Very rarely come across very unusual tools, which can have a very wide range of applications. In this article, the author of the YouTube channel "Gökmen ALTUNTAŞ" will tell you how he made a portable band saw driven by a screwdriver.

At first glance, this device It has a very complex design, but it can be made in just a few hours. In addition, especially expensive materials are not required. The most expensive will be the cutting blade. A set of bearings can be found in the car shop.

Materials

- Bearings, Aliexpress links:,,

- Band saw blade 835 mm

- Sheet plywood 18 mm

- Wooden beam 25X40 mm

- Steel bar 10 mm

- Rubber from a car camera

- Steel strip 3 mm

- Washers, screws

- Neodymium magnets, furniture hinges

- Mortise furniture nut 6 mm

- PVA glue

- Second glue.

Instruments, used by the author.

-

-

-

-

-

-

-

-

- Tap M4

- Vise, pliers, wire cutters, ruler, mallet, hammer, chisel, scissors, knife, screwdriver

- Drills 1, 3,5, 9, 9.5, 10 mm.

Manufacturing process.

So, the author kindly shared detailed drawings of all elements of the future design. All of them are presented at the end of the article.

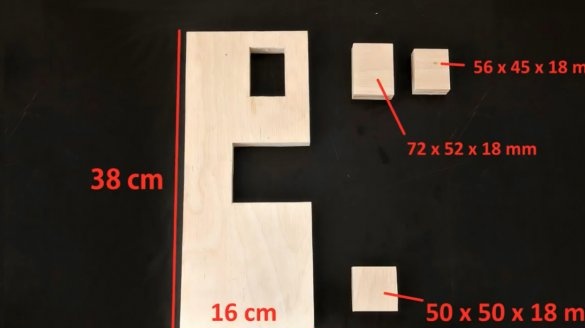

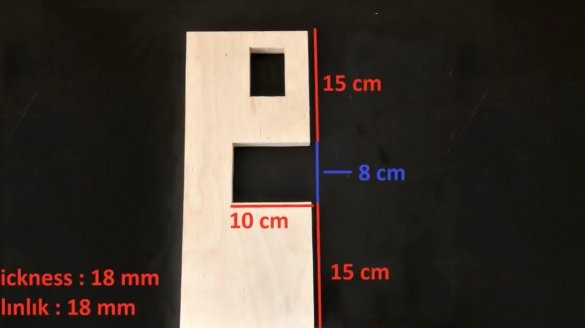

First, he set about making the base of the nozzle. From a plywood sheet with a thickness of 18 mm, he cut a plate measuring 380X160 mm. Then he made a slot 100X80 mm in the plate.

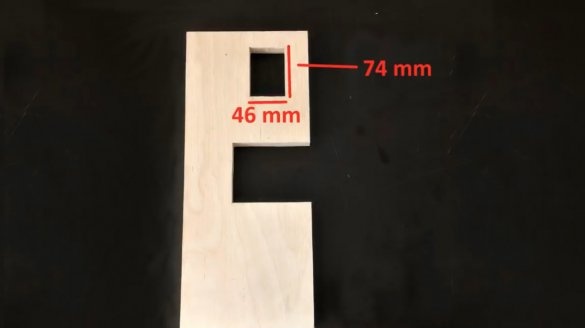

I drilled four holes for the entrance of the jigsaw blade, and cut out a window 74X46 mm. I processed the corners with a file.

