I welcome fans to craft, today we will look at how to make a miniature souvenir hatchet. Despite such small dimensions, you may need a hatchet in some life situations, it is made of high-quality steel and has been hardened. The hatchet can be hung on the keys, however, in this case it is better not to sharpen it to the state of the blade. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- a piece of damask steel;

- Dostochka for an ax

- oil for wood;

- epoxy adhesive;

- Reagents for steel pickling.

Tool List:

- grinder;

- blacksmith tools and oven;

- oil, oven, oven (for hardening);

- jigsaw;

- drill;

- belt sander;

- clamps;

- file.

Hatchet manufacturing process:

Step one. Forging

The process of manufacturing an ax begins with forging, everything is done exactly as in the manufacture of a large ax. Of course, there will be much less work here, so you can practice before making a large ax. The author uses steel Damascus, he had a piece. A little effort and now we already get a recognizable hatchet profile.

Step Two We are developing a profile

After forging, the profile needs to be finalized, we arm ourselves with a grinder and cut off the excess. As for hard-to-reach spots, they can be cut into pieces. Next, we install a thick grinding disc on the grinder and remove all minor defects. The author also carries out some grinding work on a belt grinder and with a drill.

At the end, we cut off the excess, grind the ax to a smooth state, and also form the rafts with a file. That's all, now the ax profile is ready.

Step Three Heat treatment

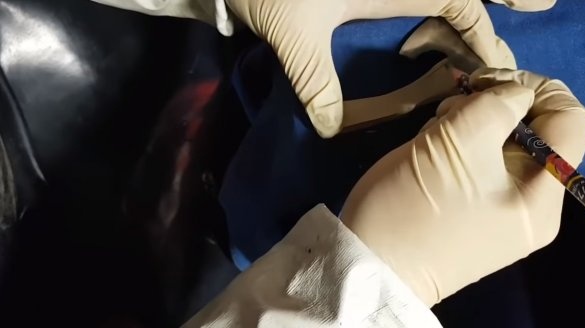

If desired, the ax can be hardened, its dimensions are small, so the author heats the steel with a gas burner. Well, then lower the ax into the oil. After hardening according to the rules, you need to let go of steel so that it is not fragile, such processes are carried out in a domestic oven.After hardening, we perform grinding to remove carbon deposits and other deposits.

Step Four Ax making

We make a hatchet for a hatchet, a piece of board is suitable as the material, draw the desired shape of the handle and cut it with an electric jigsaw. Next, the handle must be well sanded in order to form the desired shape. As a tool, a file, a drill and other similar tools are suitable. In conclusion, bring the pen to a perfectly smooth state with fine sandpaper.

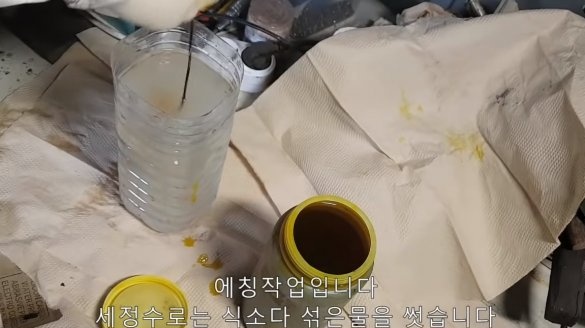

Step Five Etching

To highlight the damask pattern, we need a reagent for etching. We lower the ax into it for a while, and when the desired result is achieved, lower the ax into the soda to neutralize the acid. After easy grinding, a beautiful drawing will be visible on the ax.

Step Six Hatchet assembly

Everything is ready for assembling the hatchet, we install the handle on epoxy glue. And when the glue dries, soak the handle with wood oil. If desired, the pen can be decorated with twine. That's all, the hatchet looks great, it will be a great gift. This is the end of the project, good luck and creative inspiration, if you decide to repeat it like that!