Greetings the inhabitants of our site!

The author of the YouTube channel "Fiery TV" for further projects, well, and just for various kinds of experiments sometimes quite high temperatures are necessary. Therefore, it was decided to make a homemade bugle. And today we will be manufacturing gas forge. And for this, a powerful burner is simply necessary.

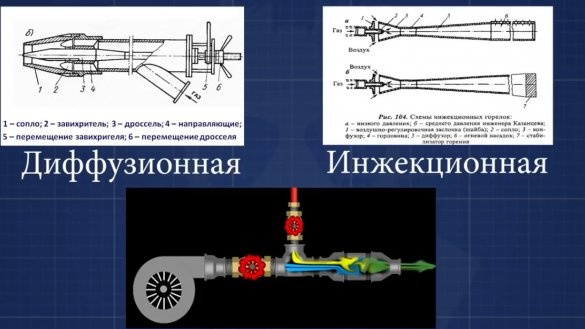

So, then we need a fairly powerful burner. You can find burners of various modifications, for example, injection, diffusion, supercharged. But their power, whatever one may say, depends entirely on how much fuel (in our case, gas) burns out during operation for a certain time period.

For example, an injection burner.

This design is quite good, but still it has a rather significant drawback. The fact is that the power of a burner of this type is directly proportional to its size. You must admit that it is simply unrealistic to provide a burner with a large amount of fuel if the design itself is sufficiently modest in size.

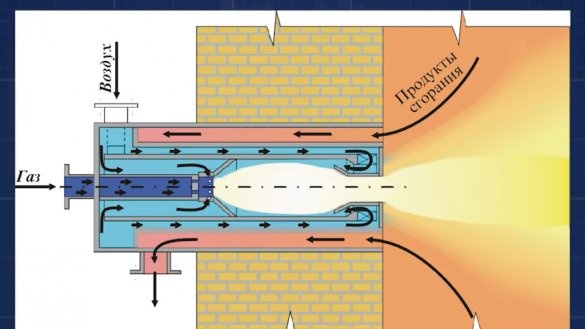

Most furnaces used in industry are most often equipped with supercharged burners, but in addition they have such a thing as air pre-heating.

If the temperature of the gas-air mixture is about 400 degrees Celsius, then the length of the fire beam is reduced by 2 times. This allows you to burn more fully the same amount of propane in less time. And at the same time, such a torch will have a higher flame temperature.

So let's try to collect do it yourself such a burner. If you follow this instruction, the result is a device that allows you to save 20 percent, or even 30 percent of fuel. The task of fuel economy is crucial. This applies not only to stoves, but also to gas boilers used for heating various buildings.

The author decided to make a burner from a pipe with a diameter of 1 inch.

Now, using heat-resistant sealant, we collect all the components that will heat up during the operation of the device.

There are not many such parts, since only a small part of the pipe will be heated, and the remaining pipes will be continuously cooled (blown) by the air stream. All connections need additional sealing with a special tape that can withstand quite high temperatures, in this case about 500 degrees.

The design of the supercharged burner does not require the installation of a jet, since in this case there is no need to think about the gas supply speed. The larger the flow, the easier it will be for the gas to mix with the injected air.

On one side you must install an inch crane. It is necessary in order to divert part of the injected air. The greater the amount of air leaving the system through a given tap, the correspondingly less air mass forms a mixture with propane. Here is such a primitive adjustment design.

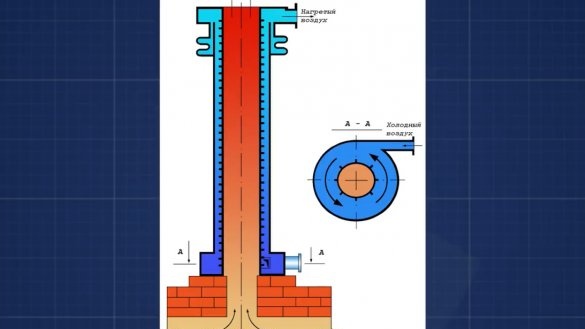

Above, an air injection device will be connected to the system.

This supercharger has 6 speeds and has sufficient power.

Next, from the segment of the 40th pipe we make the following detail.

The result is such a cone. Now it is necessary to weld a piece of thread to it, and then weld the joints.

We clean the resulting part and here is what we have as a result:

As we know, metal from heating can easily burn out, therefore, using this threaded connection at the end of the pipe, there will not be any problems replacing a large part.

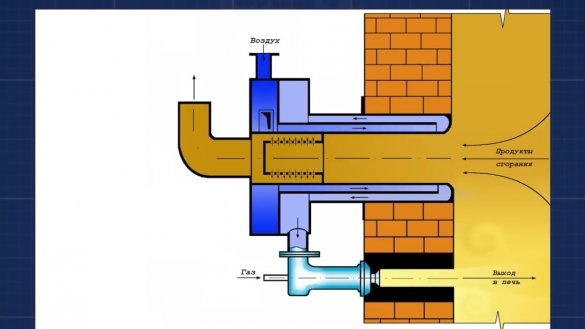

Next, the burner mixer must be passed through such a square profile, let's call it a tap.

According to the plan, the heated gases, the passage through such a peculiar chimney, will contribute to the heating of the gas-air mixture entering the hearth.

On the coupling, it is necessary to cut such teeth.

Firstly, they will serve as a radiator, and secondly, these teeth will contribute to the creation of additional turbulence of the exhaust gases, thereby improving heat transfer with the mixer tube.

Now we place the gas mixer with the radiator inside the gas outlet.

At this stage, you can already test our device. We connect a propane cylinder, a gearbox and a safety valve (check valve).

In this form, when the turbine is turned on, the burner goes out and nothing works. Let's try to fix this with a stainless steel dishwashing net; it should help to cause all sorts of turbulence and additional twists.

As you can see, it’s already better, but still not the same. Will have to redo the nozzle. We make a narrowed nozzle.

Well, the homemade ashtray is fully assembled. Further, the author continued to experiment using various nozzles. For more details see the original Author’s video:

That's all. Thank you for attention. See you soon!