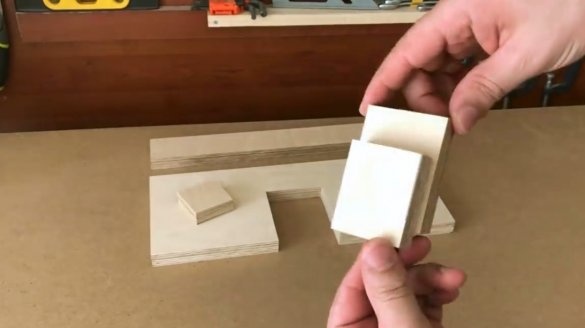

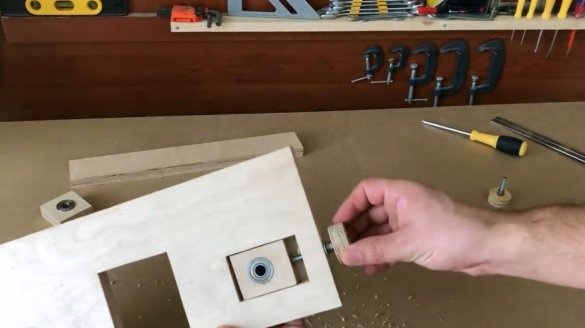

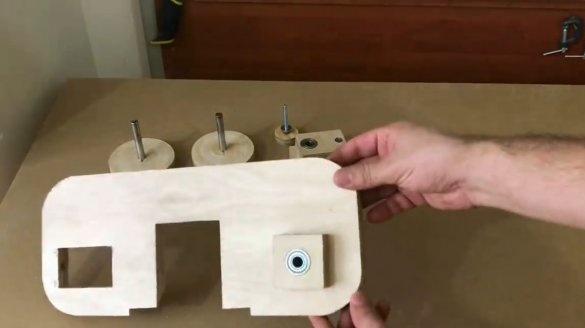

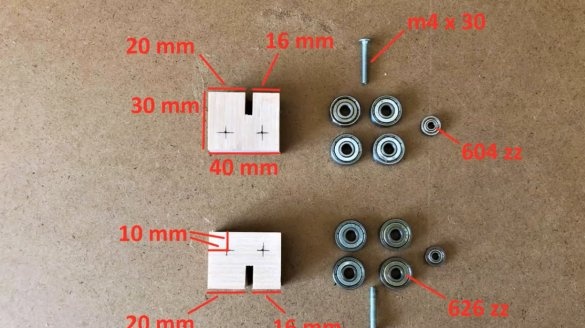

Then he began to manufacture a tension carriage. I cut two rectangles 55X45 and 72X52 mm, and glued them, stepping back from the edge of 10 mm.

The result is such a carriage, it should move freely along the length of the window.

