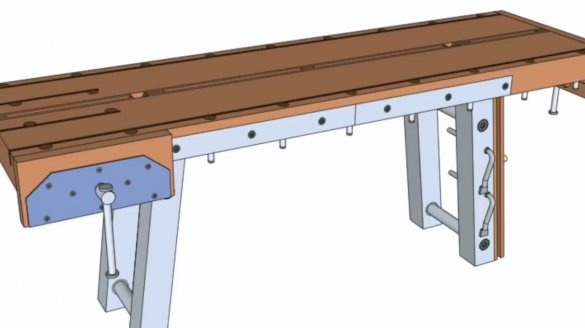

In this article, the author of the YouTube channel Andrew Klein will tell you about the process of creating a unique support stand for a workbench. The whole structure is made of maple. It is easily inserted under a workbench, and is fixed by clips.

Materials

- Maple board

- sheet plywood

- Two-component second glue

- steel bar

- Neodymium magnets.

Instruments, used by the author.

-

-

-

-

-

-

-

- mallet, hammer, square, tape measure, pencil

- .

Manufacturing process.

First, the author prepared a maple board, cut it in height from the floor to the workbench frame, but made the workpiece shorter by 15 mm. Then I cut two grooves on each side for the side stops.

The same grooved dado disk made two longitudinal grooves.

Along the entire length of the rack body, I drilled holes for the supporting fungus with a Forstner drill.

Now the author needs something that would temporarily hold the rack in the desired position before the pressure mechanism is activated. The master solves this problem with the help of neodymium magnets. Drills holes for them at the top of the rack. The vise, and the guide for the screwdriver is very welcome here.

Coats holes with second glue, and presses magnets into them.

That’s how easy the rack is to the steel frame of the workbench.

Then he proceeds to the manufacture of movable clamp elements. These structural elements should be made of another material - from birch, for example, or from birch plywood. Maple is softer and may crack. Having cut several long shtaketin and a pair of plates, He drills holes for articulated joints in them.

Again returns to the grooved disc, and makes slots for joints.

Presser shoulders cuts on a band saw.

Then it processes the edges and rounds the corners of the workpieces on an orbital sander.

Still need a couple of small transition levers.

Since the author wants the design to be collapsible in principle, he decides to make bolt clamps to the main part.Drills two holes in the upper part of the body, and cuts threads in them.

Hinge assemblies are attached to each other using small steel studs. The author intentionally cuts them shorter than their own thickness of plywood so that on each side he can plant a drop of glue for better fixation. From the ends of the studs it removes the chamfer.

The next stage of the work was much more tedious and lengthy than the author had expected: he had to assemble and disassemble his own several times devicebefore everything was finally fitted and adjusted.

It connects all the elements of the clamps, and glues the outer sides of the studs.

In the lower and central part of the housing, the stoppers are screwed with self-tapping screws, having previously countered the holes.

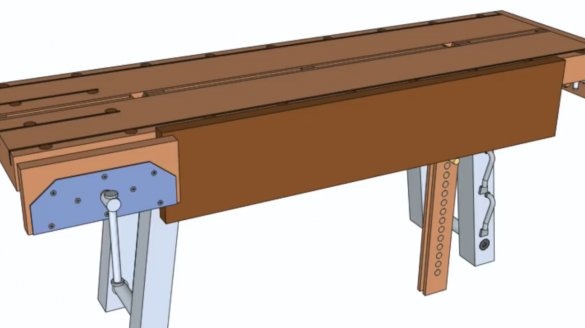

So, the clamps, and the body are ready, you can assemble.

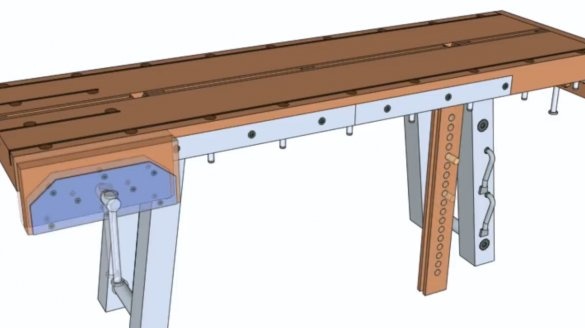

Now it is clear that when the author lowers the “shoulders” of the rack down, wooden legs extend from the bottom of the rack, so that the rack rests on the floor and is jammed along the height of the workbench. To the bottom of the legs, the master glued felt squares.

Here is the fixture and done. It can be seen that it rises above the surface by 3 centimeters.

Now you can try it already with a workbench. The device conveniently hides behind the side leg. You can magnetize the rack anywhere in the profile. And lowering your shoulders - firmly fix it. To select the desired height, it is enough to install the supporting fungus in the desired hole.

This fixture works perfectly in conjunction with a wide vise. It is in this way that it is convenient to fix large workpieces on a workbench.

Thanks to the author for a simple but useful tool for the workshop!

All good mood, good luck, and interesting ideas!