As you all know, how many tools and fixtures to the workshop either buy or do - there is always something that is missing.

In this article, the author of the YouTube channel "Mistry MakeTool" will tell you how to expand the functionality of the drilling machine. Namely, to make for him an orbital nozzle for grinding.

Materials

- Bolt, washers, nut M14, M8

- Bearing

- sheet plywood

- M8 wing nuts

- Spray paint

- Sandpaper

- PVA glue

- Two-component polyester resin.

Instruments, used by the author.

- Wrench

- Feather drills for wood

-

-

- Vise, clamps [/ leech]

-

- Joiner's knife.

Manufacturing process.

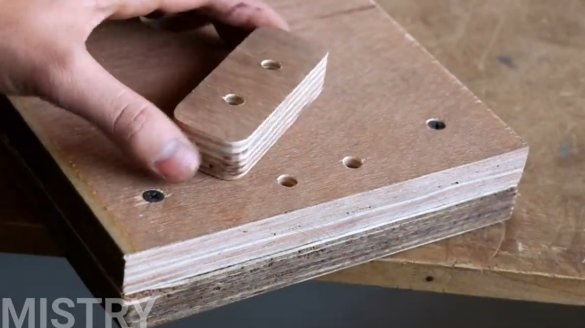

So, the master begins by cutting blanks for the table from thick plywood.

Cutting two identical rectangular blanks, and processing their ends, glues them together. Presses with clamps, and additionally fixes with screws on the corners.

Drills a hole with pen drills on the top side of the table. The first drill 32nd, it will be a bearing seat, it should be equal to the thickness of the bearing. The second - the 24th drill, for the bolt head.

He tries on a support for an emphasis, drills in it and in a little table on two 8 mm openings for clamping bolts.

On the bottom side, it drills holes for the bolt heads, and glues them there using polyester resin.

Then glues the stand to stop.

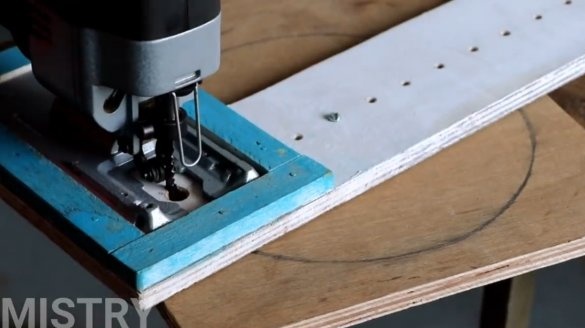

Now, using a circular nozzle for a jigsaw, cuts out the disk. A hole with a diameter of 14 mm is drilled in the center of the disk.

Attaches the disc to the back of the sandpaper, cuts the workpiece, and glues it to the disc.

All parts are ready for assembly.

Puts the bearing on the bolt, laying the washers, inserts it into the grinding disc. Then tightens with a nut through a large washer from the upper side.

Now the author makes a test assembly, installs the disk in its place.

Establishes a triangular emphasis, presses it with wing nuts.Then it clamps the edge of the bolt in the drill chuck, and checks in operation.

Parses the nozzle, and stains with spray paint.

Now the nozzle is ready to work! Even at low speeds, she copes with her tasks. It remains only to make a few discs with emery of various grit. Or stick Velcro textile Velcro onto the disc, and use sandpaper for orbital sanders. Then replacing the paper will be much easier! A similar technology is described in [url = https: //homediy.washerhouse.com/en/12177-mnogozadachnye-napilniki-dlja-nazhdachnoj-bumagi-svoimi-rukami.html] this article.

Thanks to the author for the simple but useful device for the workshop!

All good mood, good luck, and interesting ideas!