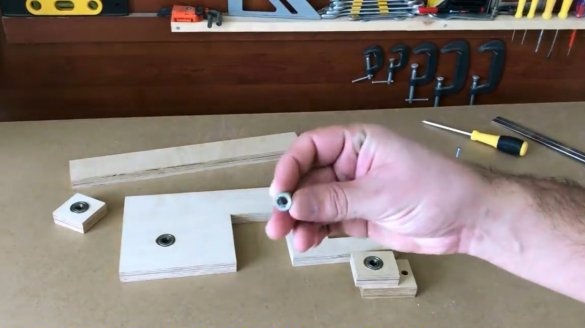

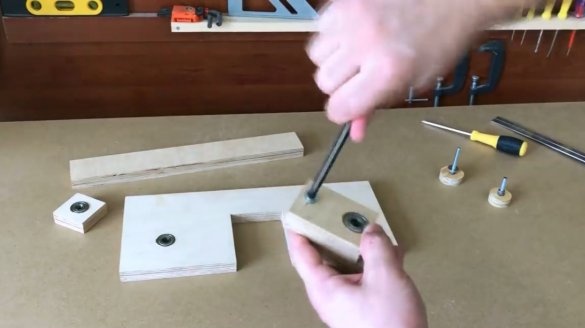

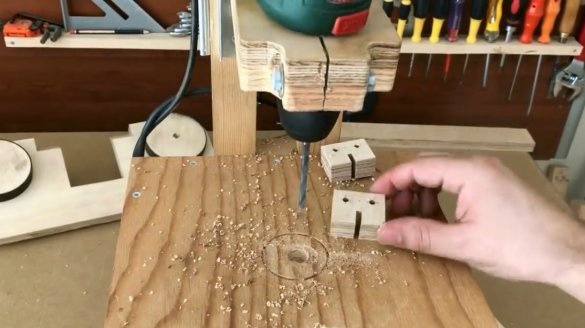

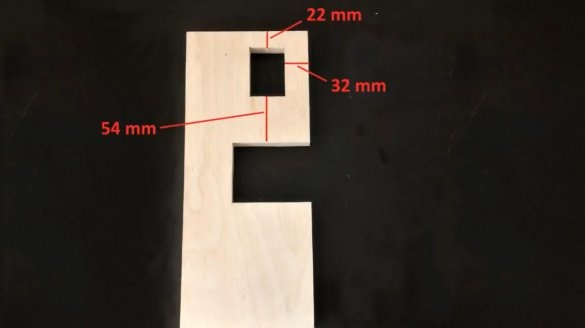

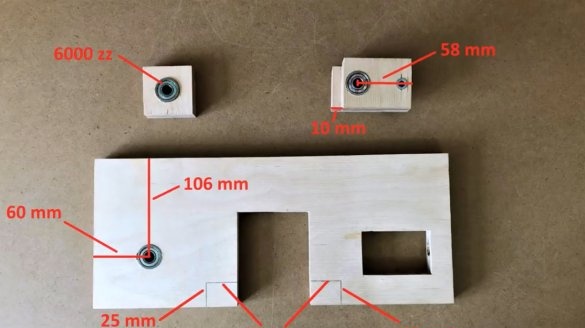

Marking holes are made with a thin drill, and then it drills blind grooves for bearings 6000ZZ with a 26 mm diameter crown. Holes are made on both sides of the parts.

Then the remnants of plywood are removed from the grooves.

Then the central holes are drilled with a 10 mm drill.

Now the master presses the bearings into place in the carriage, base, and retaining block. He does this with a hammer and a plank.

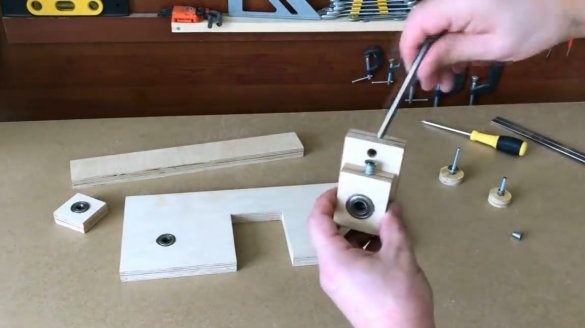

In the carriage, the master drills two holes with a diameter of 9 mm. Mortise furniture nuts will be screwed into them.

Using a hex wrench, screw the nuts into the holes.Adjusting wings will be installed in these places.

A hole for the stud is drilled from the end of the base.

Inserts a stud with a lamb, and screw it into the end nut of the carriage. This will be the belt tension adjuster.

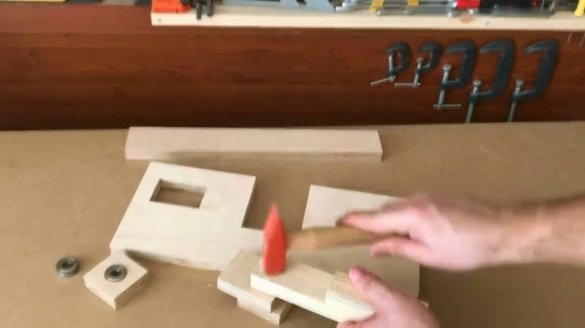

Using an electric jigsaw, cuts two inclined planes at an angle of 45 degrees.

