Many of you are very interested in various homemade knives. To date, so many of their variants have been manufactured in the world that no one will even take it.

In this article, the author of the YouTube channel George Kosilov will tell you how he made a powerful knife for various handicrafts.

This knife is similar to the Russian jamb knife, it is a boot knife. Its cutting edge is located on an oblique face, and has a one-way descent.

Materials

- Old file

- Paracord

- Sandpaper.

Instruments, used by the author.

-

- Belt sander

-, flap disc

-

- Vise, ruler, hammer, core, marker.

Manufacturing process.

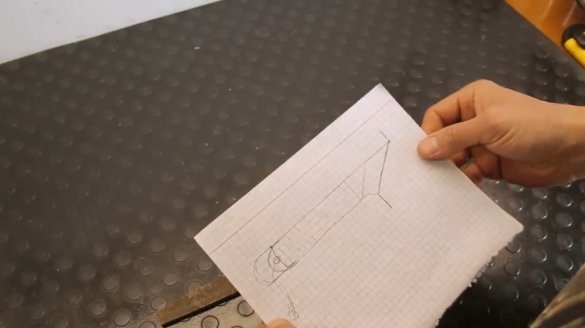

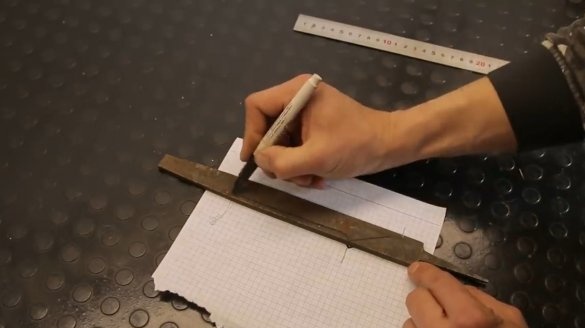

So, the author drew the desired shape of the future knife, and transferred it to the workpiece from the file.

Having fixed a file in a vice cuts off unnecessary parts. In this case, it is necessary to constantly cool the area where the cutting edge will be. Otherwise, it will lose strength.

Then cuts off excess metal in the handle area.

Levels the edges of the workpiece.

Installs a stripping flap disc, and polishes all surfaces.

Now marks the future edge of the descent.

The rest is up to the grinder. Forms a descent, and rounds the shank.

Then heats the shank to facilitate its further processing. After cooling, the steel will become softer.

Kernit, drills a hole in the shank, and countersinks it.

Polishes all facets with 240 grit sandpaper.

It remains to sharpen the cutting edge of the blade. This can be done sequentially from the 240th to the 600th sandpaper. With further grinding, and increasing the grindness, it is necessary to moisten sandpaper with water.

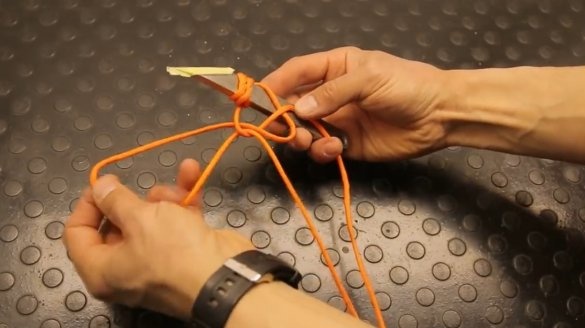

To design the handle, the master decided to use a paracord, it will take about a meter. Having folded the cord in half, it begins to tie knots.

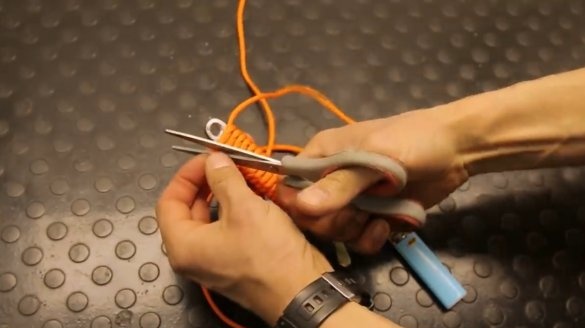

This is an ordinary knot, only you need to tie it on both sides of the handle. The excess cord is cut off and melted with a lighter. For greater durability, the cord on the handle can be impregnated with epoxy resin or varnish.

Even with a not very serious sharpening, it is quite possible to shave your hair.Yes, and sharpen pencils perfectly.

In more detail, the technology of heat treatment and sharpening of a similar knife is described in a recent article about japanese kiridashi knife.

Thanks to the author for the idea of a simple but powerful knife for skilled people!

All good mood, good luck, and interesting ideas!

Author video can be found here.