Hello everyone! There was a free day, I decided to make a knife, dig deeper into the metal and found the rest of the spring, a piece of 5 by 8 cm, I think that's enough for a knife, 5 mm thick.

And so we need:

Welding

Grinder with cutting and grinding disc

Getting down to making a knife

1. To give strength to the steel of the knife, I scald it by electric arc welding with electrodes with fluoride-calcium spraying, grade UONI 13/45. I put the metal unevenly, as if I mix metals

2. I forge metal into a bar, then I betray the shape of a knife. I apologize to the process of forging I don’t have, it was raining outside. Before forging, I release the metal in the oven at 240 degrees, for two hours and cool in salt. Next, heat the workpiece, sprinkle it with brown, heat it again, forge it and sprinkle it again with brown, here is a semi-finished knife.

3. Grind the surface with a grinder periodically wetting in water, grind the knife to check for defects of lack of penetration

There are slight lack of fusion, but superficial. I thought about how to make a hilt for a long time, I didn’t think of anything, I decided to saw it off and make a handle from wood.

4. I grind the blade wet by hand, on a medium-grain stone.

And I grind it. There are small cracks on the surface of the blade - this is after welding, maybe somewhere the slag has not been removed.

Well, now I'm getting down to the slopes.

5. Descent. I decided to make a little curved slopes. I bring down the slopes on the sharpener, but not until the end

Of course I bring down the slopes with a narrow file, otherwise I’ll remove the excess on the grinder or something extra.

5.5. Quenching quenches the heating to a temperature, checks for magnetism, does not magnetize, dip in heated oil, so until you achieve the necessary quenching. The last heating and dip in water - that’s all with hardening.

6.Hard. For guards, I have a 50mm bronze blank

I cut 8mm thick, drill a hole in the center.

Trying on a knife. I eliminate the shortcomings

I betray the desired shape with a file

I grind manually with fine sandpaper, polish

7. The handle. I decided not to bother and make a pen from a piece of birch, dry.

I take off the bark, I give the necessary, convenient form to the file on the tree. I try on

Once again I check everything, process it with sandpaper. Into the rider’s hole, mixing small sawdust with epoxy glue, ramming the hole, inserting the knife shank into the handle, letting it dry for a couple of hours.

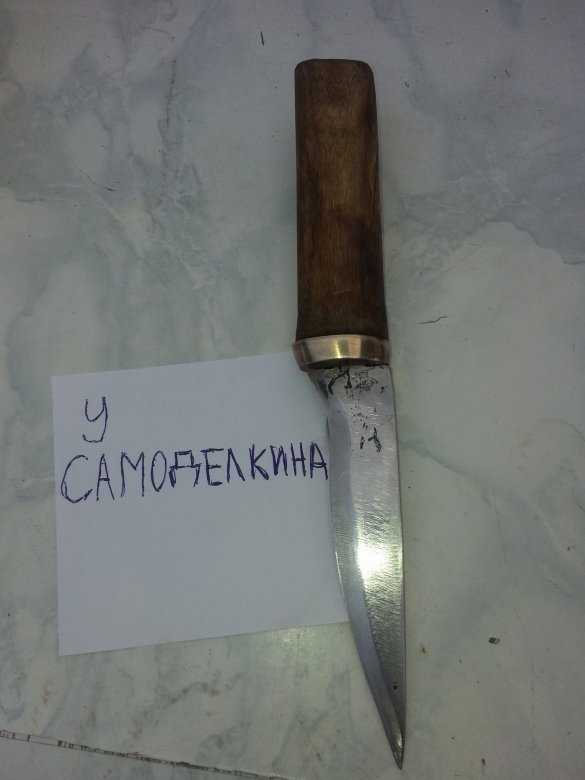

8.Final processing. I go through everything with fine sandpaper, I burn the handle a little, I go through sandpaper. Next, I put the knife in a vacuum impregnation chamber in linseed oil for a day. That's all, until I grind the blade in the mirror, there is nothing, so do not judge strictly that I can do it.

Thank you all for your attention and to new Homemade friends!!!