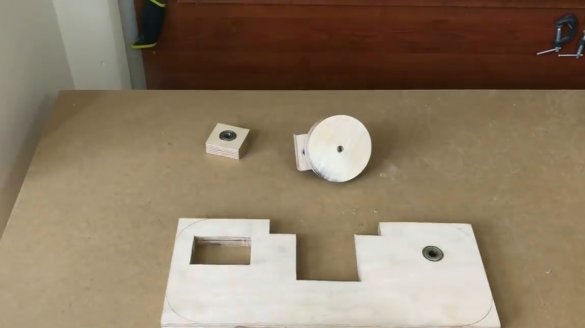

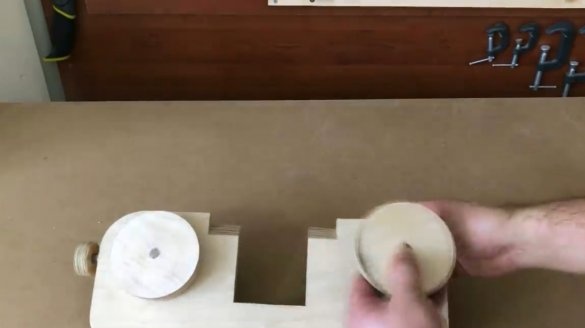

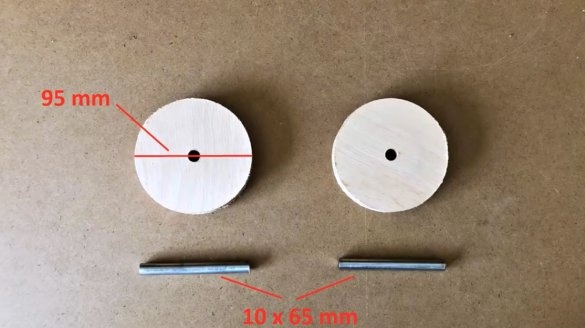

Using a hand mill with a circular nozzle, cuts two discs with a diameter of 95 mm. They will be required for the manufacture of pulleys.

Drills 9.5 mm holes in the center of the discs.

On steel bars with a diameter of 10 mm makes two shallow cuts near one edge. They will clog a key made of steel wire.

With the help of a mallet, she puts pulleys on the shaft, and clogs the keys.

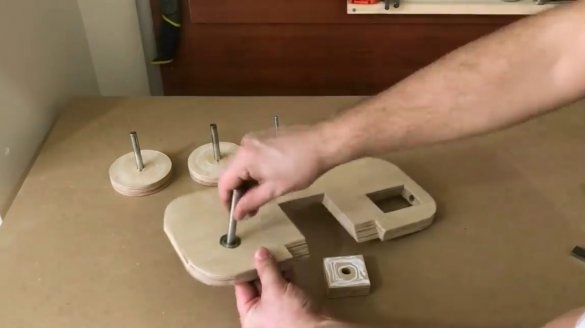

He puts a washer on the shaft, installs it in the carriage, and clamps it in a vice. Then, with the help of a screwdriver, he receives an improvised lathe. Grinds discs from all sides for balancing.

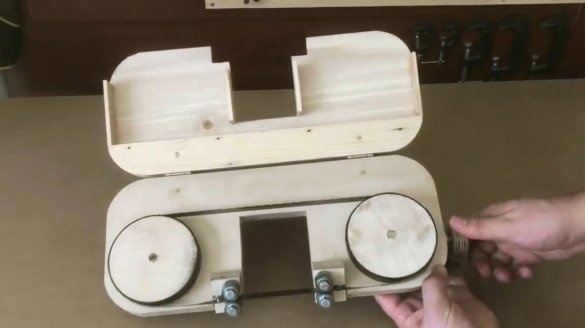

Then marks the arcs at the corners of the base, and cuts them.

Inserts a steel bar into the bearing, and glues the support block.

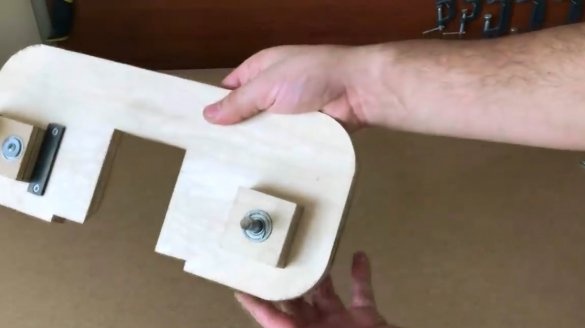

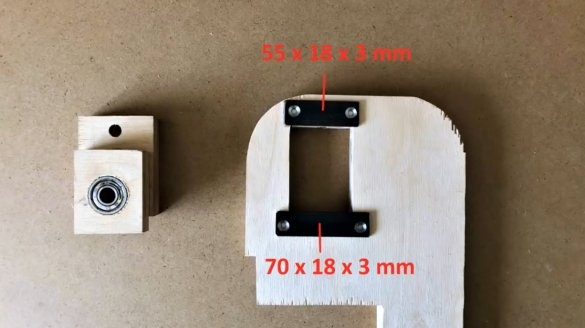

The master made two lining steel plates. For one of them, he is milling a seat.

