Walking once again at all the well-known popular American auction, the author of the YouTube channel “Good Master” came across one rather interesting device.

The fixture is really needed, but of course the author didn’t order it, since making the exact same tool do it yourself not so difficult.

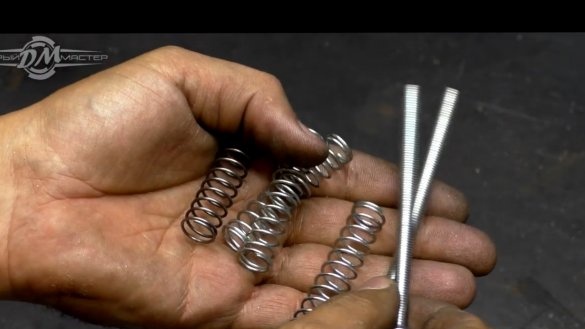

For the manufacture of the American device for milling, we need: a pair of M6 screws, springs (the author used from a secateurs), a piece of sheet metal and a lathe.

Perhaps, we will begin with turning works. First, we carve a few gadgets from yellow metal. For this device, the most ordinary nuts are also suitable, but the author decided to go a slightly different more difficult way. First you need to remove a small part of the metal on top. Dimensions in this case are not critical, so complete improvisation.

Then you need to drill a hole with a diameter of 5 mm for the m6 thread.

Next, we make knurling, we grind a little more and you can cut the thread.

About the knurling. The master also has other videos for this purpose, but he likes this picture more than others.

Agree, the product would have an unfinished appearance, if you did not remove the chamfers. Therefore, the next step is this procedure.

Now you can cut the resulting nut. We face it from the reverse side, countersink a bit and also remove the chamfer.

For smaller nuts, the author installs a smaller diameter bar in the machine, since he does not have much non-ferrous metal, so you have to save.

In this case, the operations will be exactly the same as in the previous version. There is only one exception, the very first operation will be grinding the bar with a soft bar.

In the center, we also drill a hole with a drill with a diameter of 5 mm for the m6 thread, since all these nuts will be screwed onto the same screw.

As a result, here we have such a beauty.

In total, such small gadgets we need 4 pieces.And if there are brass products, then why not polish them. Agree, because they will look so much more beautiful. Further, the author moves from the workshop to the old barn, in which he has an emery set with a polished circle and proceeds directly to polishing.

The result is just such a set of gadgets.

Assembled, it will all look something like this:

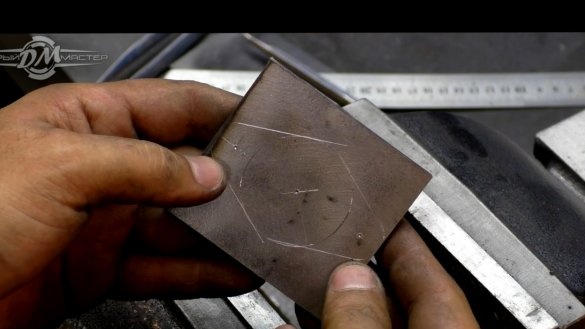

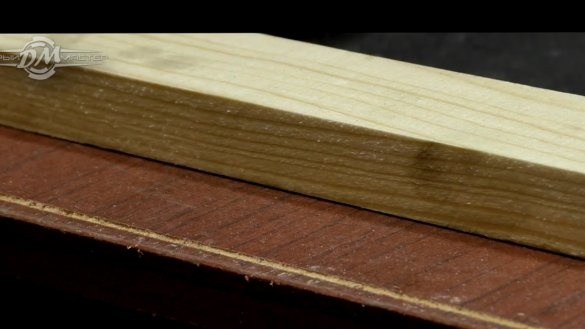

The device is not tricky, it remains to do a couple more parts and you can proceed to assemble the structure into one unit. Sheet metal in this case, you must first align and cut the jam from cutting the guillotine. To do this, the author uses the most ordinary angle grinder (angle grinder), as well as a self-assembled grinder in one of the past projects.

After which the metal surface turns out like this:

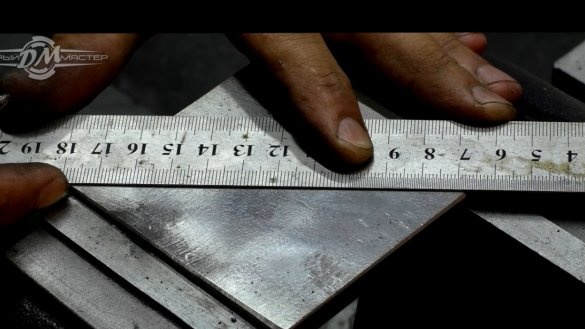

Then it is necessary to divide the workpiece into 2 parts and make the corresponding markup.

This will be the top part into which the tool itself will be installed. The first step is to use the grinder and cut off some of the metal with it, and grind the rest already on the grinder. You can of course do this on an ordinary emery, but this quality of processing is unlikely to be achieved.

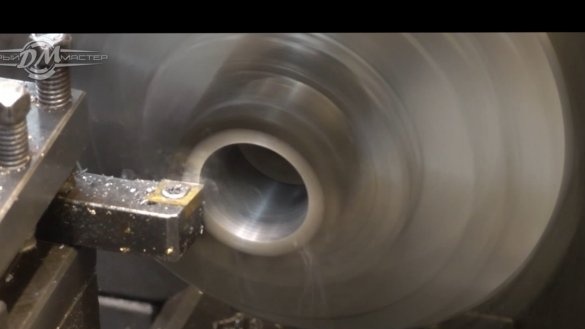

Further, using the same lathe, it is necessary to manufacture a sleeve that we will weld to this workpiece.

The final processing will also be done on a lathe. First, make a through hole in the part, and then bore it to the desired size along with the welded sleeve.

To process the back of the part, the master machined the mandrel, on which the part must be fixed with super-glue. After which it can be removed without much difficulty simply by heating with a conventional gas burner.

Now only cosmetic work remains.

And finally, the detail looks like this:

The resulting detail looks very similar to the carburetor flange from a motorcycle.

Finally, we proceed to the manufacture of the last part. It is the simplest in our homemade design today. Here it is necessary to make a hole in the middle, in this case with a diameter of 20 mm and make a couple of cuts.

Now we drill 2 more holes, in which it is further necessary to cut the m6 thread, and since the screws are flush with us, we countersink them from the bottom.

That's all, all the parts are made, you can proceed with the assembly of our device, and then proceed to the tests.

Here is the beauty we finally got:

The Americans are installing the resulting milling tool in their favorite Dremel drill, but the author plans to use it with his home-made Profile type machine.

Getting started testing.

As you can see, the resulting device turned out to be quite working and for small works it will be simply irreplaceable. But the author believes that the movable part needs a little refinement, it is necessary to weld a pair of bushings under the screws to minimize backlash. That's all. Thank you for attention. See you soon!

Author's video: