposal, the relatively small size of the coil allows you to get by with some kind of surrogate. For example, when he was at school, the author used a large tin can placed on an electric stove (the ability to put it in the open air). So that the coils do not burn, sand was poured on the bottom of the can, fragments of ceramic tiles were laid. A piece of tin of the bank was covered from above.

Here, a layer of dry sand was also poured under the coil (to absorb the leaked varnish) and several flat stones were laid (so as not to spill the coil in the sand).

Of course, there are special impregnating varnishes that provide higher characteristics, however, with the usual non-military-space-tropical requirements for the transformer, varnishes on an alkyd, urethane or glyphthalic basis from the nearest building store successfully work. The described technology is for them. The alcoholic varnish with shellac is also very convenient for impregnation and, due to its low viscosity, impregnates paper well and fastens coils of coils. It is especially good for coils with thin wire. Unfortunately, currently this varnish is very rare and expensive.

In the described experiment, alkyd-urethane "yacht" varnish was used. At my disposal was a varnish with a pigment (tinted). This is not at all necessary (used the existing one), and if you purchase a special varnish for impregnation, it is better to choose a regular transparent one.

Varnish is a rather viscous thing, it will be reluctant to crawl into bottlenecks. Reduce viscosity by diluting with an appropriate solvent or (better) by heating. It is best to warm the varnish in a water bath on an electric (without open flame!) Stove. It is even better and more convenient to separately heat hot water (take it from the water supply) and place a jar of varnish in it.

The coil with the wire is much colder than the varnish. It is of considerable mass and has a developed (inside) surface - the heated varnish will be quickly cooled. It is also highly advisable to preheat the coil to 70-80 degrees. It is convenient to warm in the same oven-dryer, such a temperature to the touch - "the hand no longer tolerates." The coil should be warmed up as completely as possible. It takes time.

After completing all the preparatory operations (heating the coil and varnish) we proceed directly to the impregnation. Everything is obvious here - we put the coil in a container, fill it with varnish with our head, wait five minutes (the varnish will soak up and crawl where it can), add varnish and close the chamber lid. We pump out as much as possible air. In this case, the varnish surface may foam (these are air bubbles coming out of the coil), so pumping is best done in portions, allowing the foam to settle. With insufficient heating (low varnish mobility), the process can take a while, so the pumped vessel should also be heated.The easiest way to do this is by placing it in hot water.

Finally, when the maximum permissible vacuum chamber design has been achieved and new air bubbles do not come out of the coil, the impregnation can be considered complete. Air is let into the chamber, the coil is removed from the varnish. Let it flow a little and place it in a heated drying chamber. Part of the varnish from the coil inevitably follows, therefore it is useful to fill it with dry sand under the coil. A good indicator of the process is the color of the outer paper wrapper of the coil and the evaporating volatile part of the varnish. The color should not be too dark, burnt, although this happened. Usually, a light brown, brown hue was considered a satisfactory result. During the drying process, it is better to turn the coil several times around the axis. Tools for this must be prepared in advance.

The evaporation of volatiles from varnish, as practice shows, is the main indicator. As long as the varnish is in its original form in the coil, solvent and volatile fractions evaporate from it. It looks like white smoke with a characteristic odor. It stands out quite intensively, so the process is not permissible, carry out indoors. Unless, in a good fume hood. When the smoke has ceased to be emitted, drying can be stopped. It should be borne in mind that the varnish inside the coil is not hardened. It is a softened (temperature) dense mass. Therefore, it is not worth shaking and pulling a hot coil. It must be carefully, without moving the wires, removed from the oven and put next to it (at room temperature) to cool.

After cooling, the coils should absolutely not have the smell of varnish, and external burnout is also undesirable.

The hardened varnish smudges are removed with a knife, the contact petals are cleaned, the tunnel for the core is carefully leveled. The transformer leads are aligned, their affiliation is determined. Their integrity is checked. Conclusions are shortened to working length, stripped, torn.

The transformer is assembled, special attention is paid to the core assembly. All plates should be pressed tightly, the twisted split core should not have delamination. The halves of its core should be tightly compressed. It is not permissible to get (raking from the walls of the tunnel when the landing is too tight) debris between the compressible surfaces. When assembling a transformer with a stacked core, to minimize the gap between the plates, the core from the ends is squeezed in a vice through a rubber gasket.

It is very good if the dimensions of the vacuum chamber allow you to place the entire transformer assembly. This will allow to achieve good results with relatively simple means, although such a transformer is completely deprived of maintainability.

Babay Mazay, May, 2019