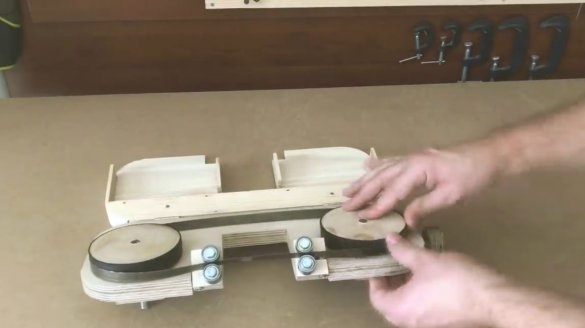

And screws the plates to the base, trying on the carriage. Installs both lamb in the carriage. One is the tension adjustment, the second is the tilt of the carriage.

Inserts pulleys into place, and marks the shafts.

In one shaft drills a transverse hole of 1.5 mm in diameter. Then, leaving a margin of 45 mm, cuts off the shaft.

A 3.5 mm hole is drilled at the end of the second shaft, and M4 thread is cut into it.

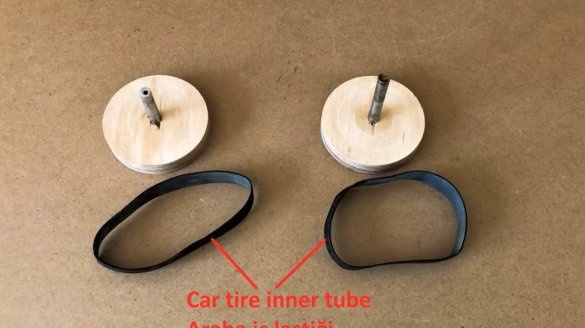

Using rubber from a car camera, makes two strips. Then glues them to the outside of the pulleys, and cuts off the excess.

Two washers are placed on both shafts.

A pulley with a short shaft is installed in the carriage, and is fixed with an M4 screw through the washer.

The drive shaft is fixed with a piece of wire, passing it through a longitudinal hole.

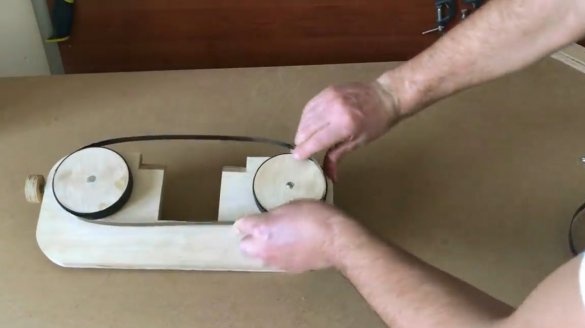

Now the master checks how the canvas will be stretched.

In two U-shaped blanks, drills two holes for mounting bearings.

Then a small hole for fixing screws.

On the side of the workpiece, it drills a hole, inserts a 604 ZZ bearing into the groove, and fixes it with a screw.

The author applies glue on the bevels of the base, and fixes the guide blocks with a self-tapping screw.

Assembles the side guide bearings on the screw, laying washers on both sides. And screw them to the blocks.

A lid is made of a piece of thin plywood.

Then glues it to a wooden block, and screws the lid to the base with furniture hinges. In order for the lid to be fixed, the master installed two neodymium magnets in the bar and base.

So, the device is ready, you can pull the cutting blade.

The cover is reliably held by magnets.

The author tested the device a bit, and decided to add a handle. And, of course, you need to soak the wooden elements with linseed oil or wax.

It fixes the drive shaft in the chuck of a screwdriver, and you can begin to test.

Such a saw copes with a profile pipe of various sizes in a matter of seconds.

Here, the saw cuts into such thin rectangles by a steel profile.

Detailed drawings of project details.

Thanks to the author for the idea of a useful, and unusual nozzle for a screwdriver!

All good mood, good luck, and interesting ideas!

Author video can be found here.